Reciprocating compressor

A compressor and reciprocating technology, which is applied in the direction of compressors, liquid variable capacity machines, refrigerators, etc., can solve problems such as large vibrations, and achieve the effects of improving reliability and efficiency, reducing side pressure, and reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

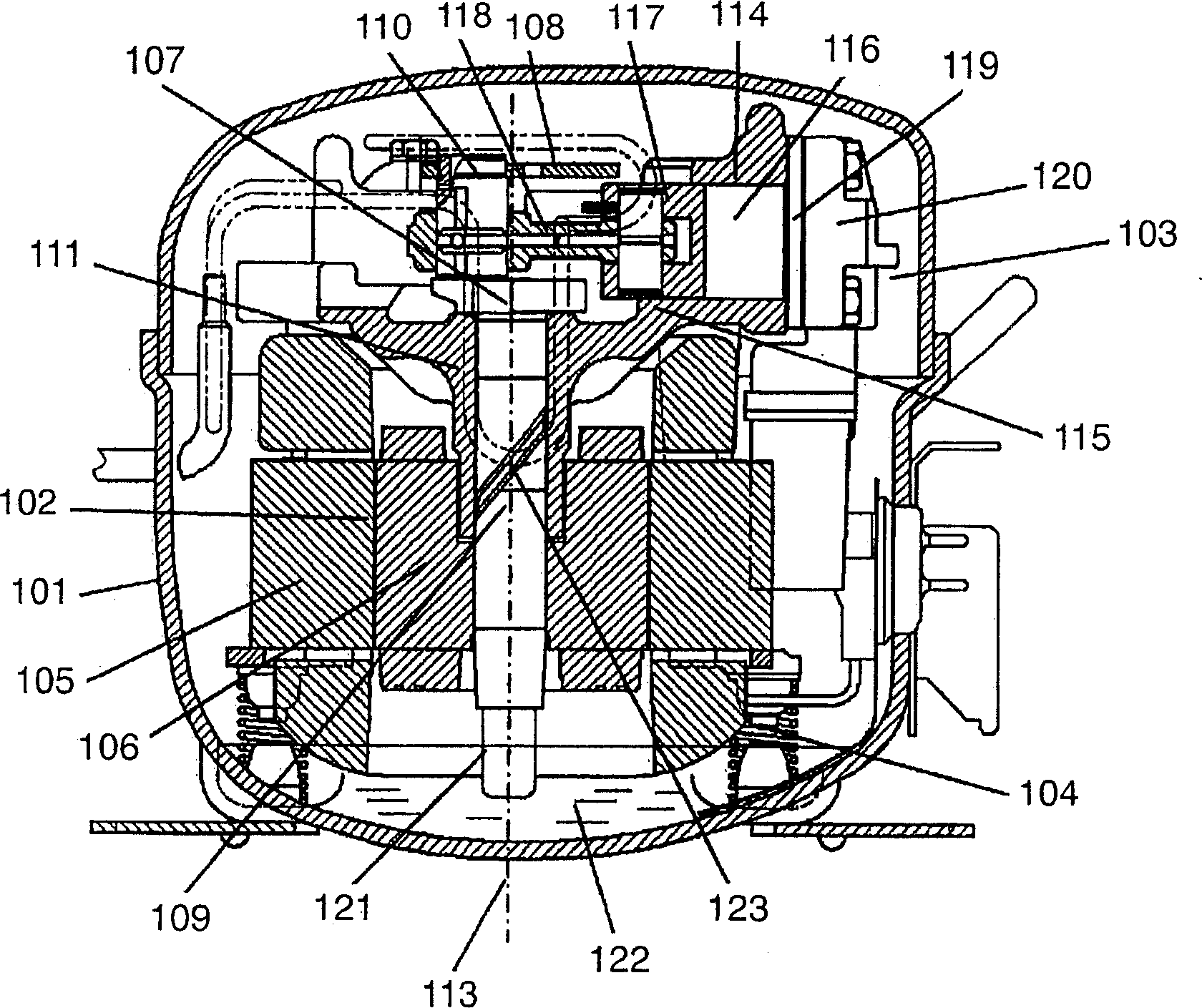

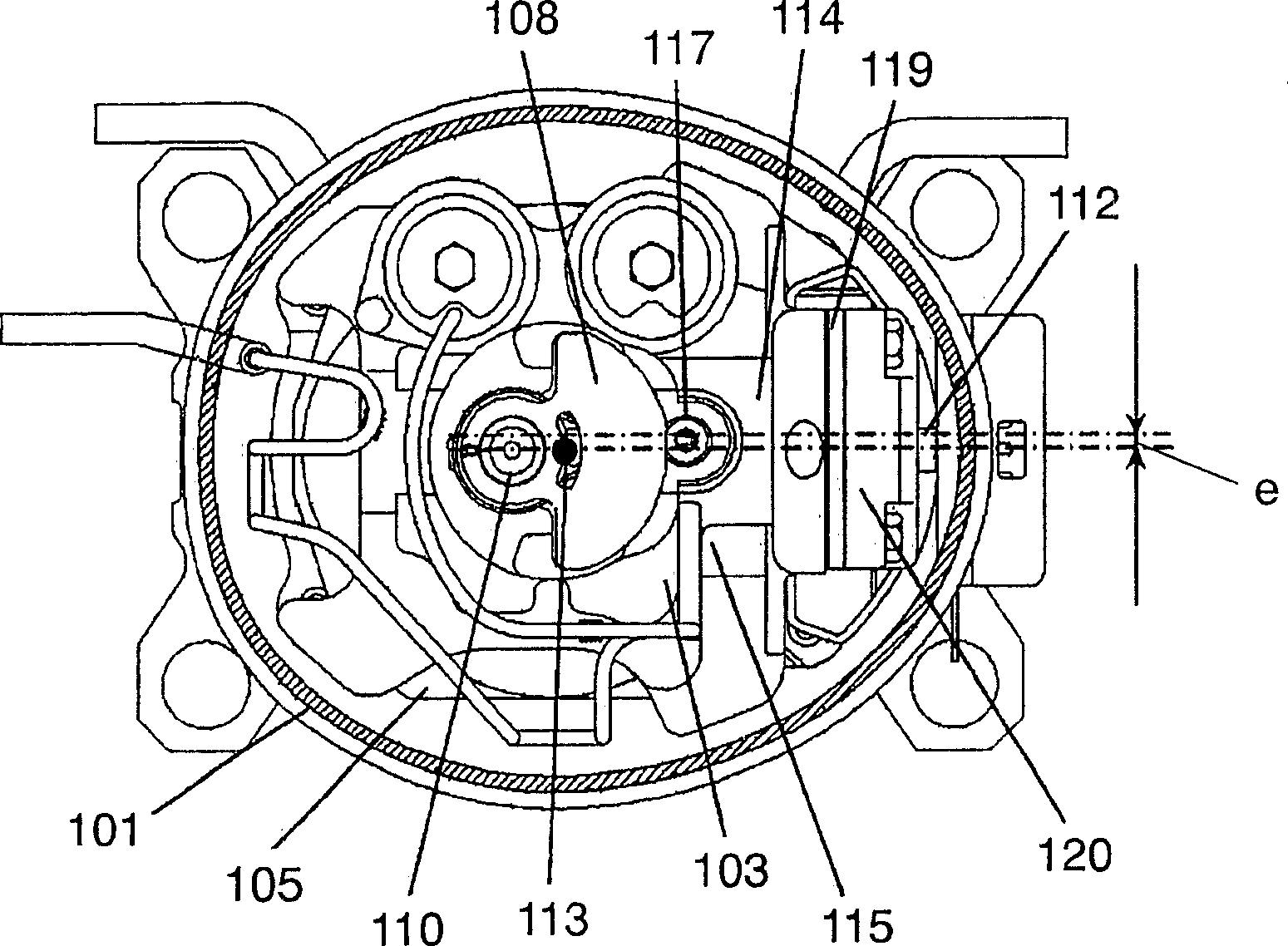

[0017] The reciprocating compressor of the present invention includes a hermetic container containing a compression element for compressing refrigerant gas. Compression elements consist of the following components:

[0018] a crankshaft arranged substantially vertically and having a main shaft portion and an eccentric portion;

[0019] forming a cylinder block of a cylindrical cylinder;

[0020] a piston reciprocating within the cylinder;

[0021] a connecting rod connecting the eccentric portion to the piston; and

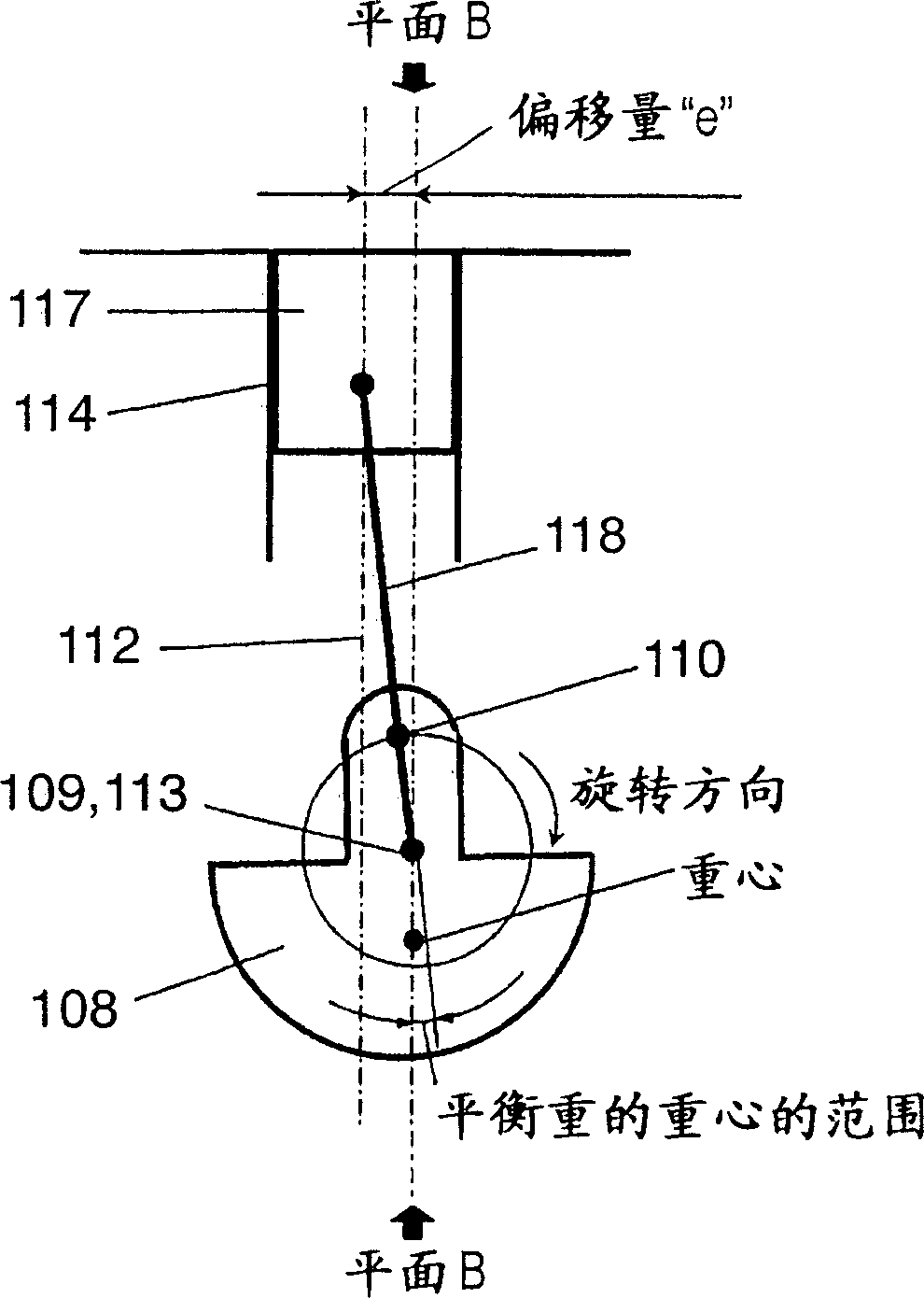

[0022] A balance weight for balancing vibrations generated by the above-mentioned members including at least one of a piston, a connecting rod, and an eccentric portion.

[0023] The cylinder is offset so that its axis and the axis of the main shaft part do not cross each other, and the balance weight is arranged so that its center of gravity is positioned substantially opposite to the center of the eccentric part with respect to the axis of the main shaft part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com