Car or train running system and housing body thereof

A technology for trains and covers, applied in the field of transportation, can solve problems such as the difficulty of increasing the speed of high-speed trains, and achieve the effect of reducing energy consumption and increasing natural speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

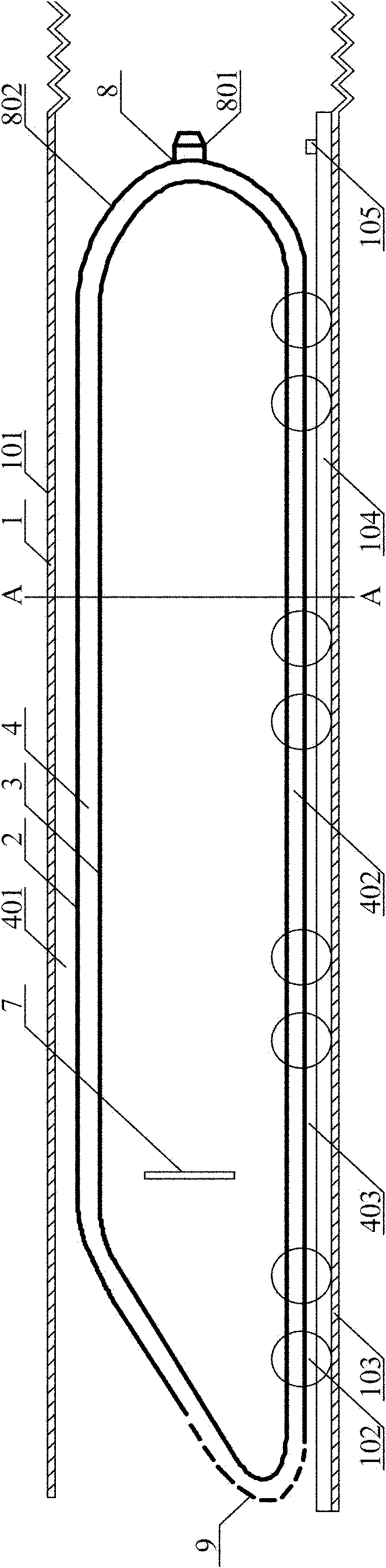

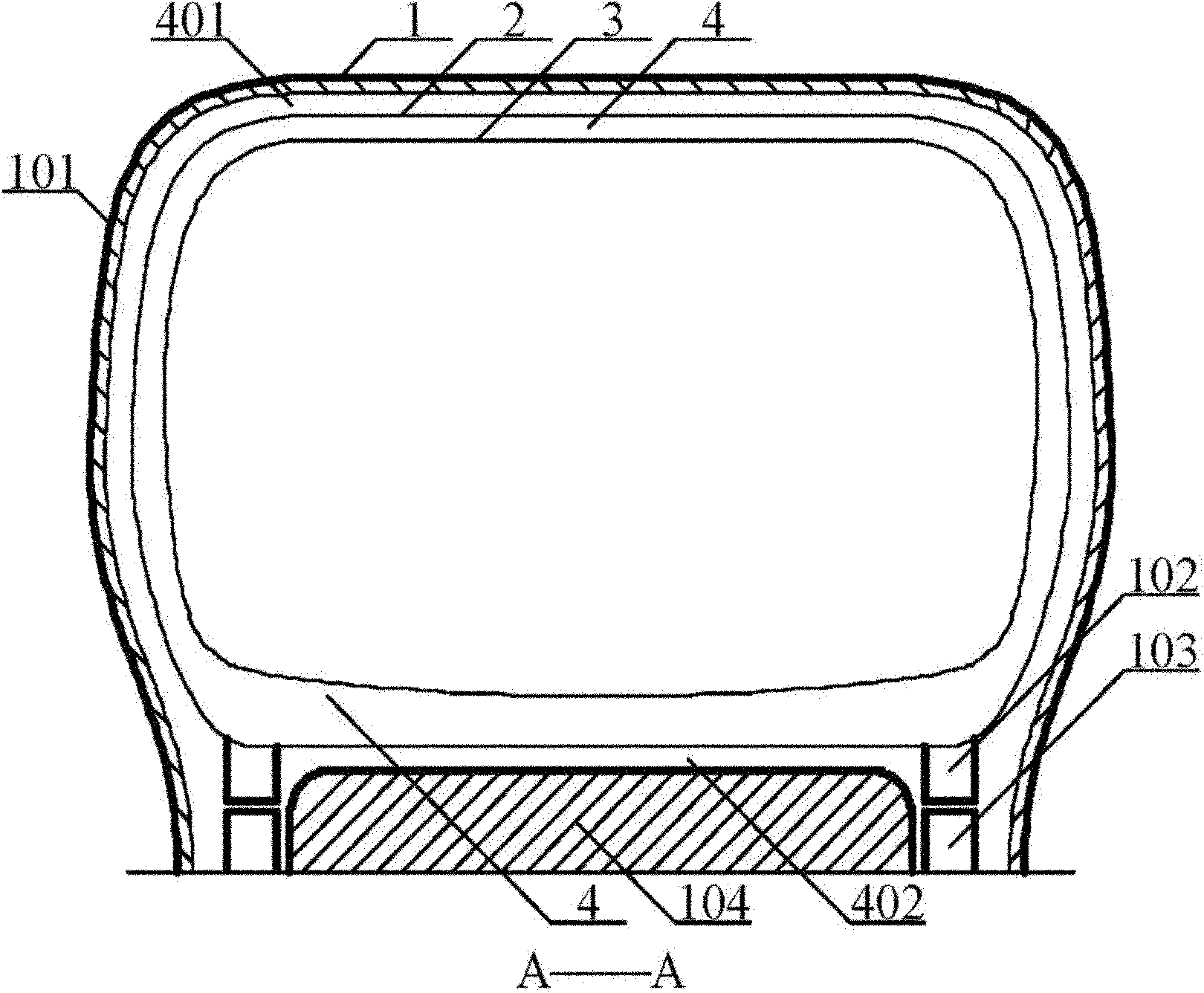

[0055] Example 1, such as Figure 1-2 As shown, the train is closed to run in the cover body 1. The two sides and the top of the cover body shell are covered with solar cells, such as solar energy collection panels 101 (or films), which are converted into electric energy and stored in a plurality of accumulators 105. Thousands of kilometers long The solar collection plate 101 on the cover shell forms a very large-scale solar power plant, which generates enough power to drive the train, and can also output the remaining electric energy. The outside of the window corresponding to the train on both sides of the cover body 1 can be a transparent material, a sufficiently large front inlet 9 at the front of the train with the same width as the housing, and multiple lateral pressure inlets 7 around the surroundings and the annular interior air surrounding the train. Passage 4 communicates with the middle export port 8 at the rear. The guide body 802 is semicircular around the export ...

Embodiment 2

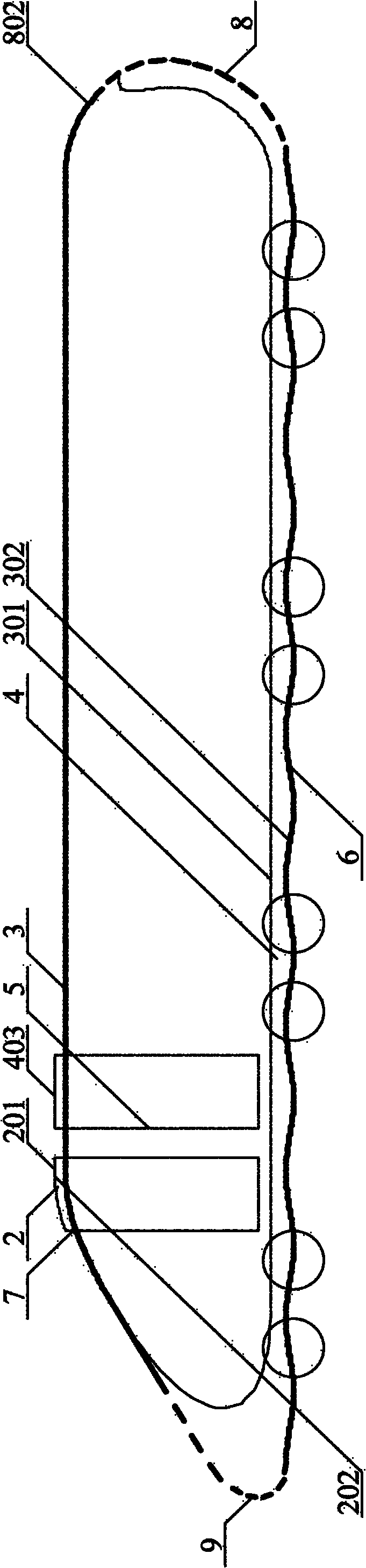

[0059] Example 2, such as image 3 As shown, the difference from Example 1 is that the image 3 Put it in the cover body 1, remove the filling block 104 (not shown), the front end is provided with the front end inlet 9 about the same width as the housing, and the bottom fluid channel 4 communicates with the rear end outlet 8 about the same width of the housing. The spoiler 2 evenly distributed on both sides and the upper part forms a shell, the outer surface 201 of the spoiler 2 is an arc surface, and the inner surface 202 is a plane, the front of each spoiler 2 is a pressure inlet 7, and the rear is a pressure outlet 5. There is a fluid layer 403 between the inner surface 202 of the spoiler and the inner shell 3, and a concave-convex spoiler surface 6 at the bottom, so that the path of the fluid passing through here is larger than its upper part.

[0060] When the train is running fast, a large amount of fluid at the front end is discharged from the large enough front inlet ...

Embodiment 3

[0066] Embodiment 3 is different from the above, Figure 5 Putting the maglev train into the cover body 1 (not shown), the paths of fluids on the inner and outer surfaces of multiple spoilers 2 around the train are different to generate a pressure difference, thereby forming a pressure difference transfer zone around the whole train. The cover body better transfers the high-pressure area around the train shell to the outer low-pressure area, so that the fluid resistance is greatly reduced. The maglev train has no friction between the wheels and the rails, and the pressure difference transfer area around the train makes the surrounding Fluid resistance is greatly reduced, so the movement speed is greatly improved.

[0067] This embodiment is not in the cover body, which can also increase the speed and save energy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com