Tie-down rope winding and unwinding device

A technology of retracting and releasing device and mooring rope, applied in the field of floating platform, can solve the problems of reducing the service life of the cable, endangering the safety of the system, protecting the foreskin wear, etc., and achieves the effects of reducing the failure rate, reducing energy consumption and balancing the force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

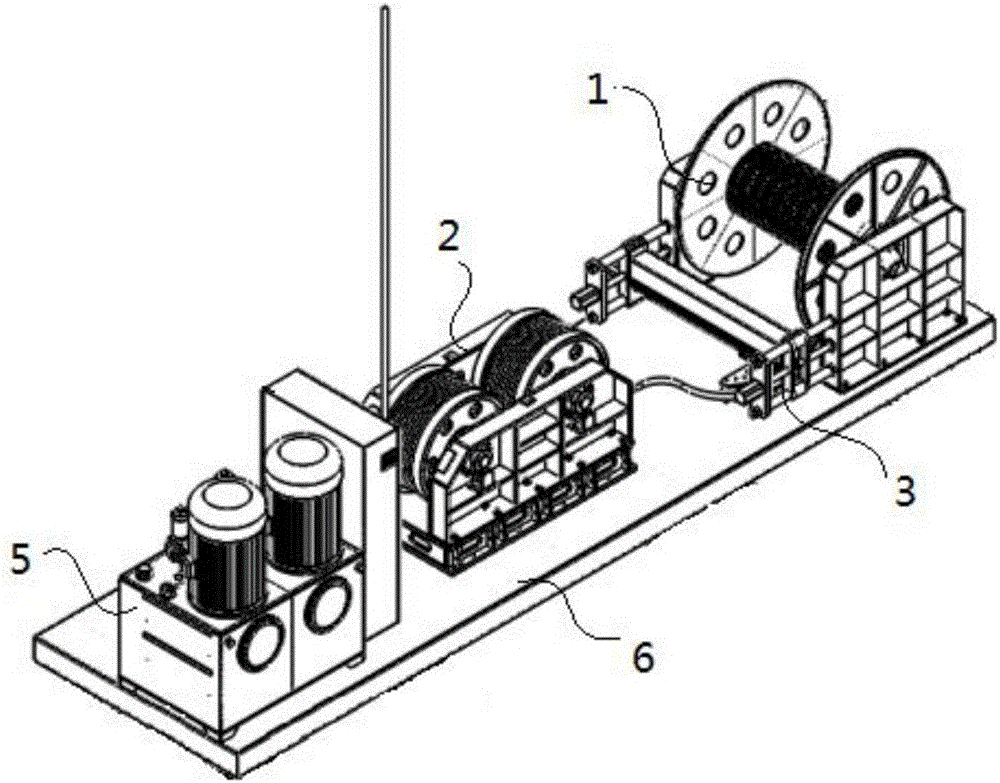

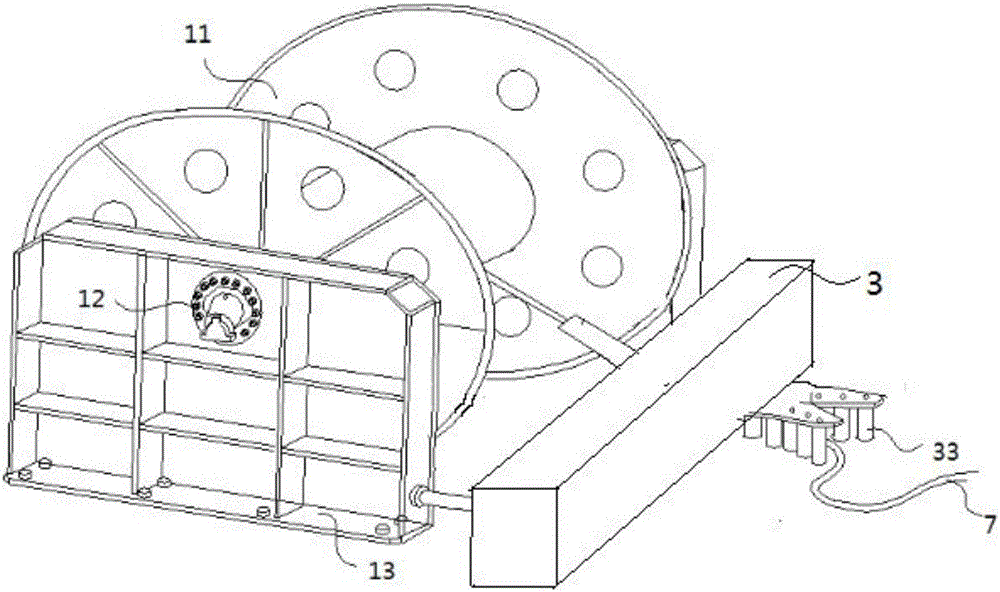

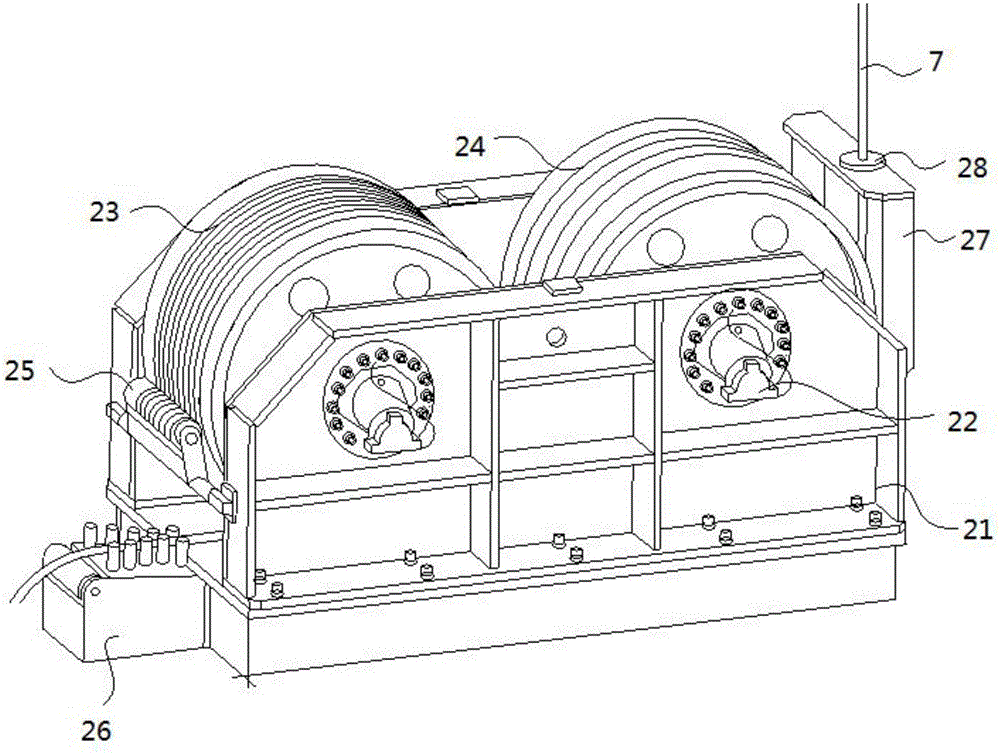

[0037] like Figure 5 As shown, a mooring rope retracting and releasing device in this embodiment is installed on the anchor car 6 in connection with the bottom plate, and can directly obtain the hydraulic source from the construction vehicle to realize power transmission. And the anchor car 6 can be moved to adapt to the adjustment of the position change of the floating platform. In this embodiment, the cable 7 is wound on the traction sheave by a single layer and multiple turns, and after the tension of the lower end of the cable 7 is attenuated, the cable 7 is wound on the take-up drum 11 . When the floating platform is normally released, the traction device 2, the winding device 1 and the cable arrangement 3 are operated to release the cable 7 from the winding drum 11, and the floating platform relies on the buoyancy to pull the cable 7 out. When recovering the balloon, operate the relevant equipment to rotate in the opposite direction, and neatly recover and wrap the cab...

Embodiment 2

[0039] In this embodiment, a mooring rope retracting and releasing device system is provided with manual mode and automatic mode, which can be adjusted according to needs. In this embodiment, all the pipeline connections of the power output adopt quick self-sealing joints, which can be adjusted according to the needs. It is necessary to replace different power sources, which is convenient and safe to replace. In case of emergency, such as power failure, the manual mode can be selected, and the pipeline connected to the hydraulic pump station 5 is connected to the manual oil pump, which can still meet the needs of the floating platform recovery without the need for electricity at all.

Embodiment 3

[0041] Under normal circumstances, the system only needs one main oil pump motor 51 to meet the requirements, but when this embodiment needs to enter the emergency working mode, there is also a spare oil pump motor 52 to be used at this time, and the two motors are running at the same time, which can reach the maximum operation. speed and pulling force, thereby reducing energy consumption.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com