Method of manufacturing display device, repairing method, and liquid crystal display panel

A display device and substrate technology, applied in the field of liquid crystal display panels and liquid crystal display display devices, can solve the problems of broken data lines, lowering the qualification rate of liquid crystal display panels, difficult to repair, etc., to reduce difficulty, improve display quality, and improve finished products. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the drawings.

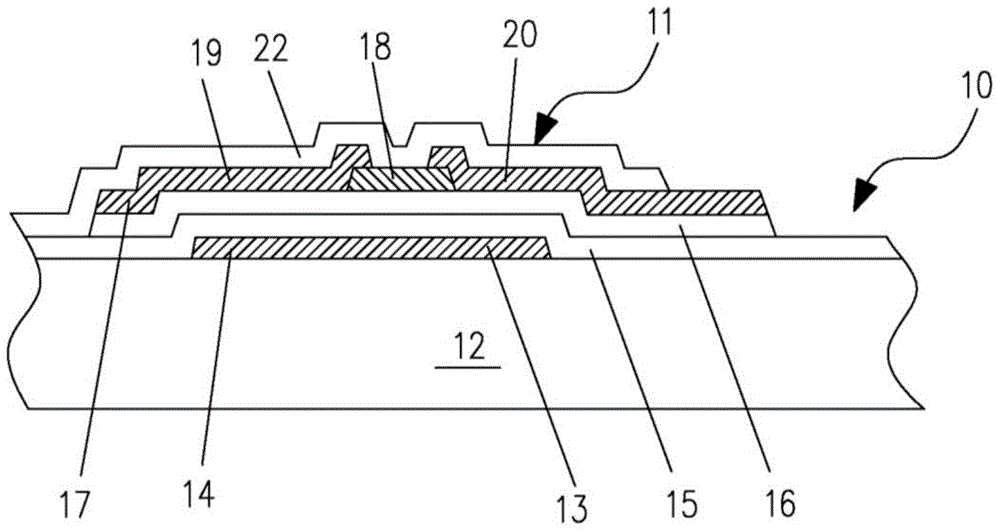

[0027] figure 1 The layered structure diagram of the display device 10 according to the present invention is schematically shown. A thin film transistor 11 is provided on the display device 10. The thin film transistor 11 is a common switching element in the field of liquid crystal display, and its arrangement in the display device 10 is well known to those skilled in the art, and will not be repeated here. Here, the manufacturing method of the thin film transistor 11 will be mainly described.

[0028] The preparation of the thin film transistor 11 includes the following steps.

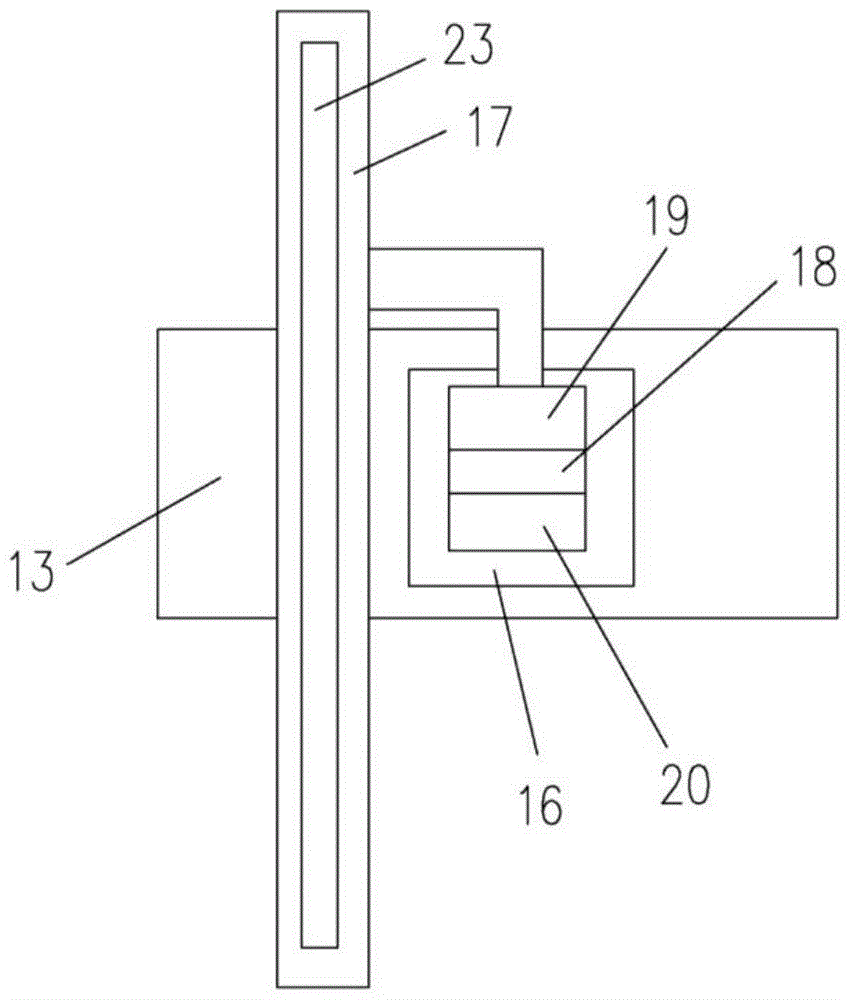

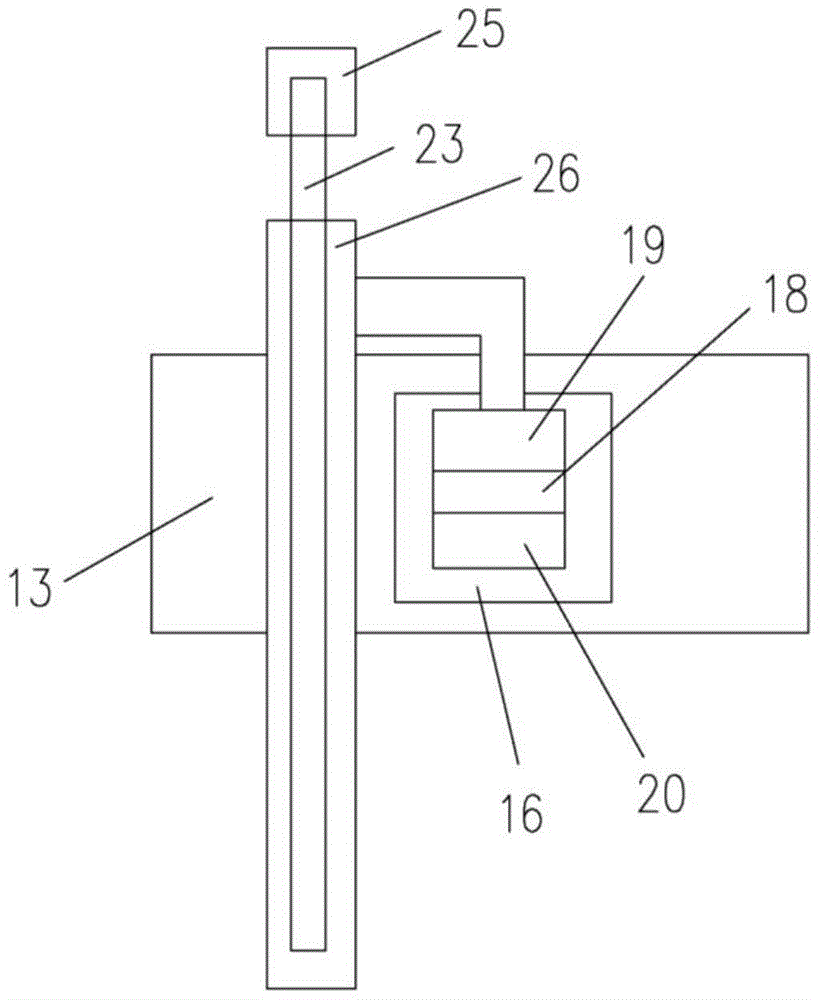

[0029] First, the gate 13 and the scan line 14 are arranged on the substrate 12, and then the first insulating layer 15 is arranged on the gate 13 and the scan line 14, and then the semiconductor layer 16 is arranged on the first insulating layer 15, wherein the semiconductor layer 16 is Above the gate 13 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com