Crane cable for high-building

A high-rise building and cable technology, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems that the tensile strength cannot meet the requirements of vertical hanging laying, cable stability, adverse effects on reliability, small contact area and friction force, etc. , to reduce hanging and construction costs, increase the overall tensile strength, and reduce the side pressure of the cable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

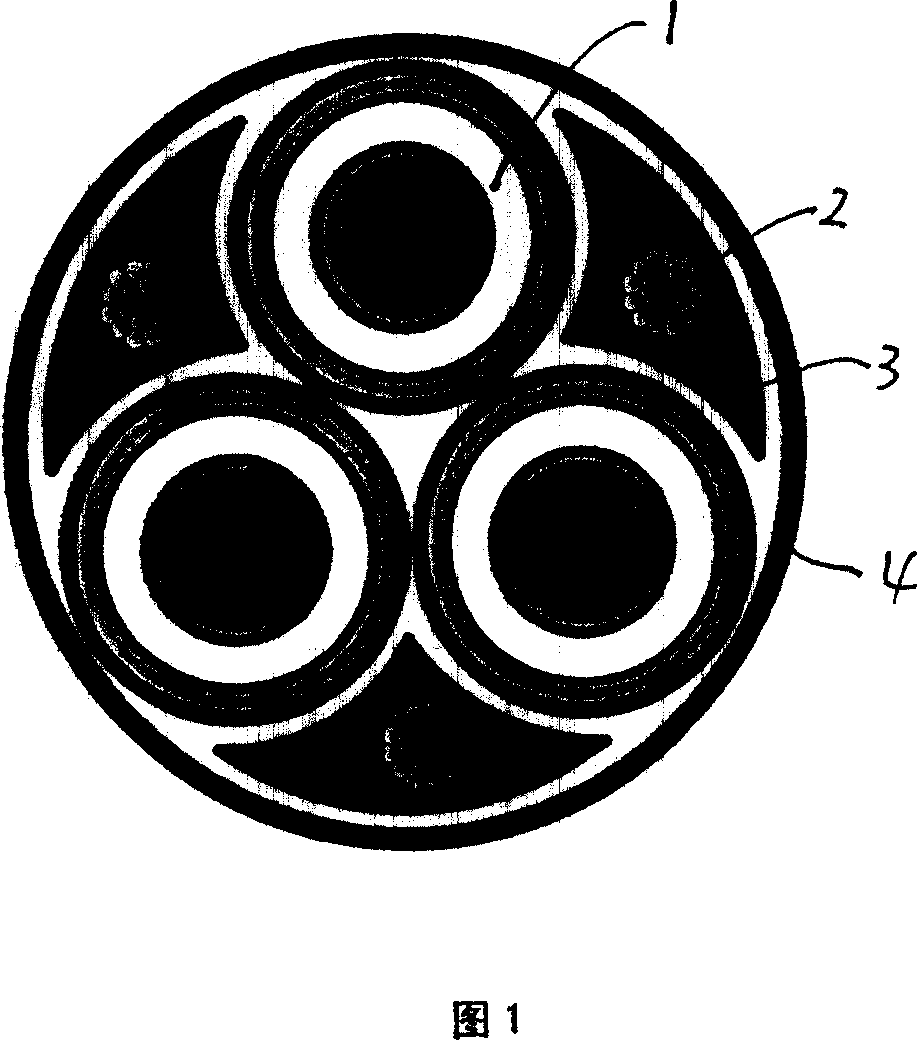

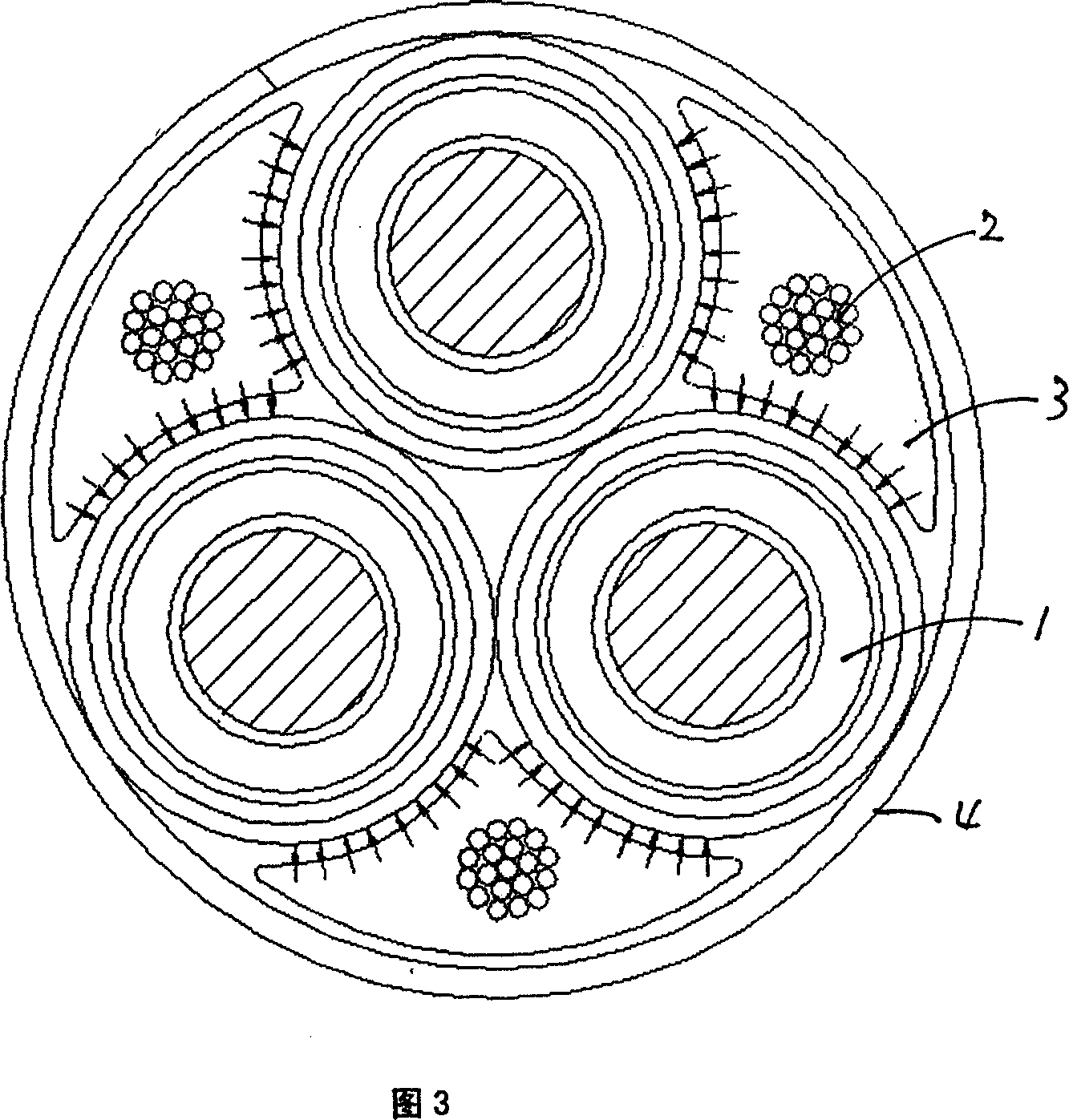

[0017] Embodiment 1: Referring to the accompanying drawings, the hoisting cable for high-rise buildings of the present invention has three single-core insulated cables 1 arranged in a triangle, and three cables are arranged longitudinally between the cables, and the cross-section of the load-bearing steel wire rope 2 is an arc fan-shaped insulation 3. The insulated load-bearing steel ropes are jointly twisted into a cable, and the cable ties 4 for external steel wire rope insulation are bundled and tightened.

[0018] In addition, a conductor shield and an insulation shield can be respectively provided on the conductor and the insulation of the single-core insulated cable, and a metal shield can also be provided on the outside of the insulation shield.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com