Waste heat collecting system having expansion device

a technology of expansion device and heat collection system, which is applied in the direction of engine components, mechanical equipment, machines/engines, etc., can solve the problems of reducing the output of the expansion device, unable to obtain the necessary amount of work volume, and generating losses by such over expansion, etc., to achieve the effect of increasing the complexity of the expansion device and increasing the cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

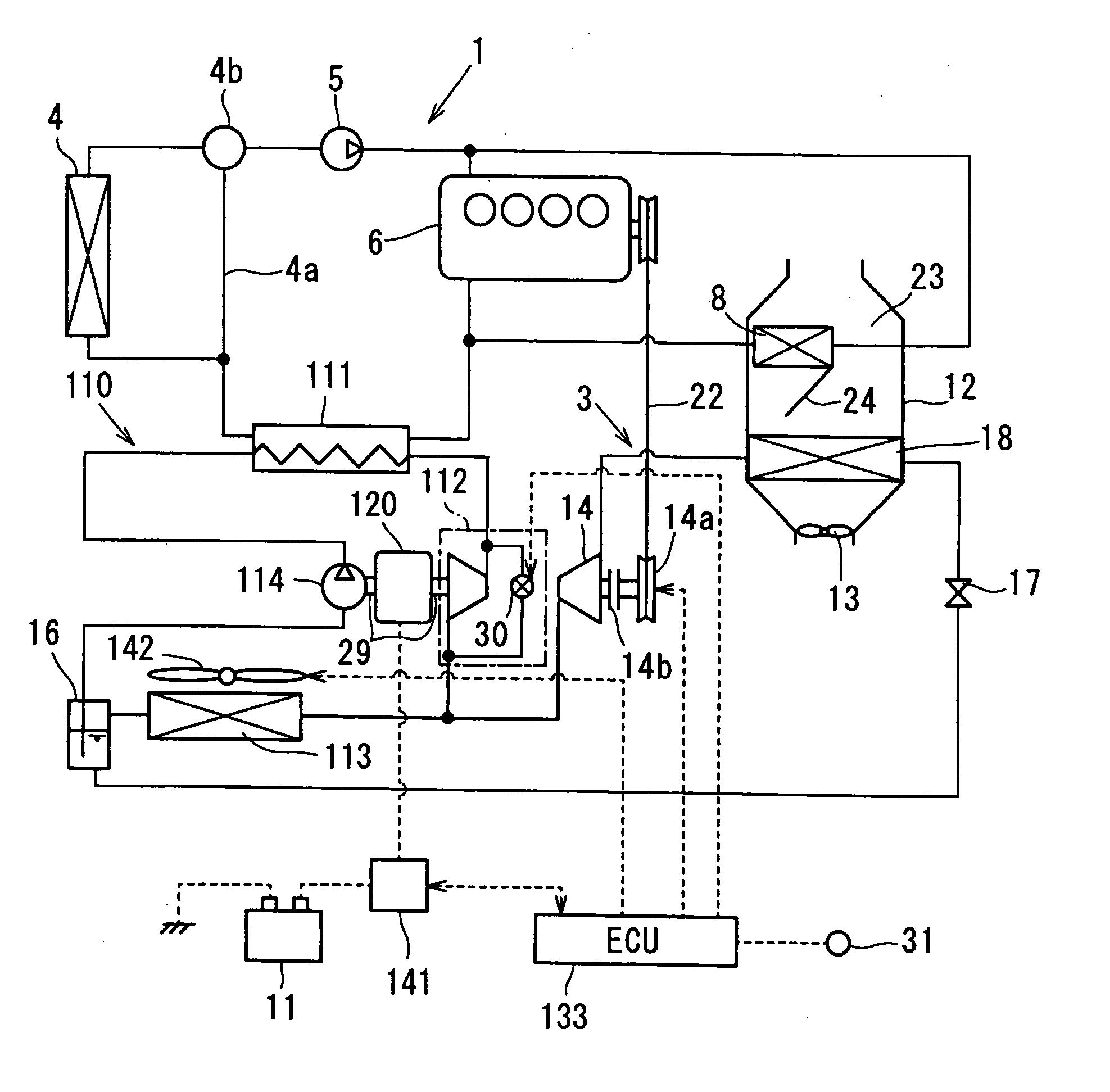

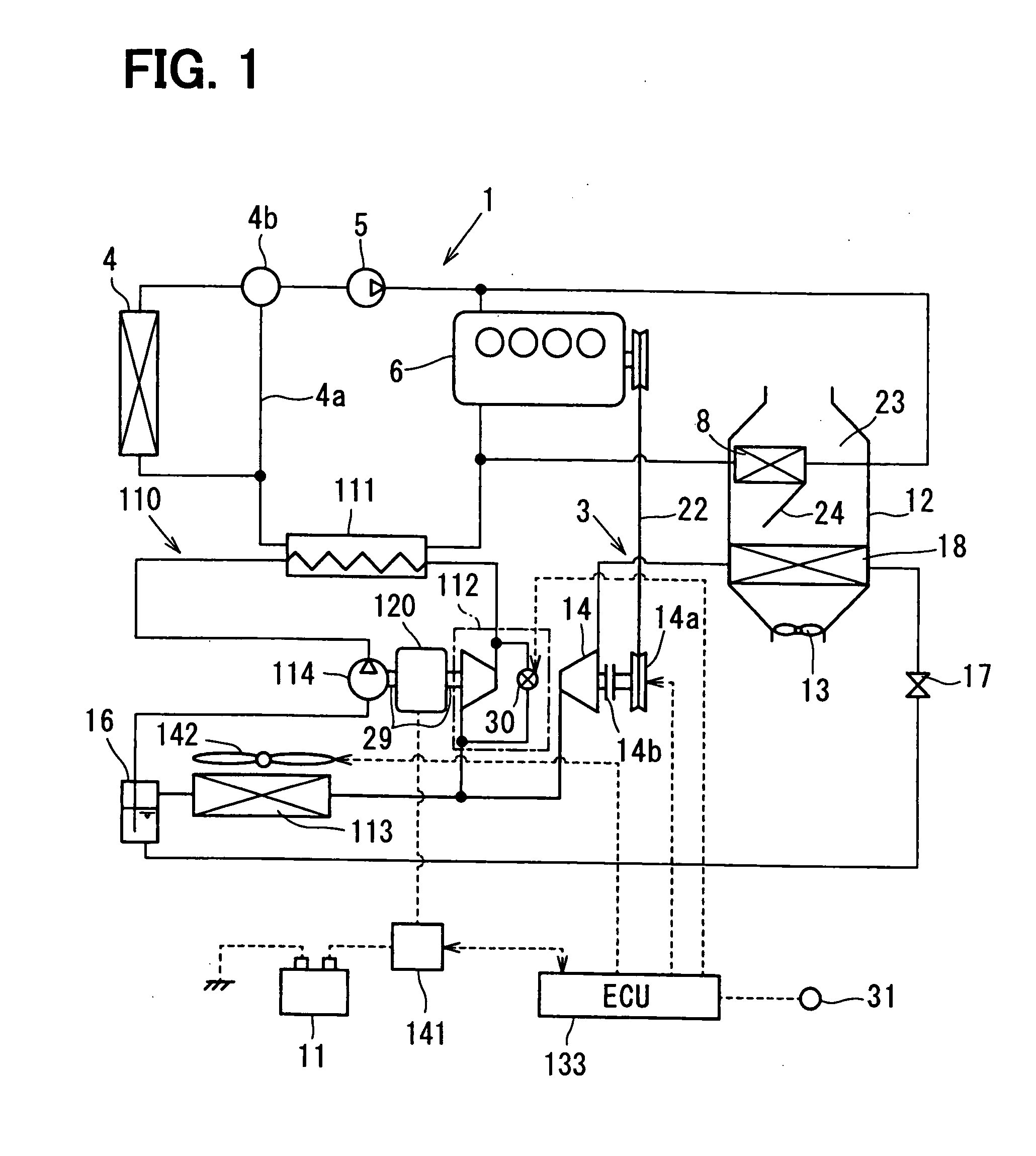

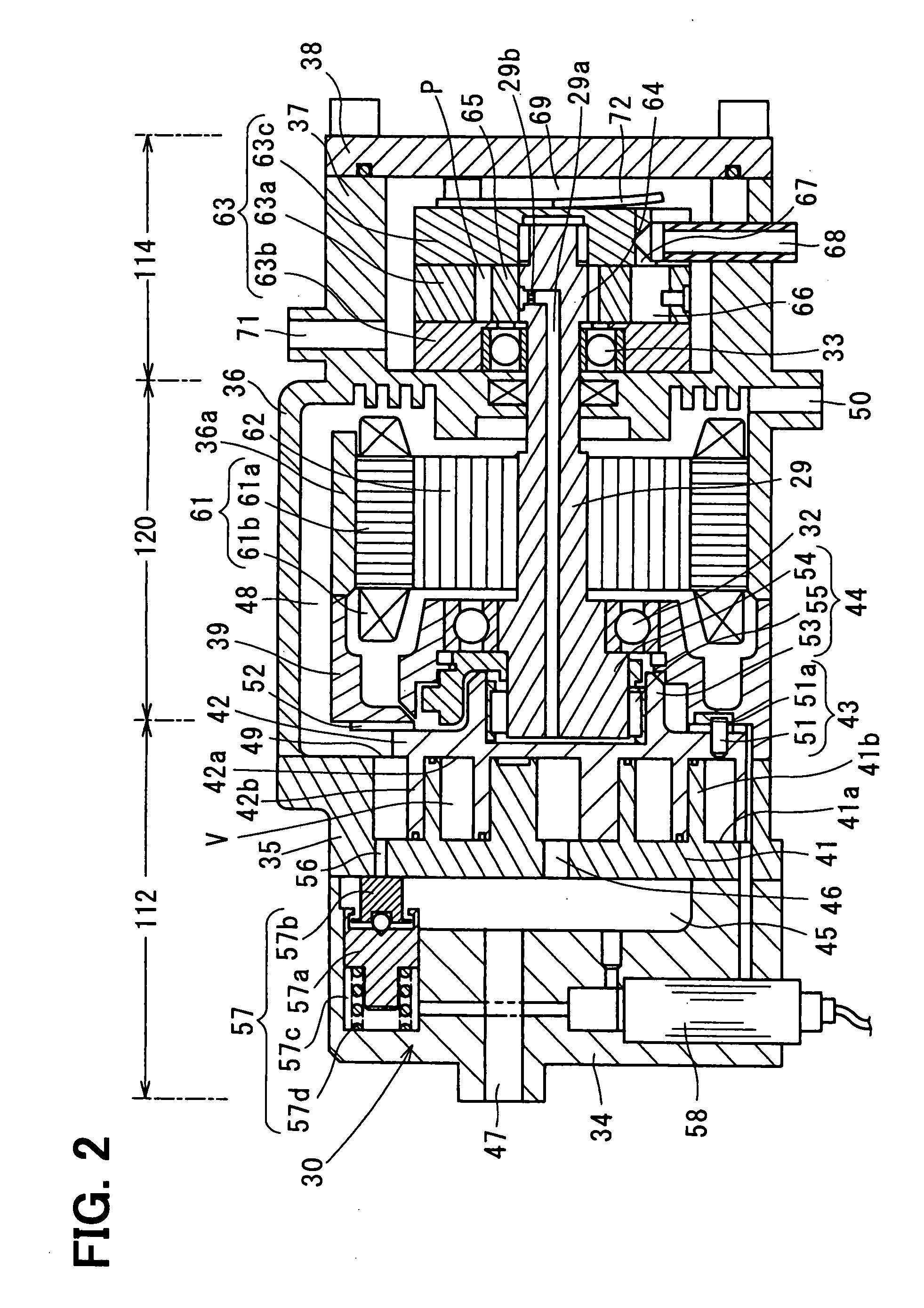

[0042] A system structure of a waste heat collecting apparatus will be explained with reference to FIG. 1. The waste heat collecting apparatus according to an embodiment of the present invention gets a rotational energy, by use of Rankine cycle 110, out of heat in engine cooling water (hot water) circulated in an engine cooling circuit 1, to generate electric power. As shown in FIG. 1, a part of the Rankine cycle 110 is commonly used in a refrigerating cycle 3 for an air conditioning apparatus mounted in an automotive vehicle.

[0043] The engine cooling circuit 1 has a main circuit, in which the engine cooling water is circulated from a radiator 4, a water pump 5, an engine (a water jacket), a heating device 111, and back to the radiator 4. The engine cooling circuit 1 has an air conditioning hot water circuit, in which the engine cooling water (hot water) is circulated from the engine (the water jacket), a heater core 8, and back to the engine. The heating device 111 is a component ...

second embodiment

[0150] A second embodiment of the present invention will be explained with reference to FIGS. 6 and 7. A structure will be explained with reference to FIG. 6. The second embodiment shows a control system for an expansion device, which is applied to an expansion device 112 to be used in Rankine cycle 110 to be mounted in an automotive vehicle.

[0151] The vehicle, to which the present invention is applied, is a general passenger car, which is equipped with a water-cooled internal combustion engine (not shown) as a driving source for a vehicle travel. An alternator 150 is mounted in the vehicle, which is driven by the engine to generate electric power. The electric power generated by the alternator 150 is charged into a battery 11 through an inverter 141, and the electric power charged in the battery 11 is supplied to vehicle electrical loads 160, such as head lamps, a wiper motor, an audio equipment, and so on.

[0152] The Rankine cycle 110 collects waste heat (thermal energy of engine...

third embodiment

[0174] A third embodiment of the present invention is shown in FIGS. 8 and 9. In the third embodiment, the condensing device 113 and the blower device 142 are formed as the means 140A for increasing the pressure difference ΔP. The same reference numerals are used in the third embodiment to designate the same or similar components and parts in the third embodiment.

[0175] The blower device 142 of the third embodiment is formed as an electrical blower device for blowing the cooling air to the condensing device 113, as shown in FIG. 8. A rotational speed of the electrical blower device 142 is controlled by the controller 133. An operation of the third embodiment will be controlled by a flow chart shown in FIG. 9. In FIG. 9, the steps S120 and S130 of FIG. 7 are replaced by steps of S120A and S130A.

[0176] When the controller 133 determines, at the step S110, that the pressure difference ΔP at the expansion device 112 is lower than the predetermined pressure difference ΔPth, the control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com