Ventilating passage for crankcase ventilating system

A crankcase ventilation and ventilation channel technology, which is applied to crankcase ventilation, engine components, machines/engines, etc., can solve the problems of poor separation effect and large separation pressure, so as to improve intake air quality, improve combustion and emissions, The effect of reducing the content of lubricating oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below according to the accompanying drawings, which is a preferred embodiment among various implementations of the present invention.

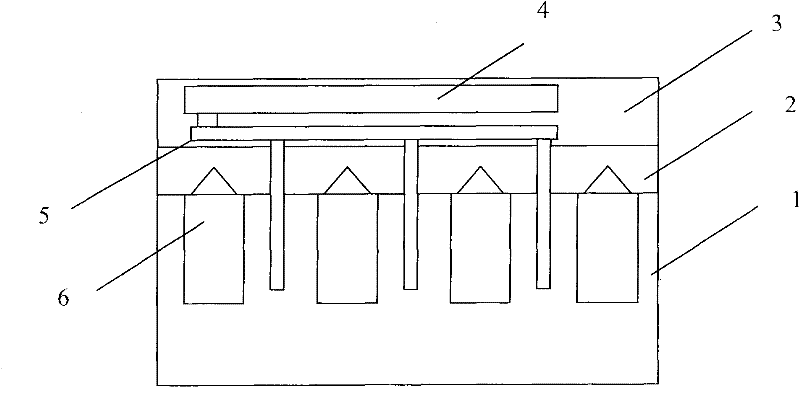

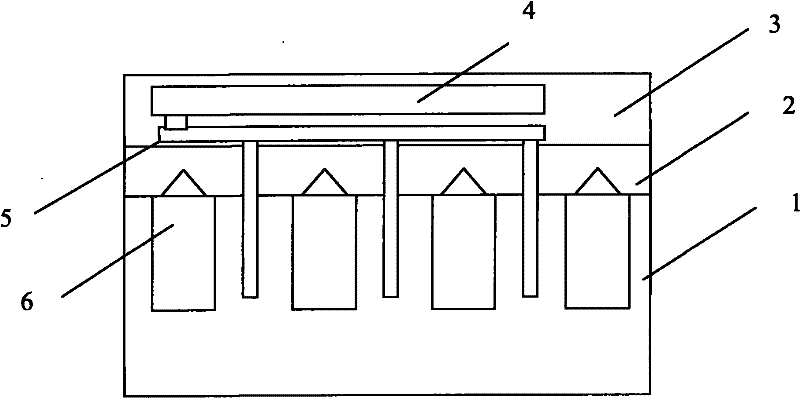

[0021] Refer to attached figure 1 : in the figure

[0022] 1---Cylinder block 2---Cylinder head 3---Cylinder cover 4---Oil-air separator 5---Ventilation channel 6---Cylinder. Ventilation passages are distributed on the cylinder block, cylinder head and cylinder head cover. Inside the cylinder head, a separate ventilation passage is produced through processing to completely avoid direct contact with lubricating oil; inside the cylinder head cover, the passage formed by processing will The oil-air mixture from the cylinder head channel is directly introduced into the inlet of the oil-air separator to avoid direct contact with the lubricating oil; in addition, at the junction of the three parts of the cylinder block, cylinder head and cylinder head cover, the design of the O-ring seal met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com