Aerosol generating product with composite form plugging piece

An aerosol generation and aerosol generation technology, which is applied to tobacco and other directions, can solve the problems of low production efficiency, increased cost, inconvenience, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] The present embodiment prepares a multi-stage aerosol generating product according to preparation method 2, which comprises the following steps:

[0081] Step 1, the preparation of the mouth stick:

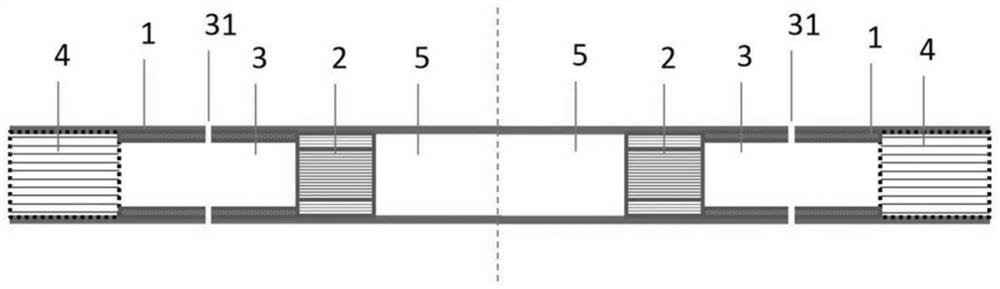

[0082] The blocking element 2 and the filter element 4 are wrapped by the outer pipe 1, the blocking element 2 and the filter element 4 are spaced apart by a first axial length, and the length is defined by the outer pipe 1 to define the cavity section 3,

[0083] One end of the blocking member 2 away from the cavity section 3 is defined by the outer tube 1 to define an aerosol-generating matrix containing cavity 5;

[0084] Step 2, the filling of the aerosol generating material:

[0085] The nozzle rod is in a vertical vertical state, that is, a state vertical to the horizontal plane, wherein the aerosol generation substrate accommodating cavity 5 is vertically upward, and the flowing aerosol generation material is squeezed into the aerosol generation matrix accommodating...

Embodiment 2

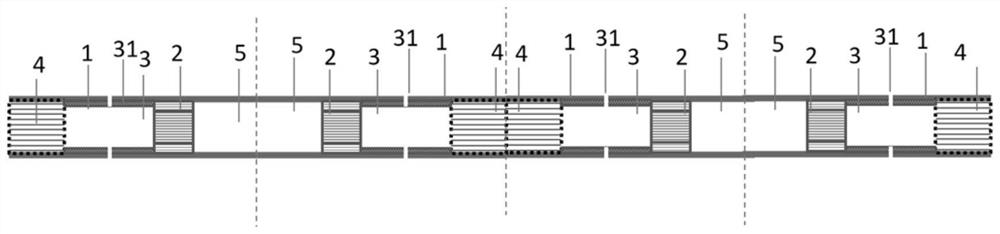

[0106] In this embodiment, a multi-stage aerosol generating product is prepared according to preparation method 2. The difference between this embodiment and embodiment 1 is: 1. In step 1, the nozzle rod can be divided into 4 nozzle rods, and the 4 nozzle rods pass through The filter element 4 is connected with the aerosol-generating substrate accommodating cavity 5; at this time, there is also a slitting step between step 1 and step 2, and the connected filter element 4 and the connected aerosol-generating matrix accommodating cavity 5 are cut to separate the mouth The stick is cut into 4 mouth sticks. The axial length of the filter element at the connection point is twice the axial length of the filter element in a single nozzle stick. Similarly, the axial length of the aerosol-generating matrix accommodating cavity reserved at the connection point is the aerosol generation in a single nozzle stick. The matrix contains twice the axial length of the cavity. So that each mout...

Embodiment 3

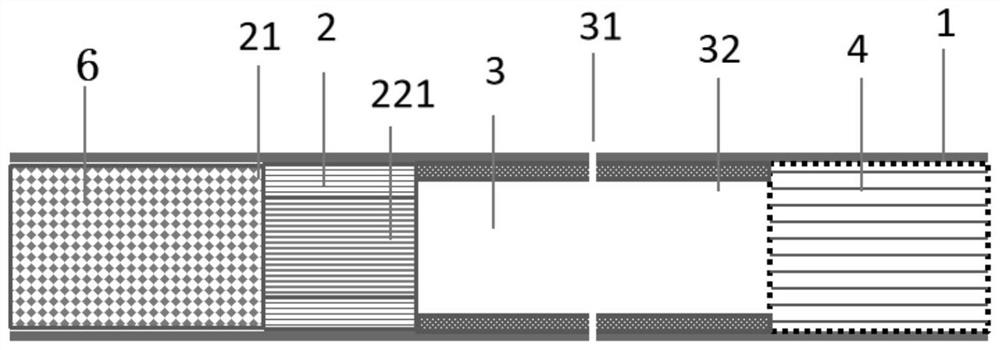

[0108] In this embodiment, a multi-stage aerosol generating product is prepared according to preparation method 1, and the structure of the blocking member in the aerosol generating product is the same as that in embodiment 1, which includes the following steps:

[0109] Step 1, the preparation of the mouth stick:

[0110] The blocking element 2 and the filter element 4 are wrapped by the outer pipe 1, the blocking element 2 and the filter element 4 are spaced apart by a first axial length, and the length is defined by the outer pipe 1 to define the cavity section 3,

[0111] One end of the blocking member (2) away from the cavity section 3 is defined by the outer tube 1 to define an aerosol-generating matrix containing cavity 5;

[0112] Step 2, filling of the aerosol generation substrate 6:

[0113] The nozzle bar is in a vertical state, that is, a state perpendicular to the horizontal plane, wherein the aerosol-generating substrate accommodating chamber 5 is vertically upw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com