Hot blowing type snow sweeper based on large-bypass-ratio turbofan engine and snow removing method

A technology of turbofan engine and large bypass ratio, which is used in machinery/engine, snow surface cleaning, mechanical equipment, etc., can solve the problems affecting snow removal and surge, and achieve the reduction of snow removal cost, large displacement, and improved snow removal. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0040]It should be noted that the structures, proportions, sizes, etc. shown in this specification are only used to cooperate with the content disclosed in the specification for the understanding and reading of those familiar with this technology, and are not used to limit the conditions for the implementation of the present invention , any modification of structure, change of proportional relationship or adjustment of size shall still fall within the scope covered by the technical content disclosed in the present invention without affecting the effect and purpose of the present invention. .

[0041] At the same time, terms such as "upper", "lower", "left", "right", "middle" and "one" quoted in this specification are only for the convenience of description and are not used to limit this specification. The practicable scope of the invention and the change or adjustment of its relative relationship shall also be regarded as the practicable scope of the present invention without ...

Embodiment 1

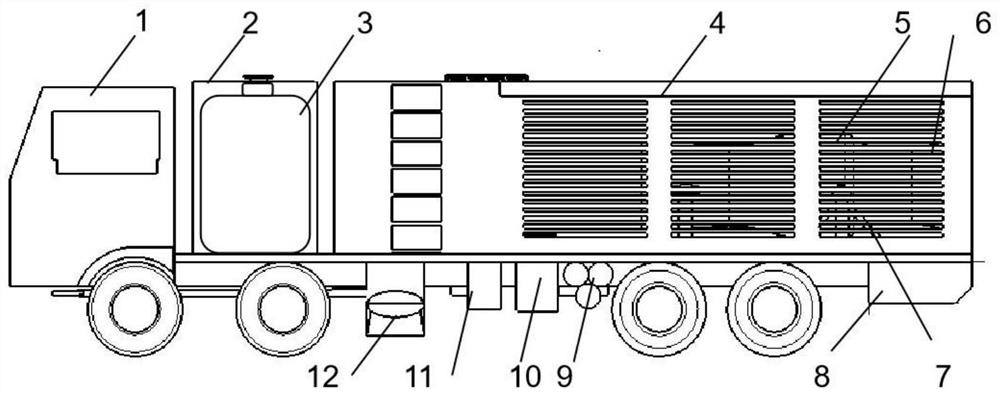

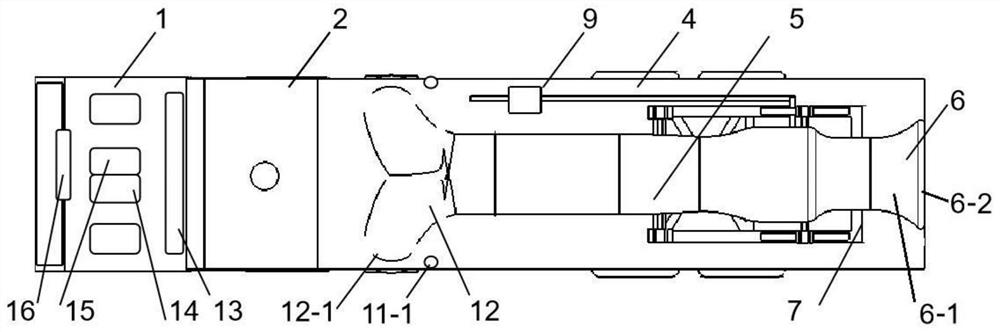

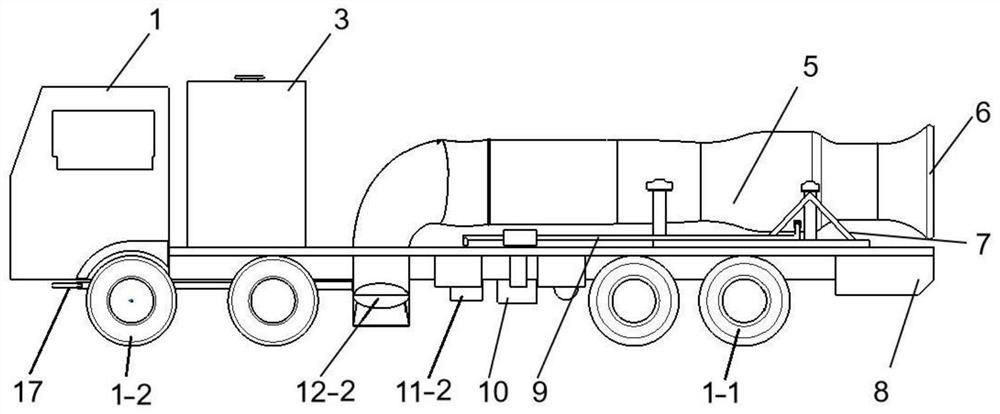

[0043] Such as Figure 1~3 As shown, the present invention discloses a hot blowing snow removal vehicle based on a turbofan engine with a large bypass ratio, including a car chassis 1, a front compartment 2, a fuel tank 3, a rear compartment 4, a turbofan engine 5, and an air intake assembly 6 , power supply assembly 8, oil supply assembly 9, hydraulic starting assembly 10, jet snow removal assembly 12 and control assembly, the upper end surface of the automobile chassis 1 is fixed with a front compartment 2 and a rear compartment 4, and a fuel oil tank 3 is arranged in the front compartment 2, and the rear compartment 4 is provided with a turbofan engine 5, an air intake assembly 6 and a jet snow removal assembly 12, one end of the turbofan engine 5 is connected to the air intake assembly 6, the other end of the turbofan engine 5 is connected to the jet snow removal assembly 12, and one end of the oil supply assembly 9 is connected to The fuel oil tank 3, the other end of the...

Embodiment 2

[0045] Such as Figure 4 As shown, preferably, the turbofan engine 5 includes a low-pressure compressor 5-1, a partition casing 5-2, a high-pressure compressor 5-3, a combustion chamber 5-4, a turbine device 5-5, a mixer 5- 6. The nozzle 5-7 and the middle casing 5-10, one end of the low-pressure compressor 5-1 is connected to the intake assembly 6, the other end of the low-pressure compressor 5-1 is connected to the partition casing 5-2, and the partition casing 5-2 The center is connected to the high-pressure compressor 5-3, and the outer side of the high-pressure compressor 5-3 is connected to the middle casing 5-10, and the other end of the middle casing 5-10 communicates with the nozzle 5-7, and the other end of the high-pressure compressor 5-3 Connect the combustion chamber 5-4, the other end of the combustion chamber 5-4 is connected to the turbine device 5-5, the other end of the turbine device 5-5 is connected to the mixer 5-6, and the mixer 5-6 is arranged in the noz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com