Processing technology of apricot kernel oil

A processing technology, almond oil technology, applied in the direction of fat oil/fat production, fat oil/fat refining, fat production, etc., can solve the problems affecting the quality of extracted almond oil, low oil yield, solvent residue, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

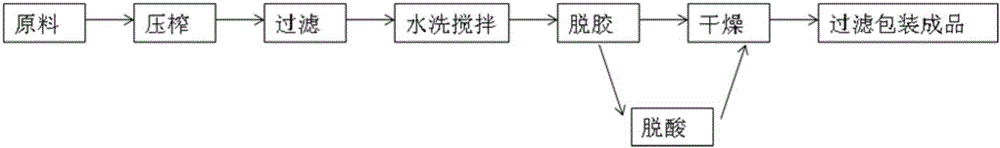

Method used

Image

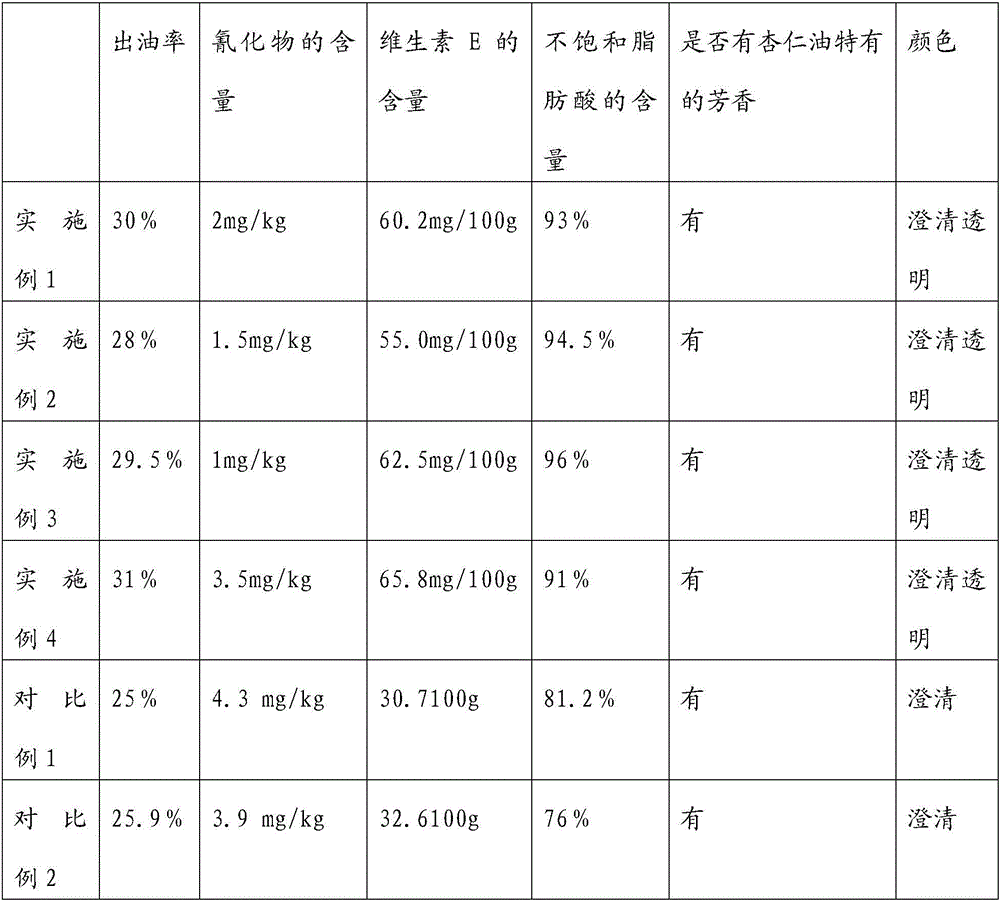

Examples

Embodiment 1

[0070] 1) select debittered almonds as raw materials, and perform physical pressing to obtain crude oil and oil cake;

[0071] When the debittered almonds are used as raw materials, the debittered almonds can be prepared by the following method: soak in an aqueous solution at 90°C for 5 minutes, perform peeling treatment, and debitterize the almonds by alternately soaking in warm water at 30°C every four hours. Four times, dehydration, drying at 60°C for 8 hours, cooling, color sorting, and packaging to obtain debitter almonds. The color of the prepared debittered almonds is milky white or off-white, slightly glossy, free from mildew, free from insects, uniform particle shape, no obvious abnormal particles, with the proper aroma and taste of almonds, no peculiar smell, no visible to the naked eye Foreign impurities whose moisture content is less than 10%.

[0072] Water should meet the requirements of GB-5749.

[0073] When pressing, use physical pressing method to avoid sol...

Embodiment 2

[0096] 1) Select sweet almonds as raw materials and perform physical pressing to obtain crude oil and oil cakes;

[0097] Sweet almonds: should comply with the provisions of GB / T 20452. It is required that the sweet almonds have normal color, no mildew, no insects, uniform particle shape, no obvious abnormal particles, have the proper aroma and taste of sweet almonds, no peculiar smell, no visible foreign impurities, moisture less than 10%, raw materials are Selected sweet almonds.

[0098] Water should meet the requirements of GB-5749.

[0099] When pressing, use physical pressing method to avoid solvent residue and high soap content. The specific operation is:

[0100] Put 5kg of raw material into the press bag, put it into the steel drum of the hydraulic press, seal the steel drum, and prepare for pressing. When the pressure reaches about 10MPa, the oil discharge starts. When the pressure reaches 55Mpa, the oil discharge basically ends. The oil is basically over. Durin...

Embodiment 3

[0122] 1) select debittered almonds as raw materials, and perform physical pressing to obtain crude oil and oil cake;

[0123] When debittering almonds are used as raw materials, the debittering almonds can be prepared by the following method: soak in an aqueous solution at 92°C for 8 minutes, perform peeling treatment, and debitterize by alternately soaking in warm water at 40°C every four hours with hot and cold water, alternately Four times, dehydration, drying at 65°C for 9 hours, cooling, color sorting, and packaging to obtain debitter almonds. The color of the prepared debittered almonds is milky white or off-white, slightly glossy, free from mildew, free from insects, uniform particle shape, no obvious abnormal particles, with the proper aroma and taste of almonds, no peculiar smell, no visible to the naked eye Foreign impurities whose moisture content is less than 10%.

[0124] Water should meet the requirements of GB-5749.

[0125] When pressing, use physical pressi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com