OLED display panel and manufacturing method thereof, and OLED display apparatus

A technology of display panel and blocking block, which is applied in the field of OLED display, can solve the problems of low FMMMASK aperture ratio, FMMMASK aperture blockage, and OLED display panel line defects, so as to reduce one-time mask evaporation process, improve quality, and reduce line defects and color mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order for those skilled in the art to better understand the technical solutions of the present invention, the OLED display panel, its manufacturing method, and OLED display device provided by the present invention will be described in detail below with reference to the accompanying drawings.

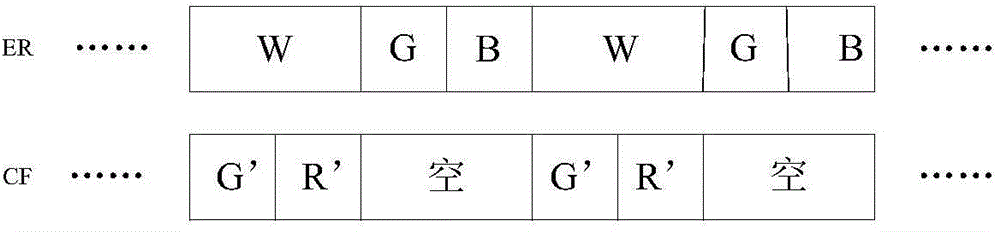

[0036] Figure 1a A schematic structural diagram of the OLED display panel provided by the first embodiment of the present invention. see Figure 1a , the OLED display panel provided in this embodiment includes a light-emitting layer ER and a color filter CF. Wherein, the light-emitting layer ER includes a white sub-pixel W and a color sub-pixel, the size of the white sub-pixel W is equal to the sum of the sizes of at least two color sub-pixels, and the number of color sub-pixels is less than the number of primary colors forming a color. In this embodiment In the example, the number of primary colors forming a color is single, which are red, green and blue respectively; the col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com