Composite split type high-pressure sealing pair

A high-pressure sealing, split-type technology, applied in the direction of lift valves, engine components, mechanical equipment, etc., can solve the problems of high engine working pressure, shedding, large deformation of non-metallic sealing rings, etc., to ensure effective sealing, reasonable structure, and improved The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

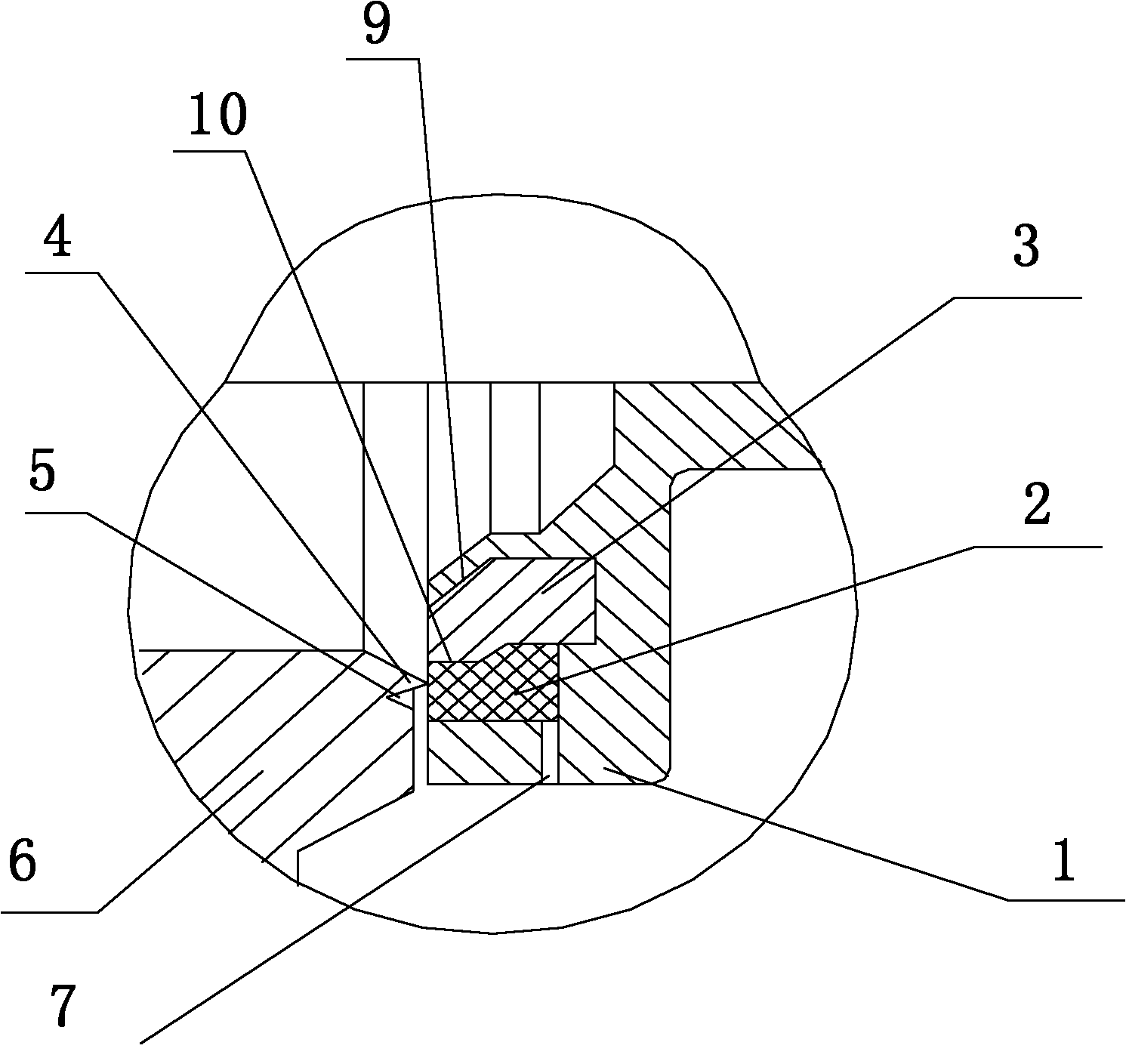

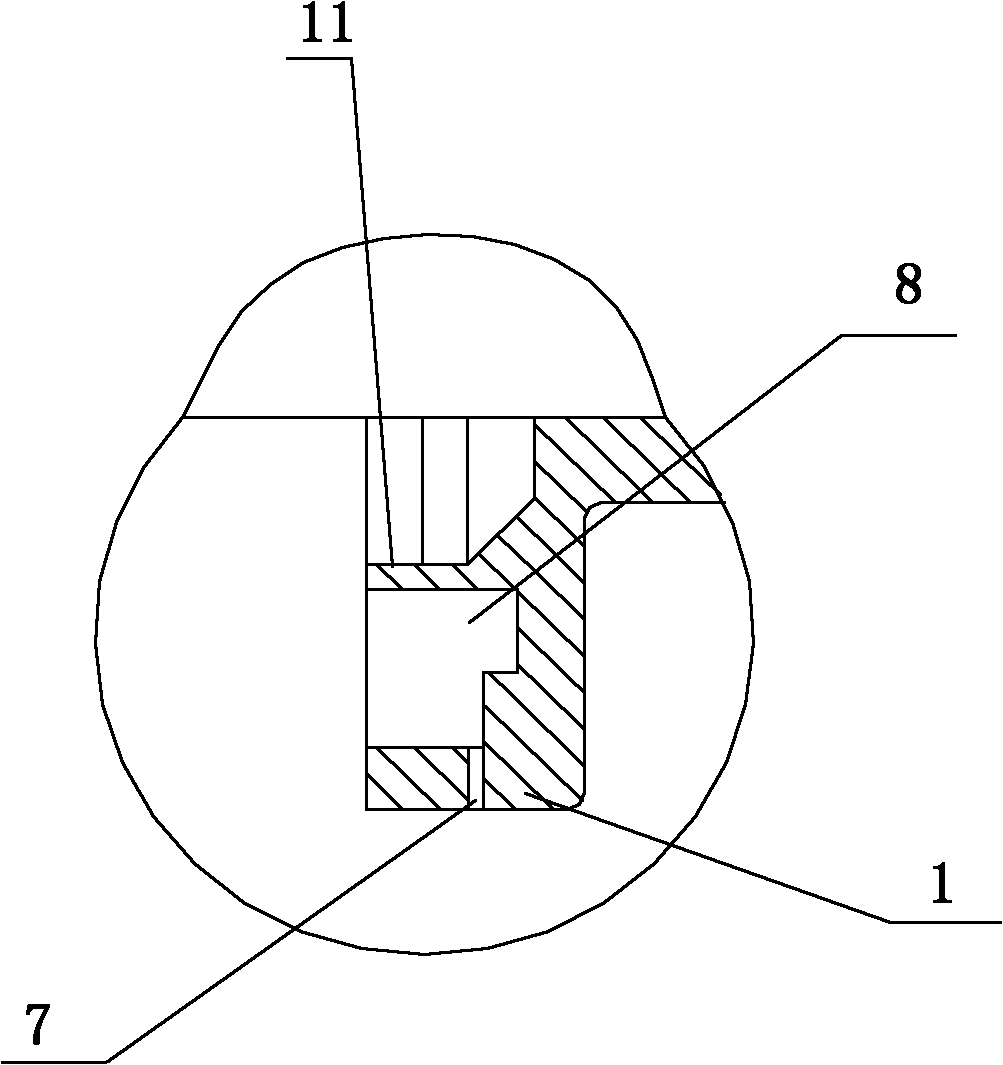

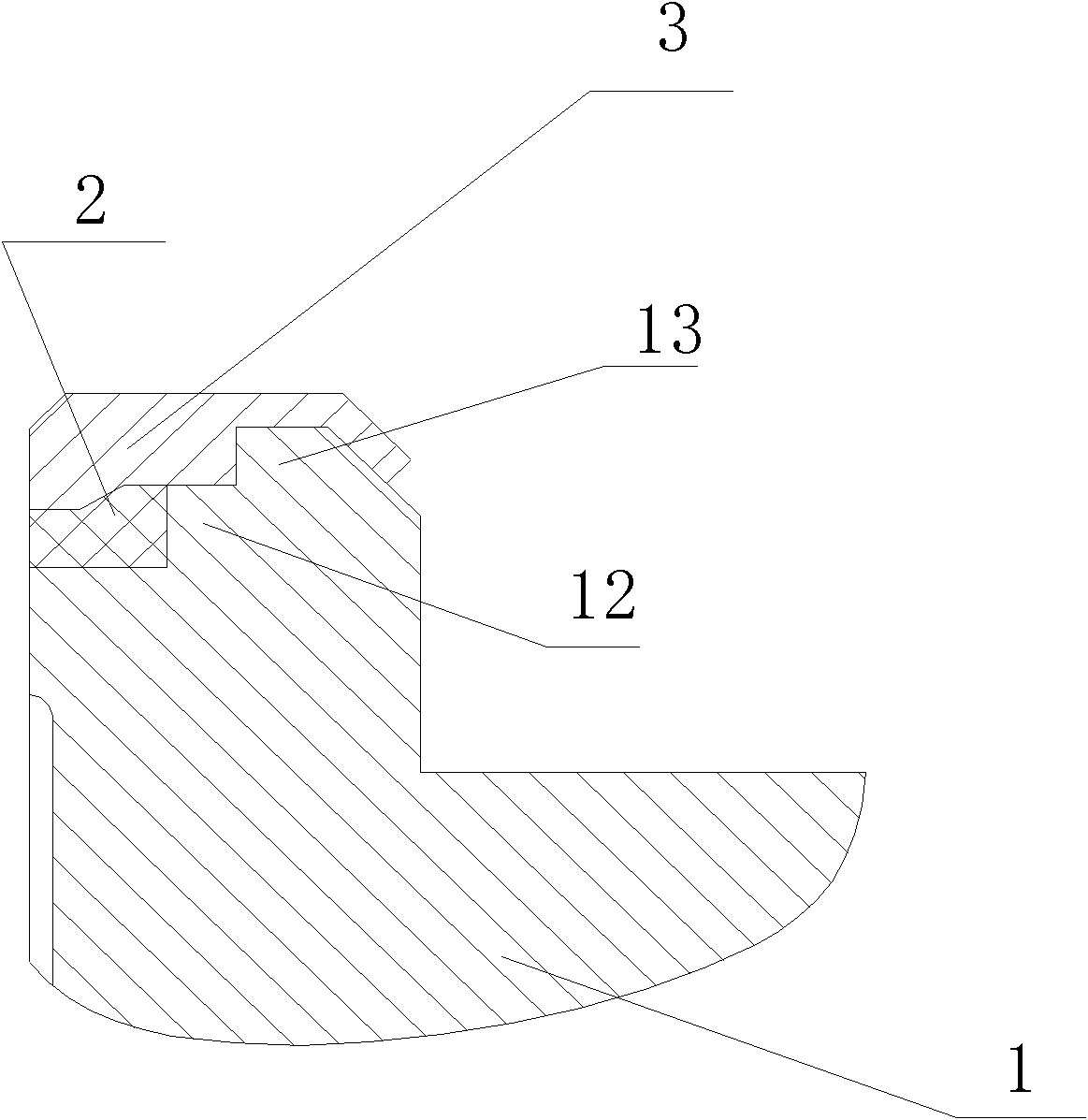

[0016] see figure 1 As shown, the structure diagram of the composite split high-pressure sealing pair of the present invention is also a preferred embodiment of the present invention. It is mainly composed of a valve seat 6, a valve core substrate 1, a valve core non-metallic sealing ring 2, a metal fixing ring 3, and the like.

[0017] The composite split high-pressure sealing pair provided by the present invention includes a valve seat 6 and a valve core assembly. The valve core assembly includes a valve core base 1, a non-metallic sealing ring 2 and a metal fixing ring 3; Groove 8, non-metallic sealing ring 2 and metal fixed ring 3 are arranged in annular sealing groove 8; metal fixed ring 3 is arranged on the inner side of non-metallic sealing ring 2; Angle 9; the position corresponding to the outer surface of the metal fixing ring 3 and the chamfer 9 is provided with an annular boss 10; the outer diameter of the annular boss 10 is slightly larger than the inner diameter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com