Continuous producing technique for ultra-high pure nitric acid

A pure nitric acid and process technology, applied in the technological field of continuous production of ultra-high-purity nitric acid, can solve the problems of difficult removal of impurities, impurity content cannot reach ultra-pure nitric acid, etc., and achieves low production cost, low impurity ion content, and high product purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

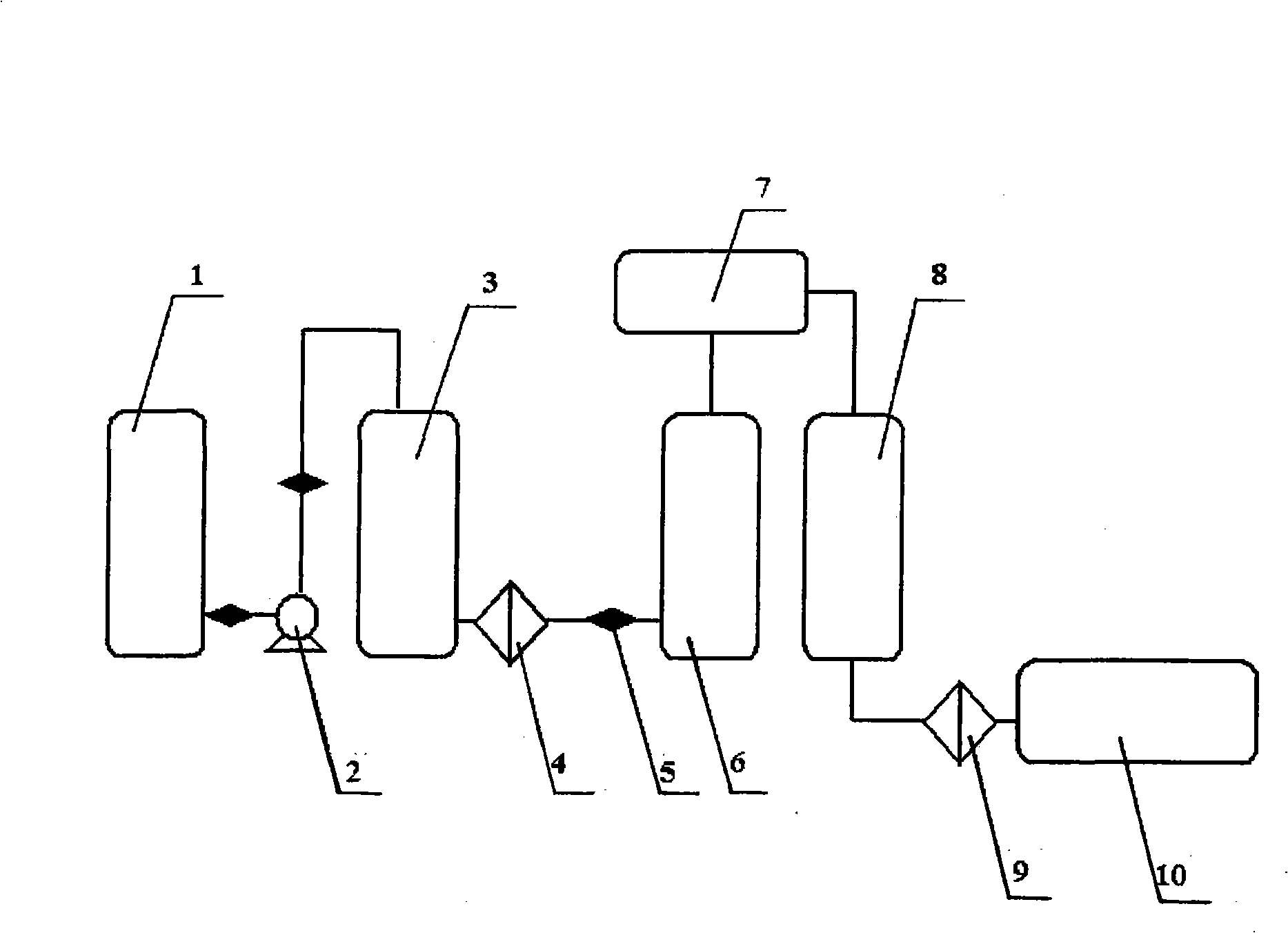

[0011] The technique of the continuous production of ultra-high-purity nitric acid of the present invention is as follows (see figure 1 ): first the industrial grade nitric acid (98%) raw material is mixed with the organosilicon polymer complexing agent that accounts for 0.5%~1% of nitric acid raw material weight 18-crown-6 ether in the preconditioner, Then filter through the microfiltration membrane in the microfilter under the operating pressure of 0.15MPa, and the filtrate enters the rectification tower, and the semi-finished product exiting the rectification tower is diluted with 18MΩ·cm ultrapure water in the dilution device, and is ready to be diluted After the end, use high-purity nitrogen to drive off free NO in the white blowing device 2 , the resulting semi-finished product enters the finished product receiver after being filtered by the nanofiltration membrane in the nanofilter under the operating pressure of 0.6MPa. In the present embodiment, the pressure selectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com