Method for carrying out coal gasification regionally by fixed bed

A sub-regional, coal gas technology, applied in fixed bed gasification, chemical industry, manufacturing of combustible gas, etc., can solve the problems of low steam decomposition rate, high carbon residue in slag, waste of resources, etc. The effect of good quality and low carbon residue in slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing:

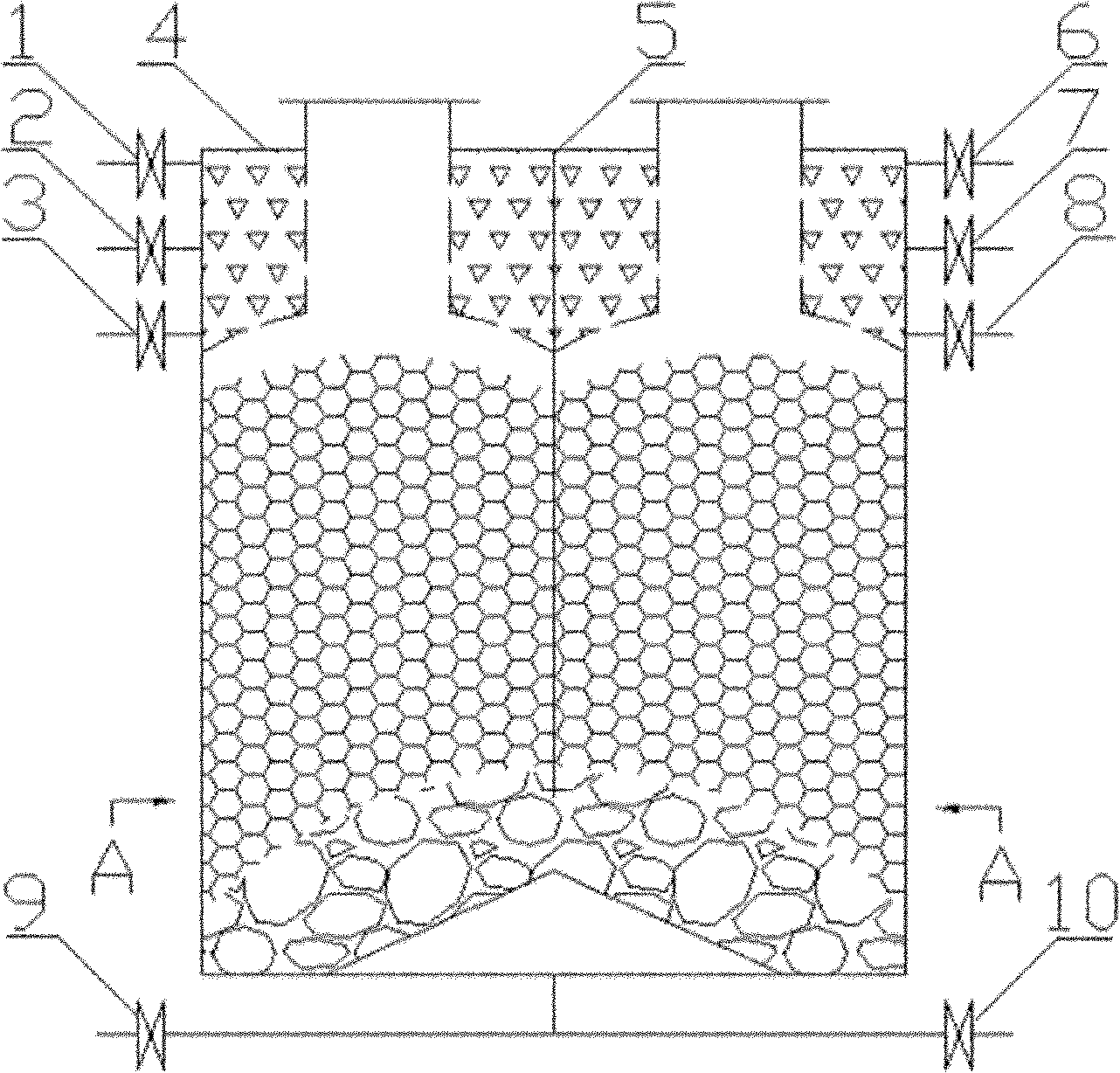

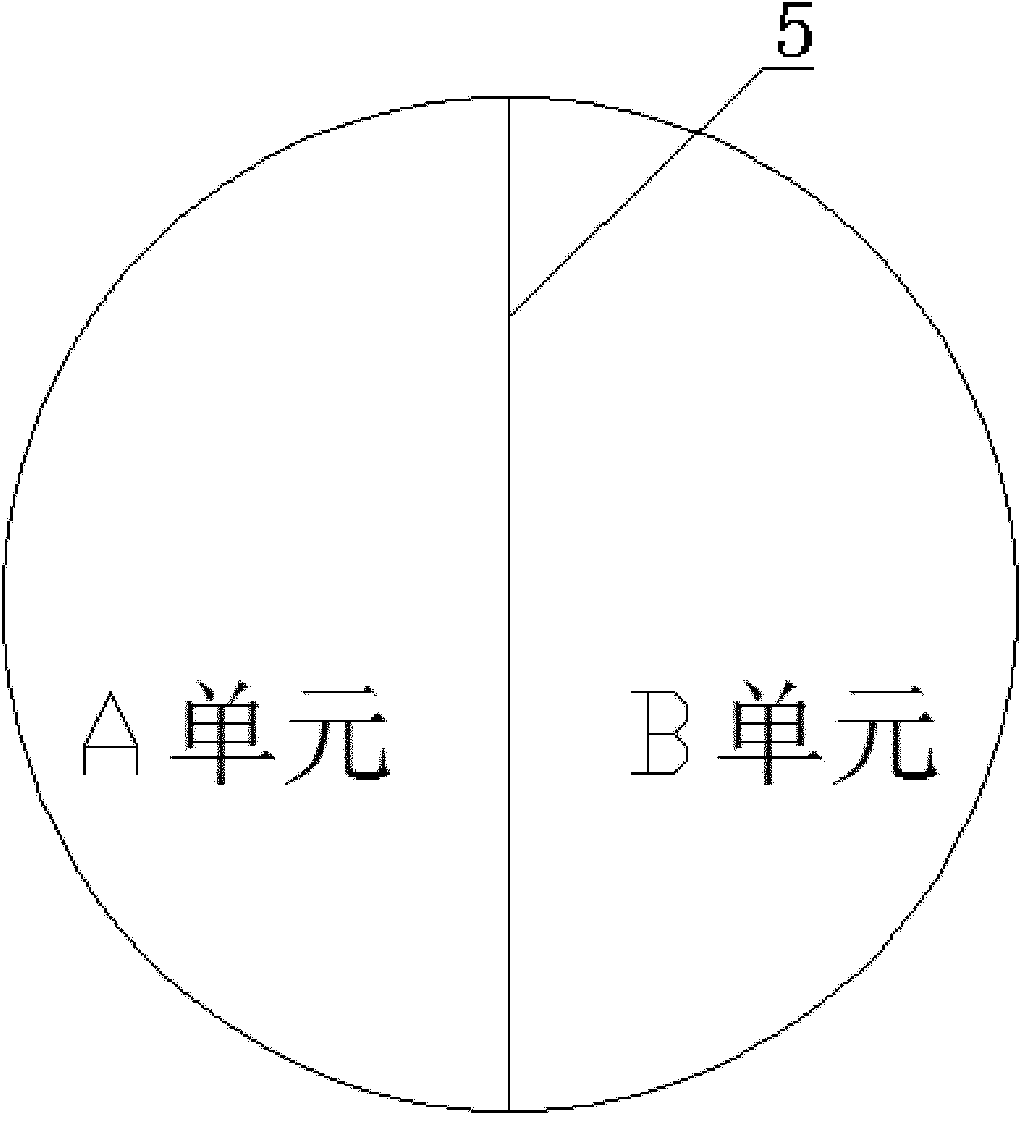

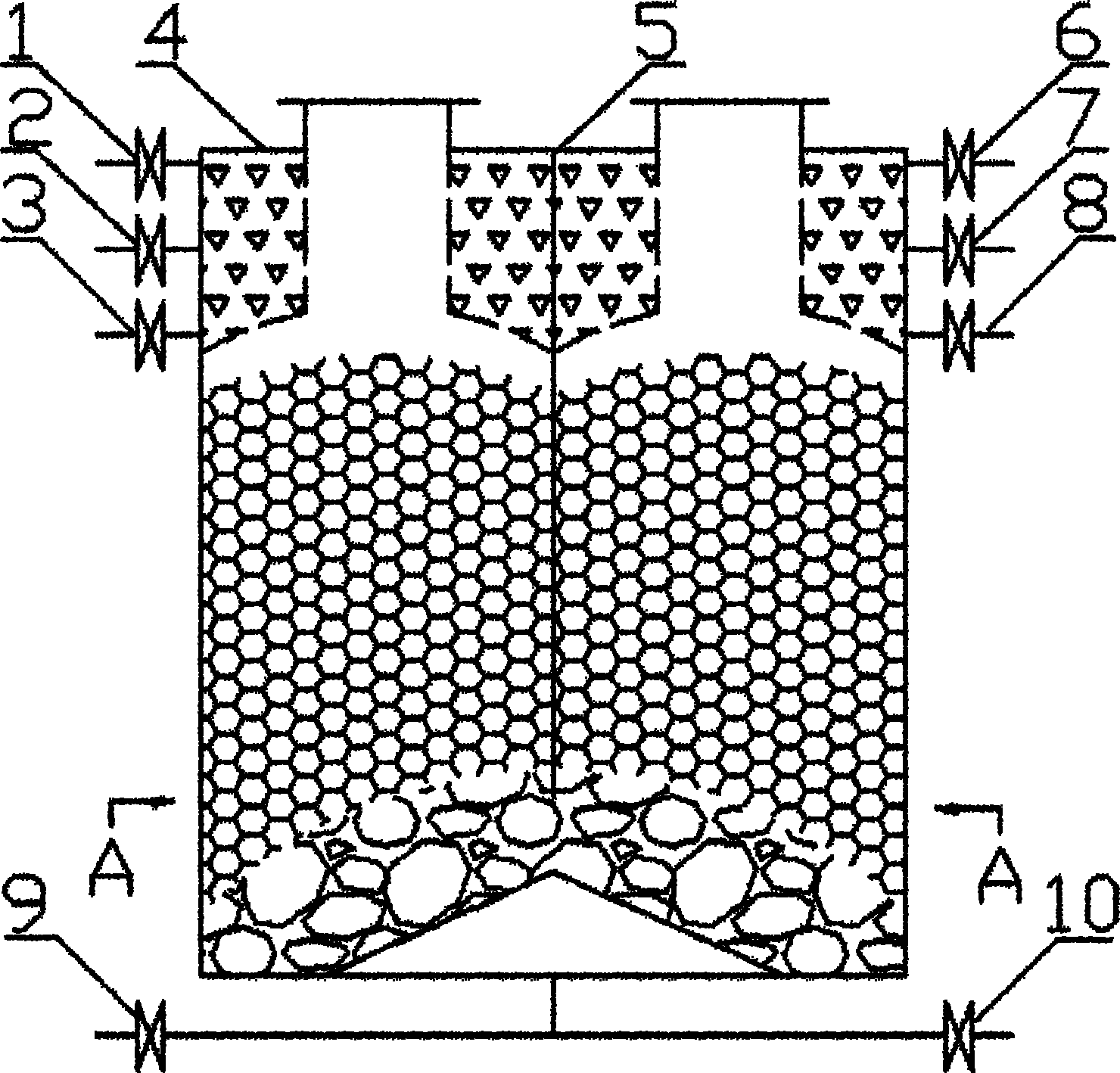

[0015] Such as figure 1 , figure 2 As shown, the present invention divides the middle and upper parts of the gas furnace 4 into two gasification areas A and B through a partition wall 5, and each gasification area is equipped with complete gas valves, steam valves, flue valves, etc. Facilities, the bottom of the gas furnace is equipped with complete blowing valves, nitrogen valves and other blowing facilities. In the blowing stage, the blowing valve at the bottom of the gas furnace and the nitrogen adding valve are opened, the middle and upper flue valves of the gas furnace are both opened, and the other valves are closed. Post-work section treatment; gas production stage (first half stage, second half stage): the nitrogen valve at the bottom of the gas furnace is opened, the gas valve and steam valve in the middle and upper areas of the gas furnace are crossed (first ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com