Navigation-hydraulic motor-driven device

A technology for motorized devices and navigation, which is used in transportation and packaging, ship propulsion, and ship parts, etc. It can solve problems such as consumption and large energy consumption, and achieve the effect of reducing friction and increasing negative pressure resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

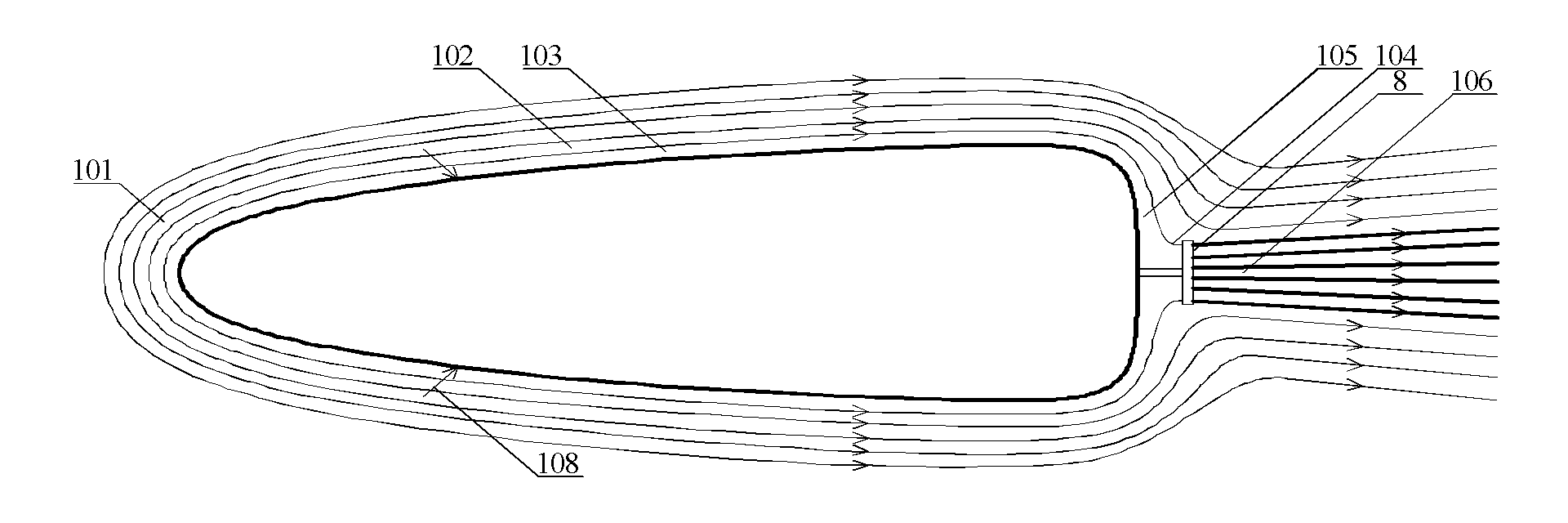

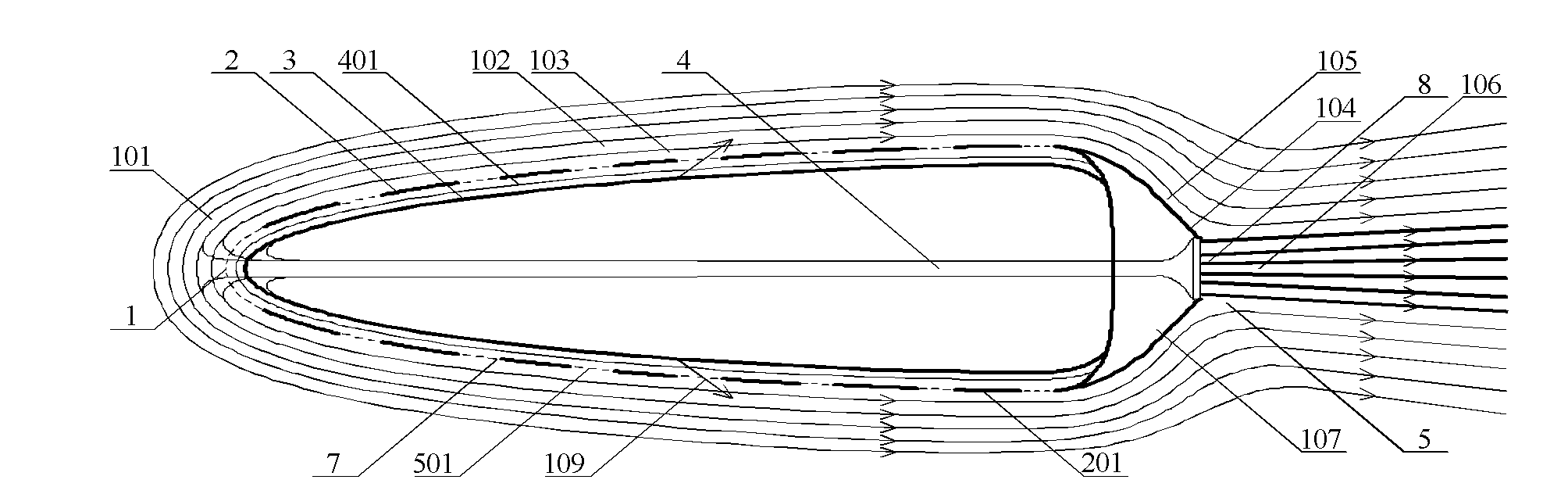

[0065] Example 1, such as Figure 2-6 As shown, the front end under the ship's waterline 301 is provided with a fluid inlet 1 with the same area as the fluid collision surface, which communicates with the tubular internal channel 4 and the fluid outlet 5 provided at the rear end, and a flow port 1 is provided at the rear under the ship's waterline. The shape of the linear guide body 107 can also be a semicircle, or a cone, or streamlined to facilitate the smooth flow of fluid without forming a small negative pressure zone. A fluid outlet 5 is provided at the intersection of the fluids in the middle of the guide body 107. It is convenient for the surrounding fluid to gather around the fluid outlet 5, and the propeller 8 is arranged in the fluid outlet 5, and the huge suction generated by the high-speed rotation of the propeller 8 can suck the fluid near the inlet 1 at a high speed, greatly reducing the resistance of the fluid wall, and conveniently The fluid is ejected at a hig...

Embodiment 2

[0071] Example 2, such as Figure 7-9 Shown, different from above-mentioned embodiment is that the fish scale is used as the spoiler, from the back of the ship forward and partially covered sequentially, the ship is under the waterline 301, and the scales on the shells on both sides are arranged the same as the scales on the body of the fish, evenly distributed with For the fish scale, the outer surface 201 of the fish scale is arc-shaped, and the inner surface 202 is plane. Between the inner surface 202 and the inner shell 3 is a fluid channel 401 .

[0072] When the ship is running fast, the fluid in the fluid channel 401 is already flowing, and the fluid is formed from the fish scales arranged with each other, and the arc-shaped peripheral edges of the unsealed outer surfaces 201 form a pressure inlet and outlet, and the fluid can be introduced there. Derived, a not wide fluid channel 401 is formed between the inner shell 3 and the flat inner surface 202 of the fish scales...

Embodiment 3

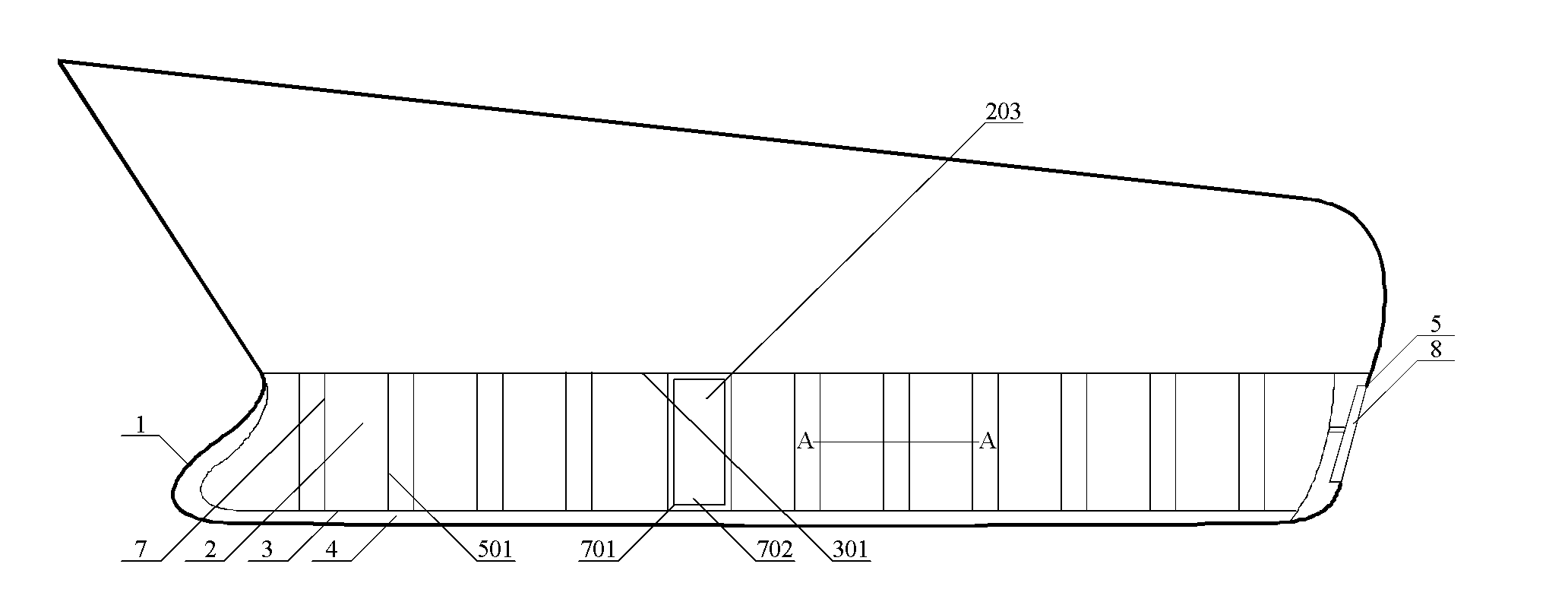

[0076] Example 3, such as image 3 , Figure 10-11 As shown, different from Embodiment 1, the internal passage 4 is located on the central axis of the part below the waterline of the hull, and a plurality of communicating through pipes 402 are provided between the shell of the ship and the internal passage 4, and the through pipes 402 communicates with the pressure inlet 703 of the casing. Of course, the through pipe 402 can be arranged between the hull of the bow of the ship and the internal channel 4 . The pressure inlets 703 to which these through pipes 402 are connected are located on both sides of the front of the ship where the forward fluid resistance is relatively large. A fluid channel 401 is formed between the outer shell and the inner shell 3 of the rear most part of the ship, and between a plurality of spoilers and the inner shell 3. The outer surface 201 of the spoiler is an arc surface, the inner surface 202 is a plane, and the rear propeller Change to suction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com