Biomass gasification centralized safety and early warning air supplying system

A gas supply system and biomass technology, applied in the field of biomass pyrolysis gasification, can solve problems such as low gasification efficiency, difficulty in cleaning dust for workers, insufficient fuel gas production, etc., to improve operational safety and efficiency, and reduce environmental pollution. Secondary pollution and the effect of improving energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

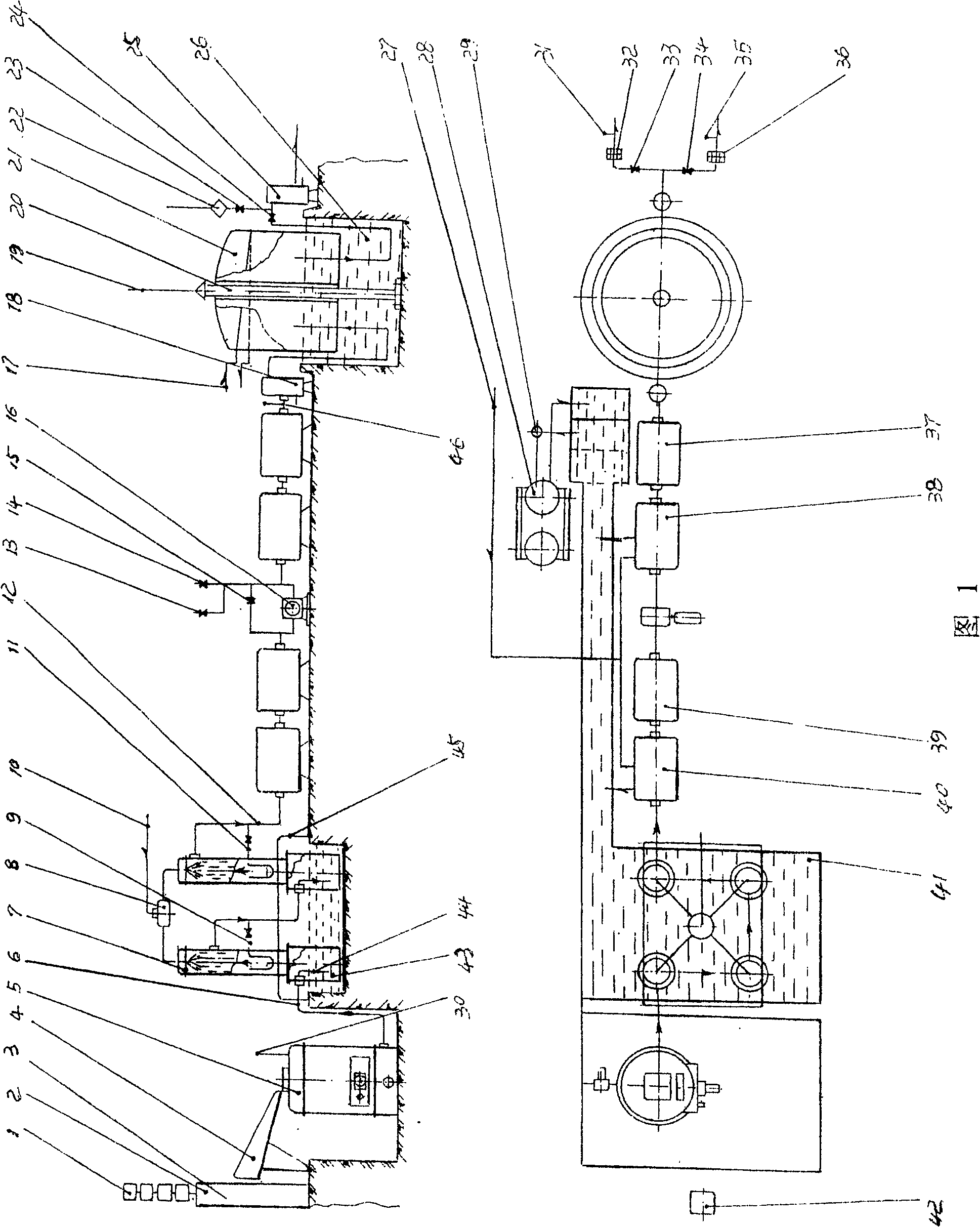

[0076] According to the schematic diagram of Fig. 1, at first, upper spray tank (7) water bath tank (43) water inlet pipe (44) water diversion five-way (8) water inlet pipe (10) gas pipeline (12) is connected by pipeline, Assembled into groups of tower-type water bath spray tanks. Fixed and suspended on the pool (41) by the bracket (45). Use pipes to connect the high-temperature gas outlet pipe (6) to the gasifier (5) and connect the spray filter tank (40) to the medium purification tank (39) to the gas pipeline main fan (16) to the gas control valve (15) to the gas test valve ( 13) Exhaust valve (14) secondary spray filter tank (38) secondary medium purification tank (37) water inlet pipe for spraying (27) gas flow sensor (46) water seal (18) gas storage tank (21) Gas master valve (24) electric valve (23) electric spark igniter (22) gas outlet sewage tank (25) electric valve (33), (34) branch pipe fire arresting net (32), (36) flame sensor (31), (35) Gas supply pipes for us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com