Practical bottle neck

A bottle nozzle, a practical technology, applied in the field of bottle nozzles, can solve the problems of high cost, irregular liquid spraying, poor flow control, etc., and achieve the effect of simple structure and stable flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

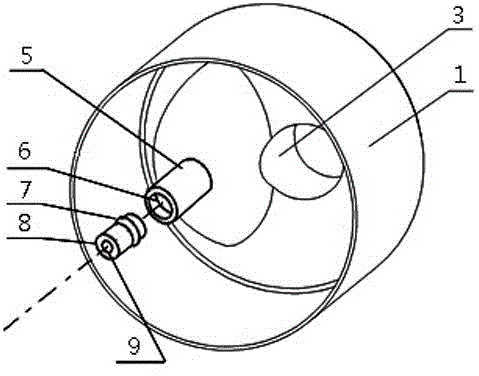

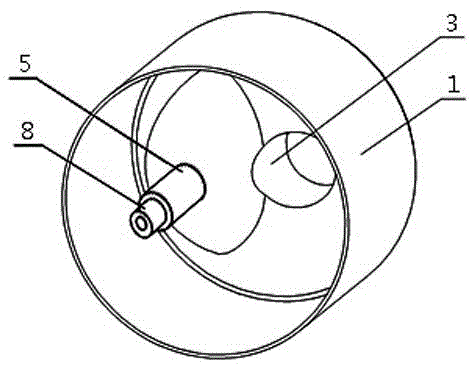

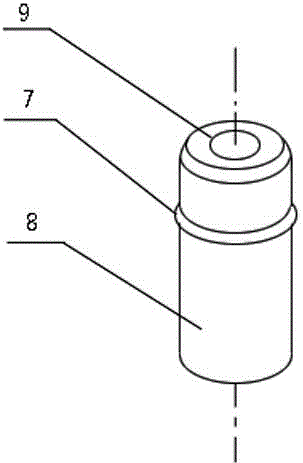

[0059] as attached figure 1 , 2 , 3, 4, 5, and 6, a practical bottle mouth, which includes a bottle mouth body 1 provided with a septum 2, an air inlet 4 and a liquid outlet 3 arranged on the septum 2, the The spacer 2 is arranged in a stepped groove shape, and the present invention is a secondary return flow tank. The air inlet 4 is arranged at the bottom of the groove of the spacer 2, and the lower end of the air inlet 4 is provided with a fixed connection with the spacer 2. The air inlet pipe base 5, the air inlet pipe base 5 is equipped with an air inlet pipe 8, the air inlet 9 of the air inlet pipe 8 communicates with the air inlet 4, and the air inlet 4 is provided with a detachable seal Parts sealing nail 10. as attached figure 2 with 5 As shown, the outer wall of the air intake pipe 8 of the present invention is provided with an air intake pipe flange 7, and the air intake pipe base 5 is provided with an air intake pipe clamping groove 6 that matches the air intak...

Embodiment 2

[0062] as attached figure 1 , 2 , 3, 4, 5, and 6, a practical bottle mouth, which includes a bottle mouth body 1 provided with a septum 2, an air inlet 4 and a liquid outlet 3 arranged on the septum 2, the The spacer 2 is arranged in a stepped groove shape, and the present invention is a secondary return flow tank. The air inlet 4 is arranged at the bottom of the groove of the spacer 2, and the lower end of the air inlet 4 is provided with a fixed connection with the spacer 2. The air inlet pipe base 5, the air inlet pipe base 5 is equipped with an air inlet pipe 8, the air inlet 9 of the air inlet pipe 8 communicates with the air inlet 4, and the air inlet 4 is provided with a detachable seal Parts sealing nail 10. as attached figure 2 with 5 As shown, the outer wall of the air intake pipe 8 of the present invention is provided with an air intake pipe flange 7, and the air intake pipe base 5 is provided with an air intake pipe clamping groove 6 that matches the air intak...

Embodiment 3

[0065] as attached figure 1 , 2 , 3, 4, 5, and 6, a practical bottle mouth, which includes a bottle mouth body 1 provided with a septum 2, an air inlet 4 and a liquid outlet 3 arranged on the septum 2, the The spacer 2 is arranged in a stepped groove shape, and the present invention is a secondary return flow tank. The air inlet 4 is arranged at the bottom of the groove of the spacer 2, and the lower end of the air inlet 4 is provided with a fixed connection with the spacer 2. The air inlet pipe base 5, the air inlet pipe base 5 is equipped with an air inlet pipe 8, the air inlet 9 of the air inlet pipe 8 communicates with the air inlet 4, and the air inlet 4 is provided with a detachable seal Parts sealing nail 10. as attached figure 2 with 5 As shown, the outer wall of the air intake pipe 8 of the present invention is provided with an air intake pipe flange 7, and the air intake pipe base 5 is provided with an air intake pipe clamping groove 6 that matches the air intak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com