A kind of cooling mould and method of cooling steel ingot

A technology for steel ingots and molds, applied in the field of cooling molds and cooling steel ingots, can solve problems such as unsatisfactory quality of extra-thick plate steel ingots, and achieve the effects of eliminating shrinkage defects, promoting uniformity of temperature and composition, and improving isotropy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The above technical features and advantages of the present invention will be clearly and completely described below with reference to the accompanying drawings. Obviously, the described embodiments are only some of the embodiments of the present invention, but not all of the embodiments.

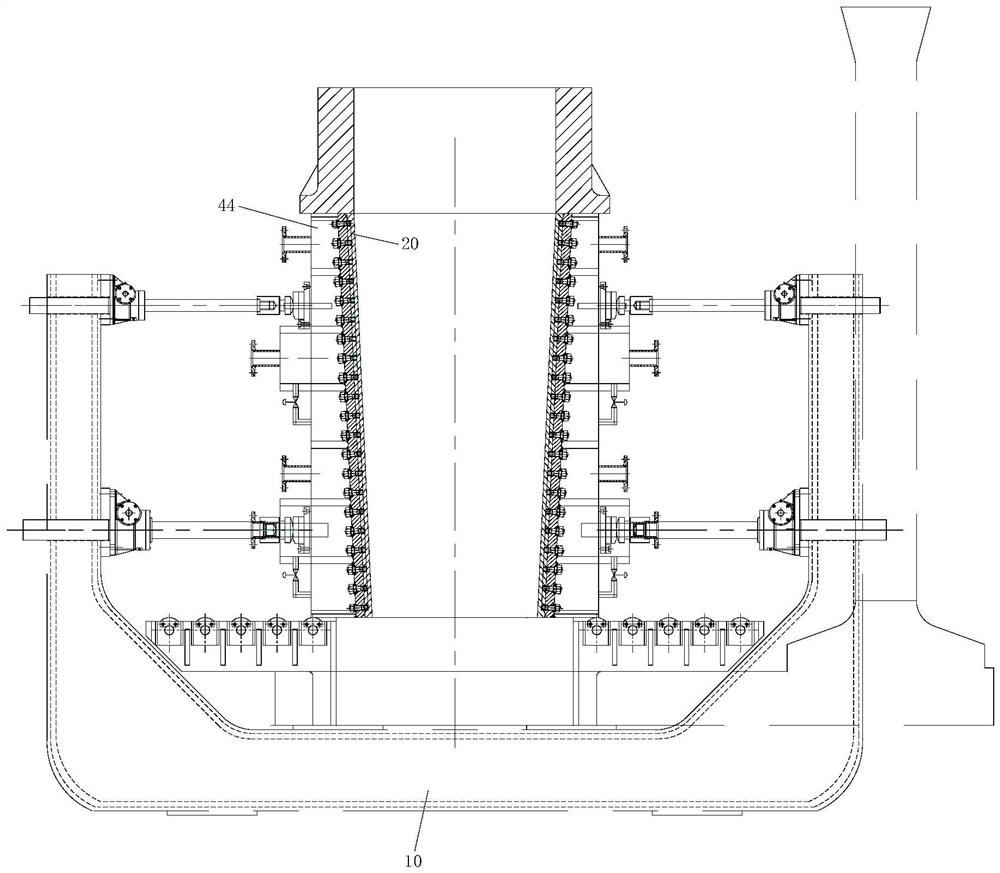

[0060] see figure 1 As shown, the present invention proposes a cooling mold, the cooling mold includes a casting base 10 and a condensation wall 20, the condensation wall 20 is sealed on the casting base 10, and is enclosed with the casting base 10 to form a casting cavity with an upper opening, the casting cavity For accommodating molten steel to be cooled, the condensation wall 20 includes at least two cooling layers arranged in sequence along the vertical direction.

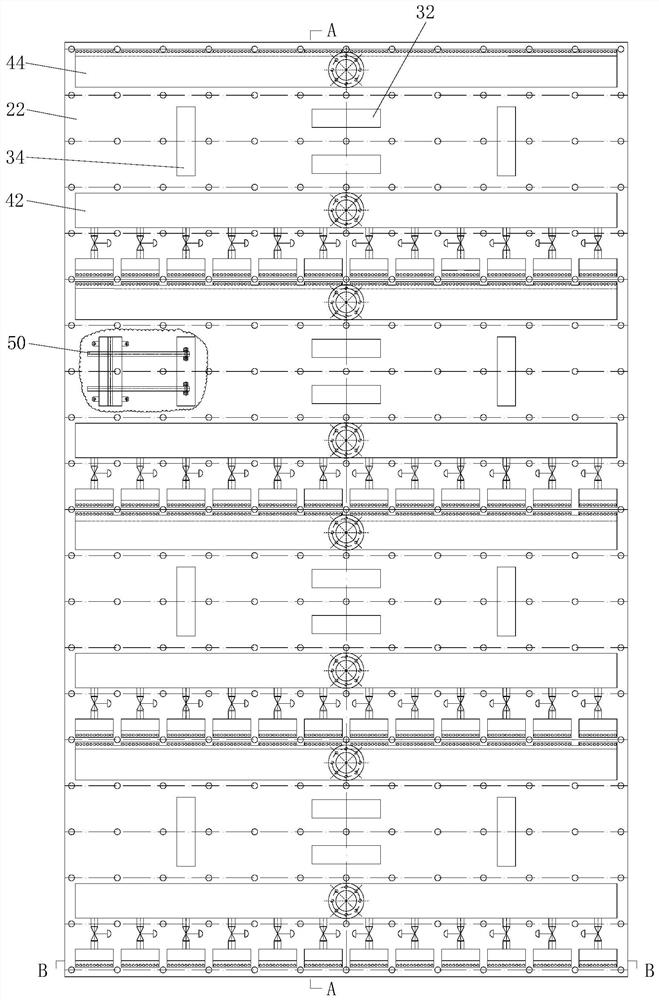

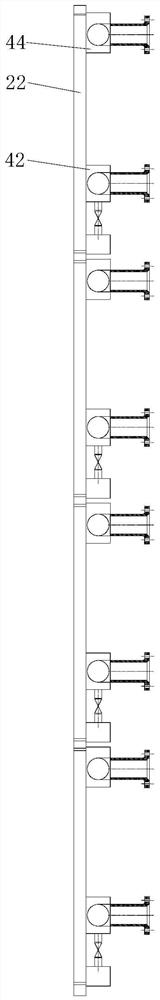

[0061] see figure 2 As shown, the cooling mold also includes at least two pairs of electromagnetic induction components arranged on the outside of the condensation wall 20, each pair of electromagnetic induction com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com