Bored pile construction process

A technology of bored cast-in-place piles, construction technology, applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of concrete and mud loss, concrete and mud loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

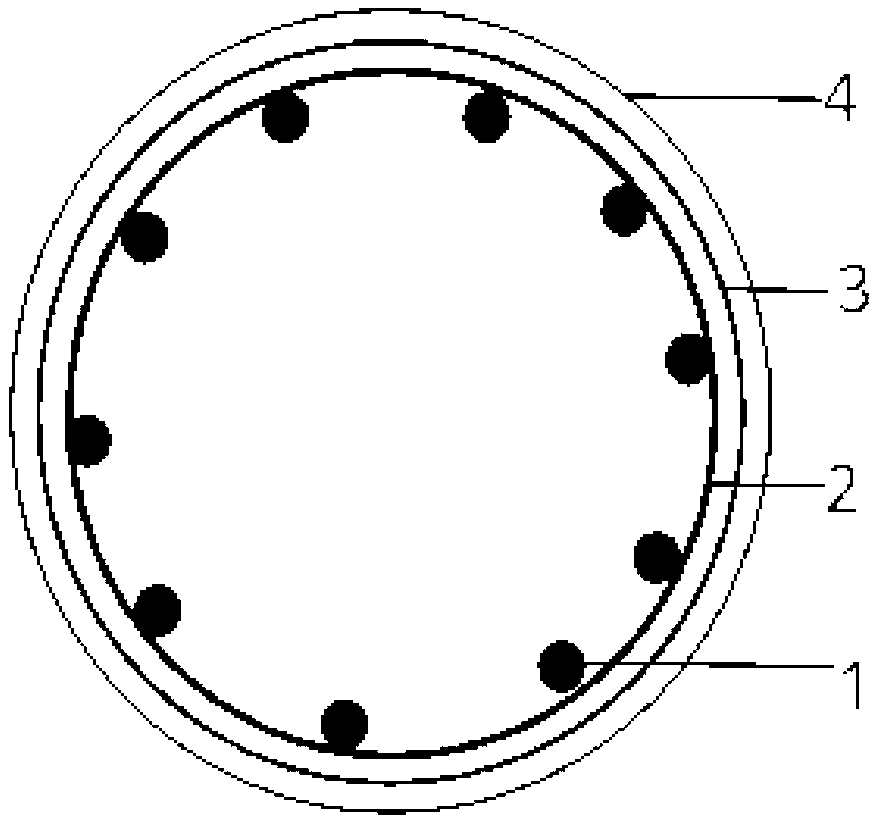

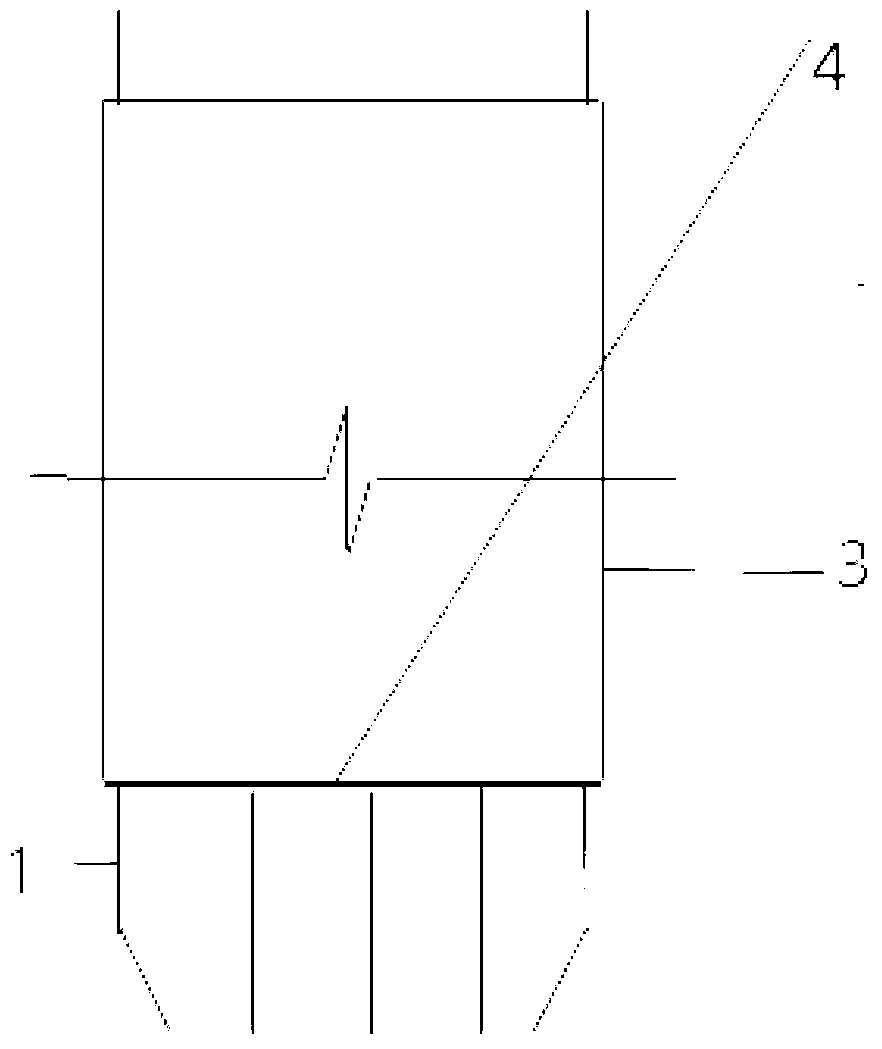

[0018] figure 1 with figure 2 Shows the specific structure of the reinforcement cage of the bored pile of the present invention, which includes the main reinforcement 1 of the reinforcement cage vertically surrounding the cylindrical shape and the stirrup 2 of the reinforcement cage bound on the main reinforcement of the reinforcement cage, and the reinforcement cage surrounds the main reinforcement of the reinforcement cage An expanded metal mesh 3 is provided, the thickness of the expanded metal mesh is 2 mm, and the mesh size of the expanded metal mesh is 10 mm×10 mm. A circle of stiffening hoops 4 with a diameter of 12 mm is welded and fixed at the bottom end of the expanded metal mesh. The stirrups of the steel cage and the expanded metal are firmly bound with galvanized iron wires. The overlapping length of the steel mesh around the reinforcement cage is 0.35m. Wherein the specification of reinforcement cage stirrup bar 2 is φ 8mm200. The specification of galvanized...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com