Impermeable wear-resistant concrete and preparation method thereof

A technology of concrete and preparation equipment, which is applied in the direction of clay preparation equipment, mixing operation control, chemical instruments and methods, etc. It can solve the problems of automatic weighing and unloading, agglomeration and agglomeration, etc., achieve novel structure, improve impermeability, The effect of improving workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

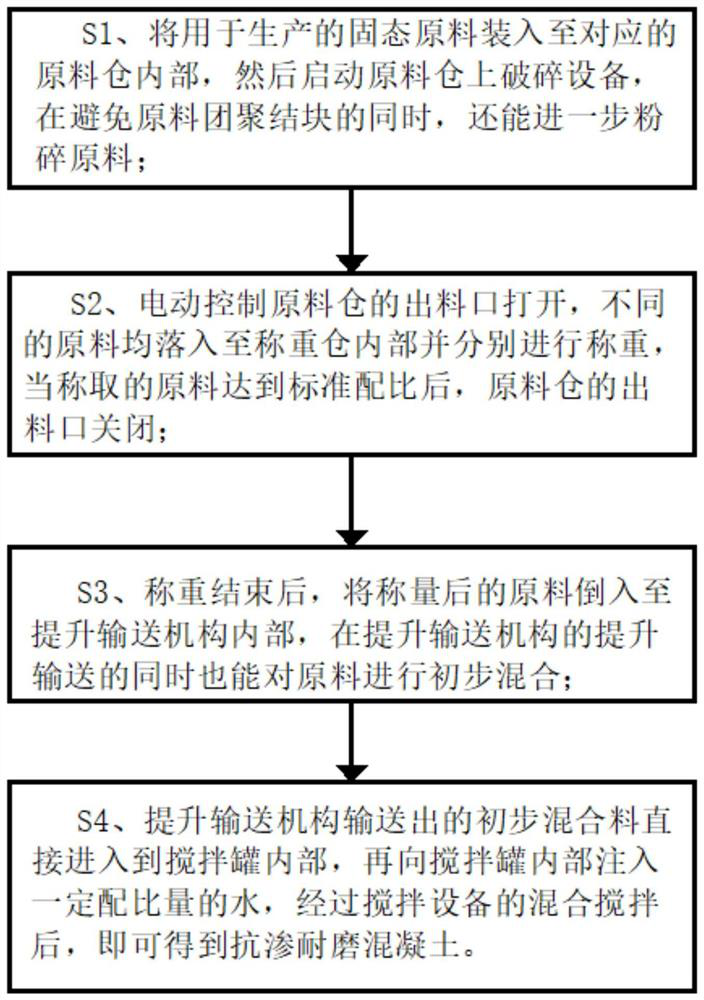

[0052] Such as figure 1 As shown, a kind of impermeable and wear-resistant concrete includes the following raw materials in parts by weight: 140 parts of cement, 50 parts of fly ash, 38 parts of blast furnace slag, 110 parts of quartz sand, 230 parts of crushed stone, 6 parts of carbon black, fiber filler 1.4 parts, 4 parts of sodium alkylbenzene sulfonate, 4 parts of water reducer, 6 parts of polyvinyl alcohol, 2 parts of anti-seepage and wear-resistant composition and 85 parts of water; wherein the cement is Portland cement, aluminate One or more of cement and sulphoaluminate cement, the crushed stone is continuously graded basalt crushed stone with a particle size of 5-30mm, and the mud content is <0.3%, and the fiber filler is polyester fiber, wood The cellulose fiber and glass fiber are compounded according to the mass ratio of 1:1:2, the water reducer is sodium lignosulfonate, and the impermeable composition is calcium formate, sodium rosinate, and triethanolamine accord...

Embodiment 2

[0066] An anti-seepage and wear-resistant concrete, comprising the following raw materials in parts by weight: 130 parts of cement, 60 parts of fly ash, 55 parts of blast furnace slag, 120 parts of quartz sand, 250 parts of gravel, 6 parts of carbon black, 1.7 parts of fiber filler, 4 parts of sodium alkylbenzene sulfonate, 5 parts of water reducer, 7 parts of polyvinyl alcohol, 4 parts of anti-seepage and wear-resistant composition and 95 parts of water; wherein the cement is Portland cement, aluminate cement, sulfur One or more of aluminate cements, the crushed stones are continuously graded basalt crushed stones with a particle size of 5-30 mm, and the mud content is <0.3%, and the fiber fillers are polyester fibers, lignin fibers, The glass fiber is compounded according to the mass ratio of 1:1:2, the water reducer is sodium lignosulfonate, and the impermeable composition is calcium formate, sodium abietate, and triethanolamine according to the mass ratio of 2:1: 3 compoun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com