VVT engine oil gallery

A lubricating oil circuit and engine technology, applied in the lubrication of valve accessories, closed-circuit lubrication systems, etc., can solve the problems of complex structure, high cost, heavy weight, etc., and achieve the effect of reducing processing procedures, low cost, and reducing engine weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

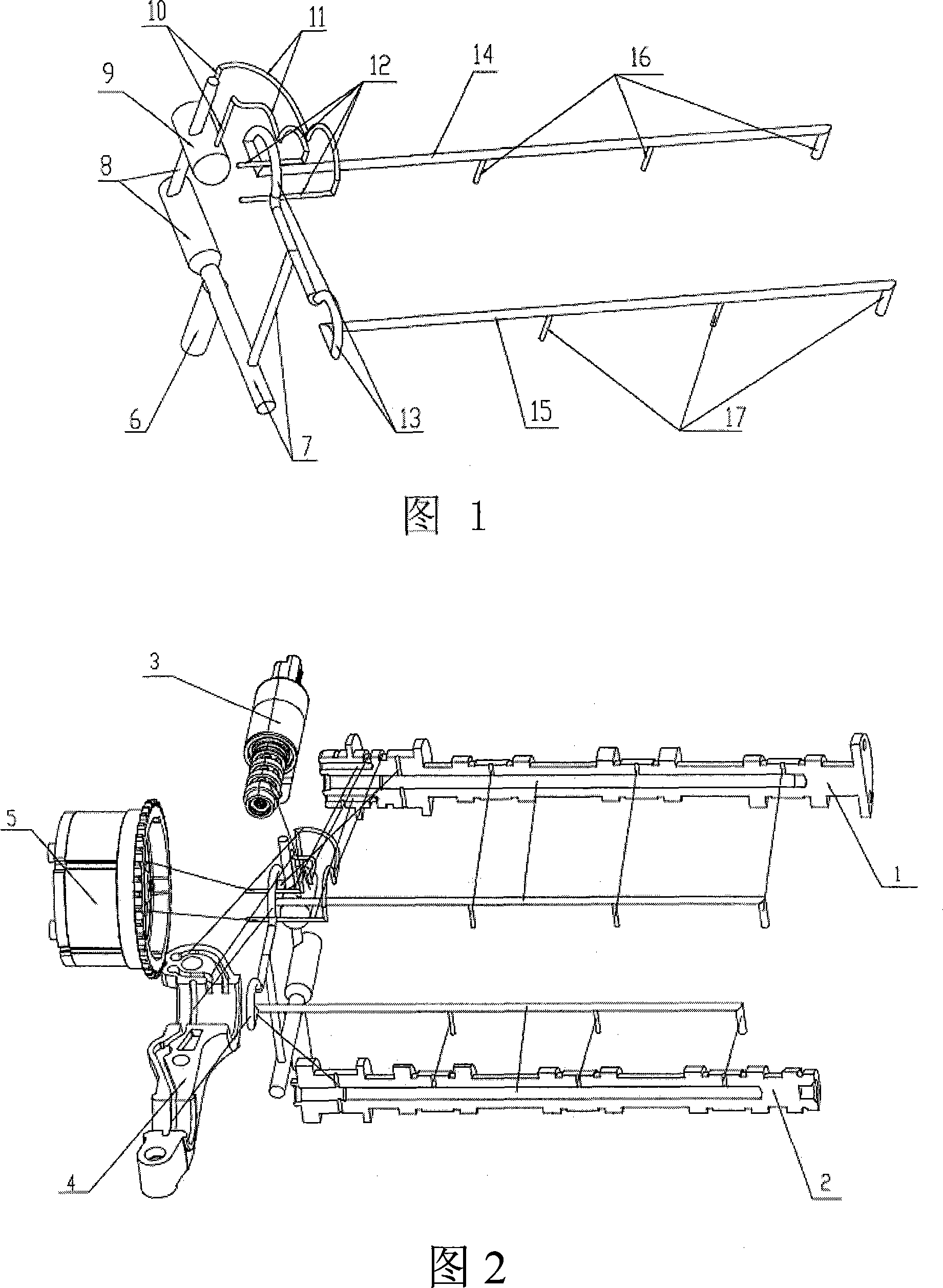

[0020] The present invention will be further described below in conjunction with accompanying drawing:

[0021] As shown in Figure 1 and Figure 2, the cylinder head is provided with a main oil passage 6 connected with the cylinder body. The main oil passage is the bolt hole of the cylinder head. In order to ensure a certain amount of oil in the oil passage, the bolt hole is The bolt hole diameter is 1-1.5mm larger.

[0022] The cylinder head is also provided with the first auxiliary oil passage 8 of the cylinder head and the vertical oil passage 10 of the cylinder head. Road 11 is connected with each other, and the direction of the oil passage is in turn the main oil passage 6, the first auxiliary oil passage 8 of the cylinder head, the oil passage 9 of the phase solenoid valve 3, the vertical oil passage 10 of the cylinder head, the auxiliary oil passage 11 of the bearing cap, the intake air passage Camshaft auxiliary oil passage 12, camshaft phaser 5, this oil passage is oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com