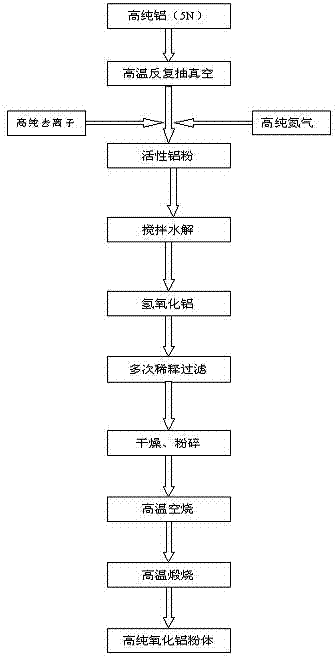

Method for preparing micron-sized ultra-high-purity aluminum oxide powder by virtue of full-process regulation control

A micron-sized alumina powder technology, which is applied in the field of micron-sized ultra-high-purity alumina powder prepared by the whole process control, can solve the problems of long production cycle, high cost, and many process links, and achieve easy industrial production and operation Convenience and wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

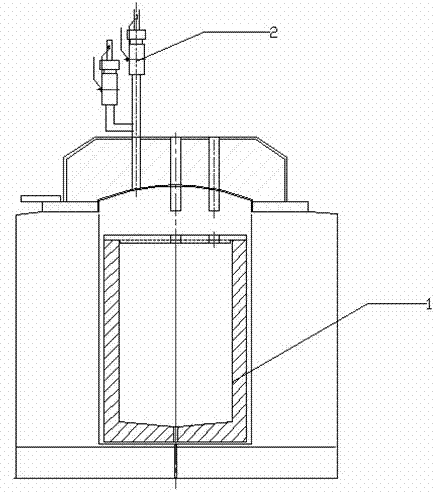

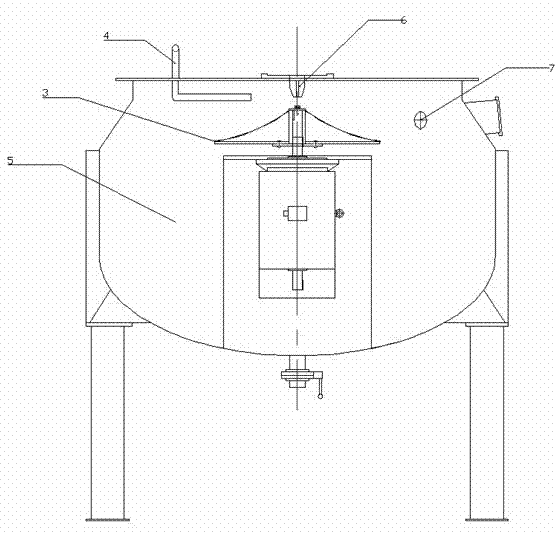

[0029] The preparation method of high-purity alumina according to the present invention uses high-purity aluminum as raw material, puts the pretreated high-purity aluminum ingot into the high-purity graphite crucible 1 of the melting furnace, heats up the melting furnace to 1150° C., and Nitrogen or evacuated pipeline 2 is fed with nitrogen, then evacuated, repeated 5 times, then cooled to 950°C for heat preservation, and the centrifugal pure aluminum turntable 3 is turned on at a high speed at 6000 rpm, and the atomization chamber 5 is opened to remove Ionized water spray device 4, and then continue to open the nitrogen generator through the pipeline 7 of the quenching atomization atmosphere to fill the atomization chamber 5 with high-purity nitrogen pressure up to 3.0MPa; after the high-speed rotating turntable, high-purity cooling water, and high-purity nitrogen stabilize , forming high-temperature aluminum droplets by the ultrasonic pneumatic atomizer 6, releasing the a...

Embodiment 2

[0031] The preparation method of high-purity alumina according to the present invention uses high-purity aluminum as raw material, puts the pretreated high-purity aluminum ingot into the high-purity graphite crucible 1 of the melting furnace, heats up the melting furnace to 1150° C., and Nitrogen gas or the vacuumed pipeline 2 is flushed with nitrogen gas, then vacuumed, repeated 3 times, then cooled to 950°C for heat preservation, and the centrifugal pure aluminum turntable 3 is turned on at a high speed of 4000 rpm, and the atomization chamber 5 is opened to remove Ionized water spray device 4, and then continue to open the nitrogen generator through the pipeline 7 of the quenching atomization atmosphere to fill the atomization chamber 5 with high-purity nitrogen pressure up to 3.5MPa; after the high-speed turntable, high-purity cooling water, and high-purity nitrogen are stabilized, The high-temperature aluminum droplets are formed by the ultrasonic pneumatic atomizer 6,...

Embodiment 3

[0033]The preparation method of high-purity alumina according to the present invention uses high-purity aluminum as raw material, puts the pretreated high-purity aluminum ingot into the high-purity graphite crucible 1 of the melting furnace, heats up the melting furnace to 1150° C., and Nitrogen or vacuumed pipeline 2 is flushed with nitrogen gas, then vacuumed, repeated 3 times, then cooled to 950°C for heat preservation, and the centrifugal pure aluminum turntable 3 is turned on at a high speed at 3000 rpm, and the atomization chamber 5 is opened to discharge Ionized water spray device 4, then continue to open the nitrogen generator through the pipeline 7 of the quenching atomization atmosphere to fill the atomization chamber 5 with high-purity nitrogen pressure up to 4.0MPa; after the turntable, high-purity cooling water, and high-purity nitrogen are stable, the Ultrasonic pneumatic atomizer 6 forms high-temperature aluminum droplets, releases aluminum liquid into atomizatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com