Method for reversing gas humidity on surface of rock core by using cationic fluorocarbon surfactant

A wetting reversal, sandstone technology, applied in the direction of chemical instruments and methods, earth drilling, drilling composition, etc., can solve the problems of danger, inconvenient use, formation damage, etc., to avoid pollution, safe and convenient to use , good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The wetting inversion treatment agent is an aqueous solution composed of cetyltrimethylammonium bromide and cationic fluorocarbon surfactant FC911, the mass percentage of FC911 is 0.1%, and the mass percent of cetyltrimethylammonium bromide and FC911 The ratio is 1:99.

[0040] Sandstone surface wetting reversal test method: first slice the sandstone core to make a core slice with a diameter of 2.5cm and a thickness of about 1cm, and polish the surface smooth. Then the core slices were cleaned with ethanol and acetone. Soak the core piece in the wetness inversion treatment agent, treat it at 25° C. for 10 hours, and then take out the core piece to dry or oven dry at room temperature.

[0041] The wettability of the surface of the core slice is measured using the stop-drop method, and the specific measurement method is as follows:

[0042] Put the processed core piece on the instrument stage, then suck water and oil with a micro-sampler, and drop water droplets and oil...

Embodiment 2

[0046] As described in Example 1, the difference is that the mass concentration of FC911 in the wetting inversion treatment agent solution is 0.2%.

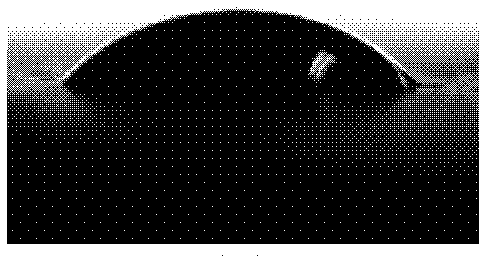

[0047] This embodiment measures the contact angle of the rock core surface after the treatment, and the contact angle of the salt water\air\sandstone system is 72° (such as image 3 shown), the contact angle of n-decane\air\sandstone system is 68° (such as Figure 9 shown).

Embodiment 3

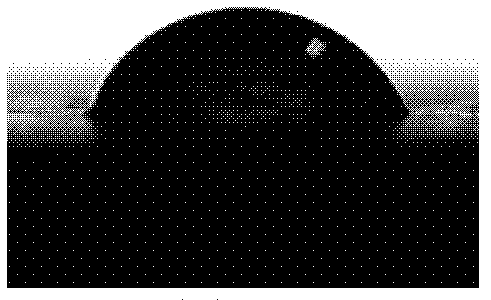

[0049] As described in Example 1, the difference is that the mass concentration of FC911 in the wetting inversion treatment agent solution is 0.3%. The surface contact angle of the rock core is measured after the treatment of this embodiment, and the contact angle of the salt water\air\sandstone system is 80° (such as Figure 4 shown), the contact angle of n-decane\air\sandstone system is 74° (such as Figure 10 shown).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com