Comprehensive environmental control/liquid cooling heat energy management system without ramjet inlet

A management system, cold and heat energy technology, applied in the direction of air handling equipment, energy-saving board measures, aircraft parts, etc., can solve the problem of insufficient utilization of refrigeration system refrigeration capacity, increase of compensatory loss of refrigeration system performance, reduction of aircraft fuel and flight performance, etc. problems, to achieve the effect of improving water removal and cooling efficiency, reducing performance compensation loss, and improving aircraft fuel efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below by means of specific embodiments:

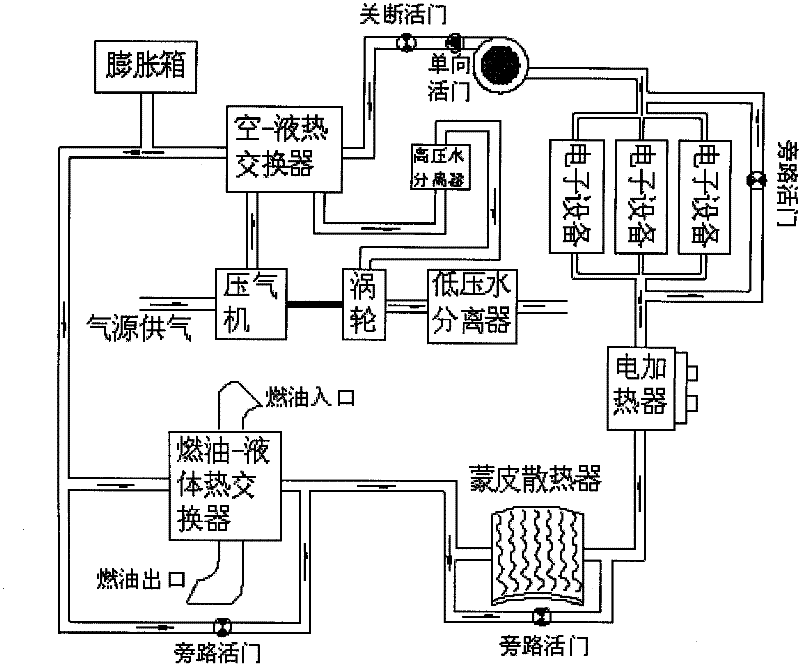

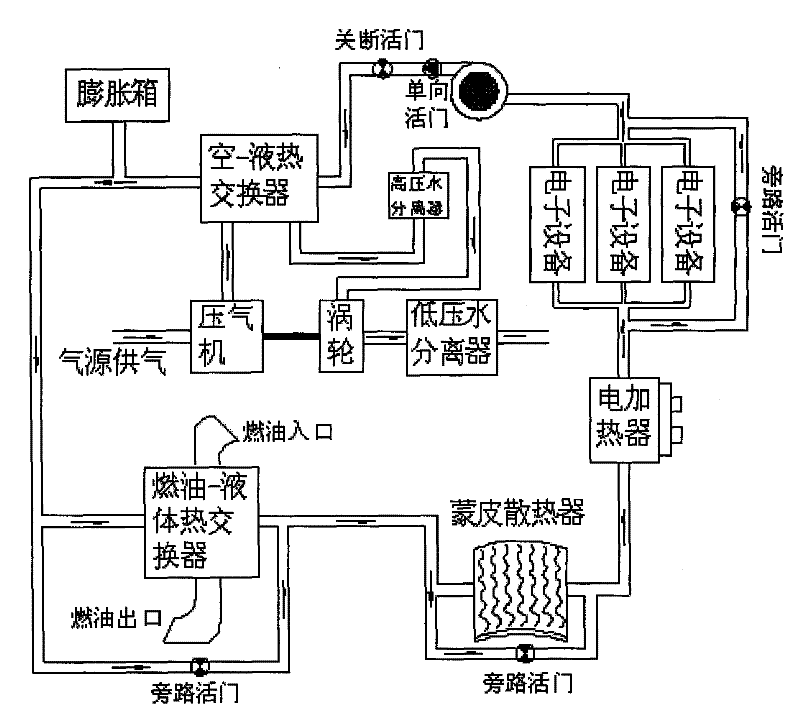

[0019] In the actual working process of the comprehensive environmental control / liquid-cooled thermal management system without ram inlet, the high-pressure and high-temperature air from the air source system is first compressed by the compressor to increase the temperature and pressure, and then cooled by the air-liquid heat exchanger. The free water is separated through the high-pressure water separator, and then the turbine expands and cools down to a lower temperature, and then the free water in the air is further separated through the low-pressure water separator. The outlet air temperature can generally reach -10°C or even lower; liquid cooling The system overcomes the flow resistance through the liquid pump, passes through the one-way valve and the shut-off valve in turn, then passes through the air-liquid heat exchanger to absorb the compression heat of the compressor to inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com