Lossless single crystal wafer with edges convenient to identify, and marking method thereof, and special grinding wheel

A marking method and single-wafer technology, applied in the direction of bonded grinding wheel, laser welding equipment, electrical components, etc., can solve the problems of low processing efficiency, reduce processing damage rate, avoid axial processing, and increase the effect of effective use area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

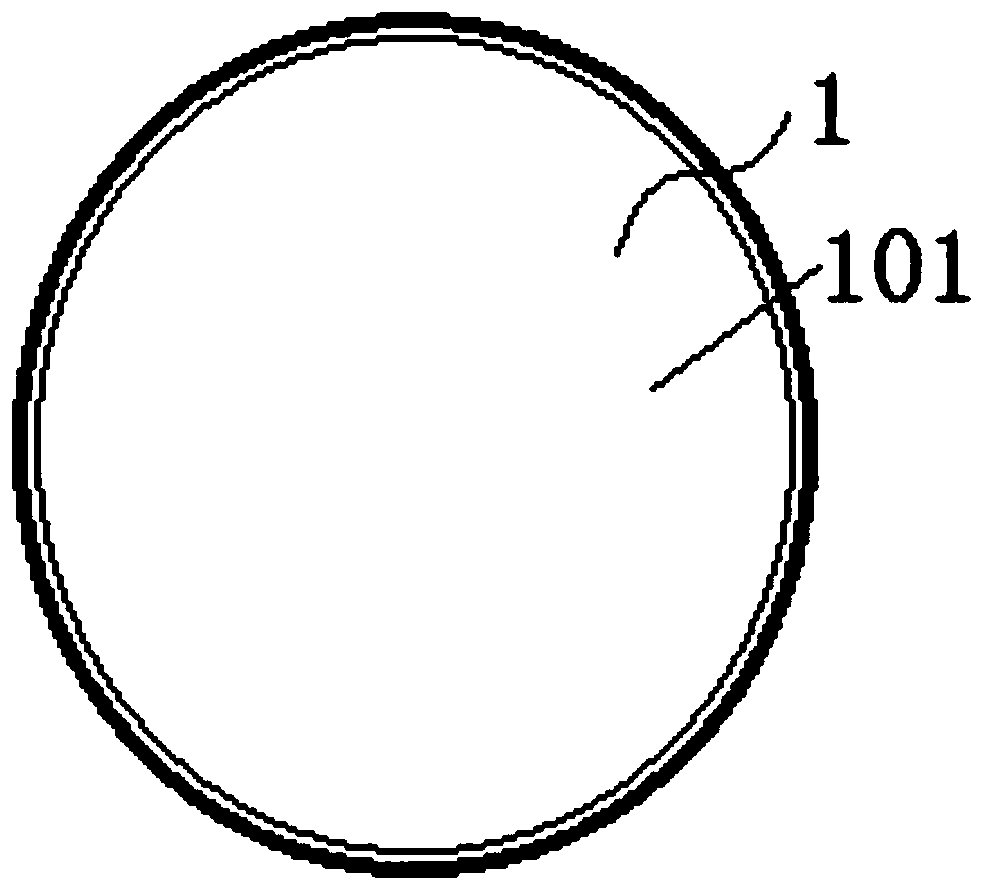

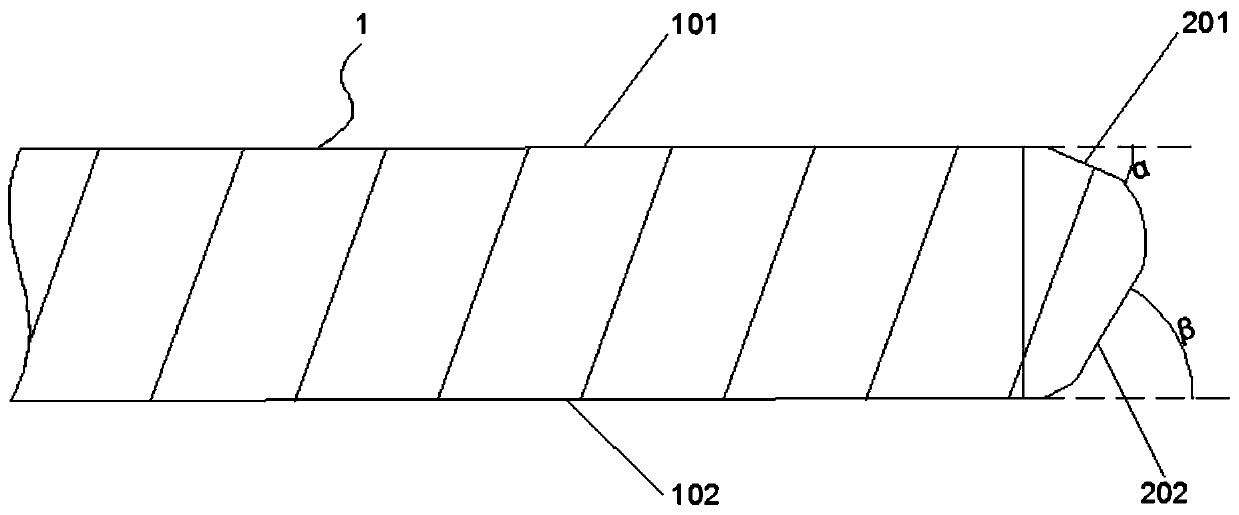

[0025] Such as Figure 1 to Figure 3 As shown, the present invention is a non-destructive single wafer whose edge is easy to identify, including a circular wafer body 1, which includes an upper surface 101 and a lower surface 102, and is processed at the edge of the wafer body 1 for identification. Chamfering 2, the chamfering 2 includes an upper bevel 201 and a lower bevel 202, the upper bevel 201 and the lower bevel 202 are asymmetrically arranged to avoid axial processing of the thinner wafer body 1 and reduce the processing damage rate. The upper bevel The intersection of 201 and upper surface 101 and the intersection of lower slope 202 and lower surface 102 are located on the same axis, so that the diameters of upper slope 201 and upper surface 101 are the same, which can increase the effective area of wafer body 1 . Adjacent positions of the upper bevel 201 and the lower bevel 202 are connected by an outwardly protruding arc-shaped fillet, and this edge treatment metho...

Embodiment 2

[0028] On the basis of Embodiment 1, this embodiment is introduced by taking the wafer body 1 as an example of a silicon single crystal material.

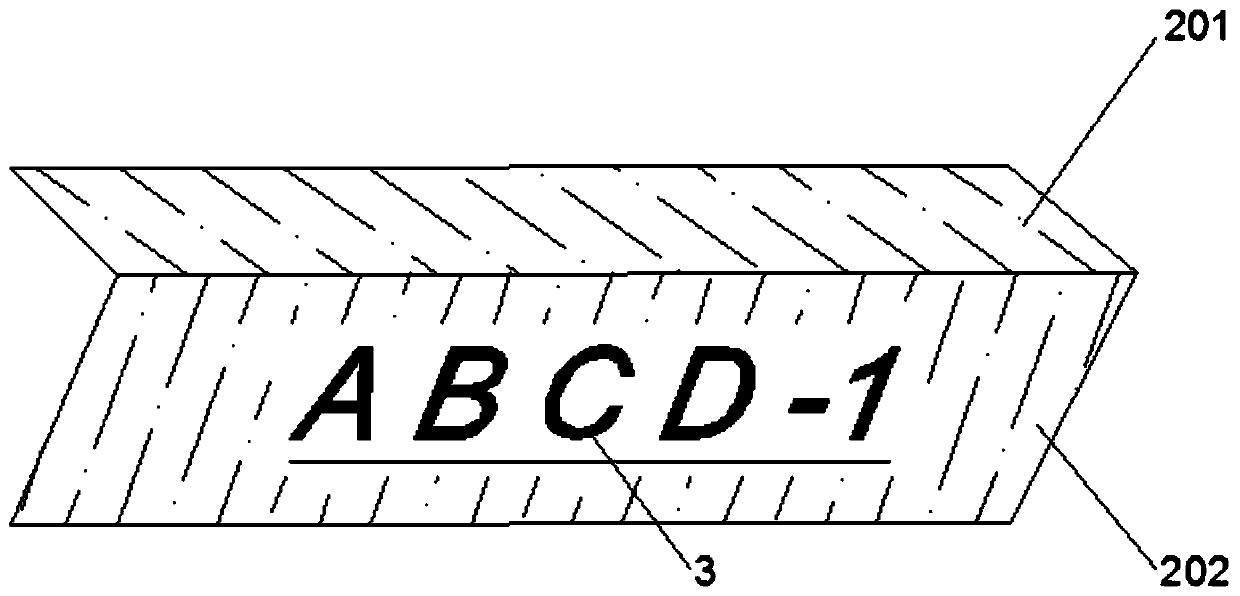

[0029] The wafer body 1 can be used as a substrate wafer, the upper surface 101 is a front surface, and the lower surface 102 is a back surface. When the wafer body 1 is used as a substrate wafer, it is necessary to engrave an identifier 3 on the lower surface 102 with a laser, and the identifier 3 includes the direction of the crystal plane, the crystal orientation here, such as .

Embodiment 3

[0031] On the basis of Embodiment 1, this embodiment is introduced by taking the wafer body 1 as an example of silicon carbide single crystal material.

[0032] The wafer body 1 can be used as a wafer for a substrate or a wafer for a seed crystal, the upper surface 101 is a carbon plane (i.e. C plane, 000-1 plane), and the lower surface 102 is a silicon plane (i.e. Si plane, 0001 side). When the wafer body 1 is used as a substrate wafer, it is necessary to engrave an identifier 3 with a laser on the lower surface 102, and the identifier 3 includes a crystal plane direction, and the crystal orientation at this place, such as ; when the wafer body 1 When used as a wafer for a seed crystal, it is necessary to engrave an identifier 3 on the lower surface 102 with a laser, and the identifier 3 includes a crystal plane direction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com