Structure and application method of punching air inlet channel shared by liquid cooling system and environmental control system of airplane

An environmental control system and air intake technology, applied in aircraft parts, transportation and packaging, air handling equipment, etc., can solve the problems of large ram air volume and large compensation loss of aircraft fuel, reduce the total amount of ram air, The effect of overall weight reduction and complexity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

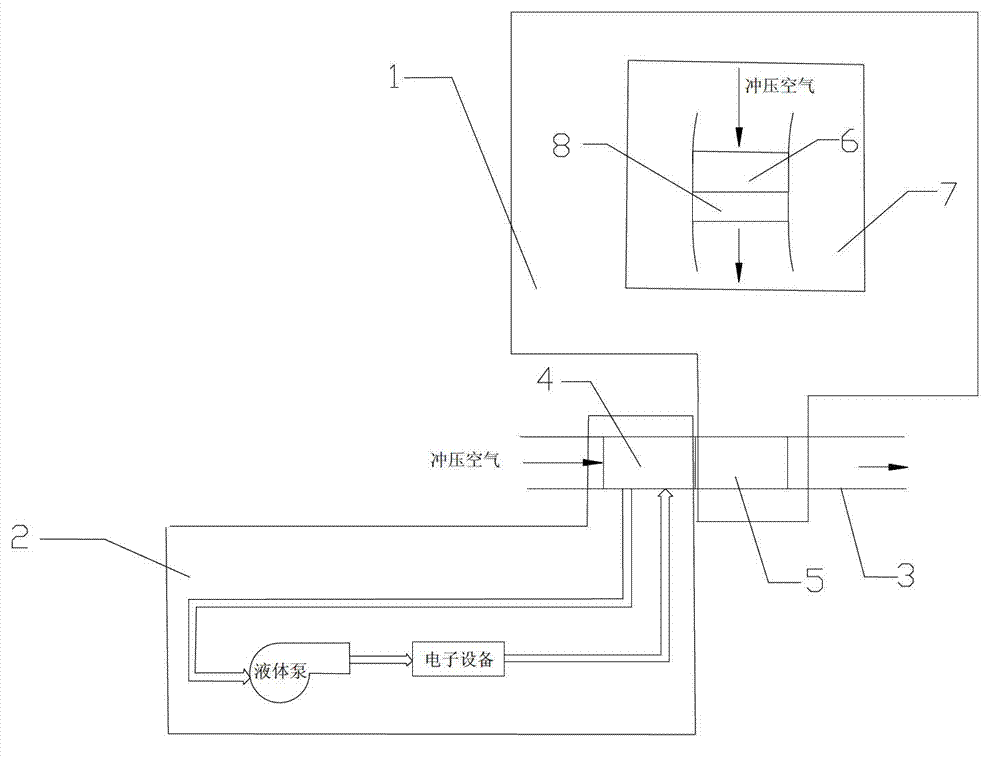

[0020] A structure in which an aircraft liquid cooling system and an environmental control system share a ram air intake is composed of a liquid cooling system 1, an environmental control system 2, and a ram air intake 3; the air-liquid heat exchanger 4 of the liquid cooling system 1 is installed in the The front of the secondary heat exchanger 5 of the control system 2. The primary heat exchanger 6 of the environmental control system 2 is installed in the engine nacelle 7, before the precooler 8; on this basis, the liquid cooling system 1 and the environmental control system 2 share the ram air intake 3, refer to the attached figure 1 , the air-liquid heat exchanger 4 of the liquid cooling system 1 and the secondary heat exchanger 5 of the environmental control system 2 share a ram air intake 3, and the ram air intake 3 is arranged on the top or bottom of the fuselage.

Embodiment 2

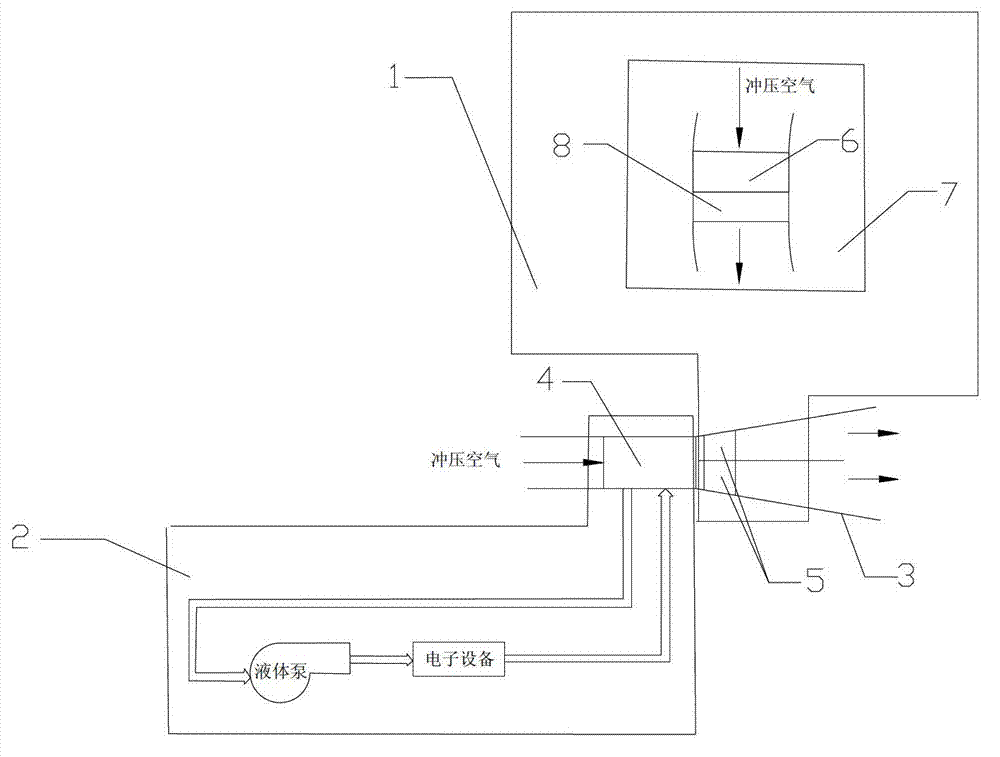

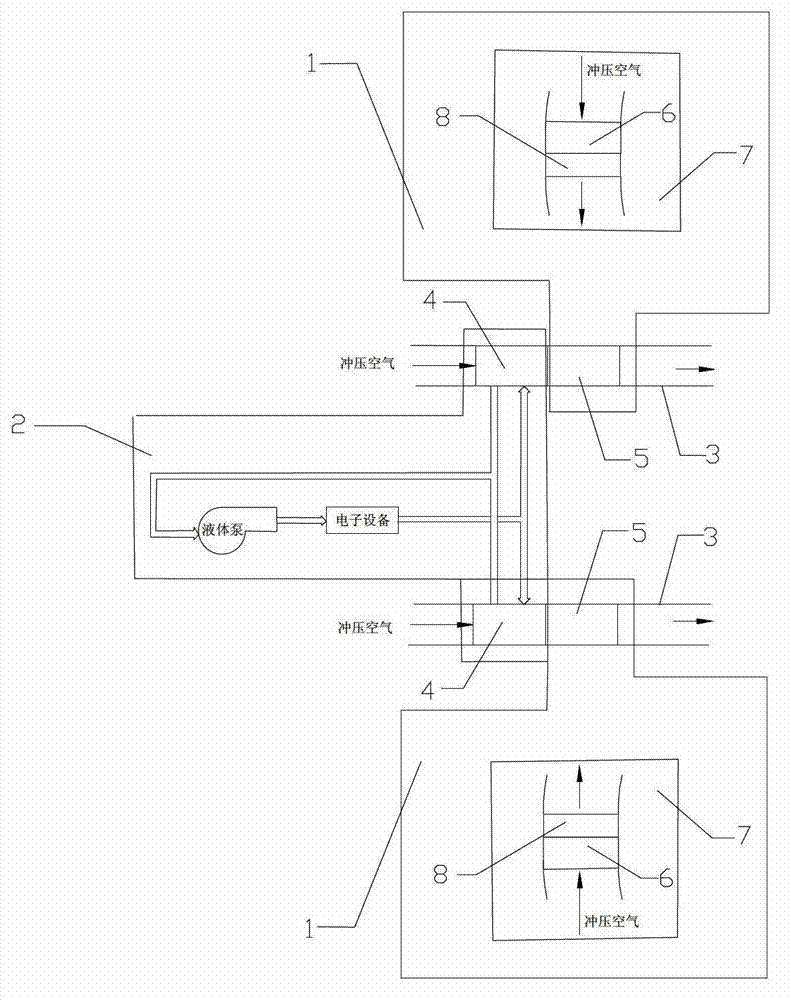

[0022] Reference attached figure 2 , on the basis of Embodiment 1, the air-liquid heat exchanger 4 of the liquid cooling system 1 and the secondary heat exchanger 5 of the environmental control system 2 share a ram air inlet 3, and the rear part of the ram air inlet 3 is divided into two The secondary heat exchangers 5 of the two environmental control systems are respectively installed in the two channels, and the ram air intake 3 is arranged on the top or bottom of the fuselage.

Embodiment 3

[0024] Reference attached figure 2 , on the basis of Embodiment 1, the air-liquid heat exchanger 4 of the liquid cooling system 1 and the secondary heat exchanger 5 of the environmental control system 2 share two ram air inlets 3, and the ram air inlets 3 are symmetrically arranged in on both sides of the fuselage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com