Method for preparing ultra high-purity alcohol compound

A compound and alcohol technology, applied in the field of alcohol compound purification, can solve the problems of decreased resin exchange effect, unfavorable influence on production efficiency, etc., and achieve the effects of low price, convenient preparation, simple and easy equipment combination and operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

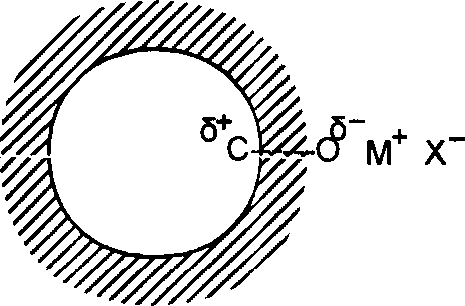

Method used

Image

Examples

Embodiment 1

[0029] Add 200 grams of activated carbon for surface oxidation into an adsorption column with a diameter of 50 mm and a length of about 600 mm. At room temperature (about 24 ° C), slowly add 5000 mL of distilled industrial methanol with a content of 99.9%. When the liquid starts to flow out, collect the effluent , Control the outflow rate to be 5ml / min / 100g activated carbon. When the collection is complete, recirculate the adsorption once, and finally collect 4855mL of purified liquid, with a single treatment yield of 97.10%. The results of index analysis before and after treatment are as follows:

[0030] Chemical indicators

Embodiment 2

[0032] Chemical indicators

Embodiment 3

[0034] Chemical indicators

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com