Reinforced fly ash soil retaining wall and construction method

A construction method, fly ash technology, applied in excavation, artificial islands, water conservancy projects, etc., can solve the problems that affect the popularization and application of reinforced soil retaining walls, weak connection between panels and reinforced soil, and low interface friction strength, etc., to achieve The structure is simple, the construction is convenient, and the effect of improving the friction performance of the interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

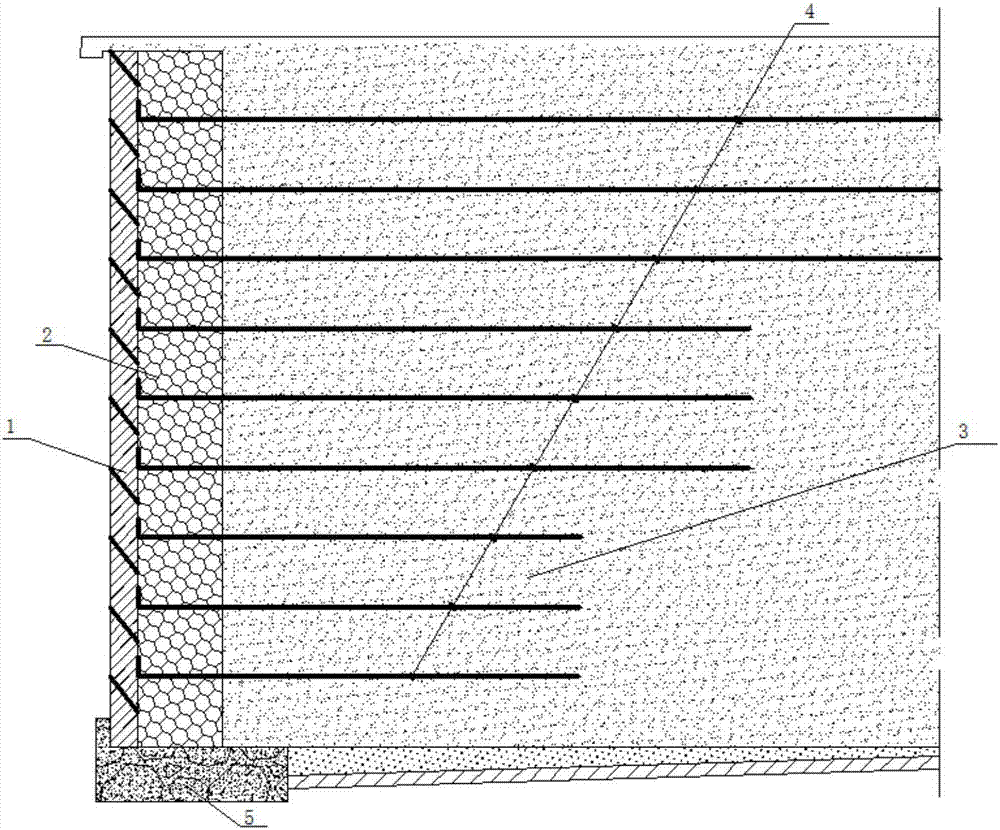

[0030] Below in conjunction with accompanying drawing, the present invention is further described: as figure 1 as shown,

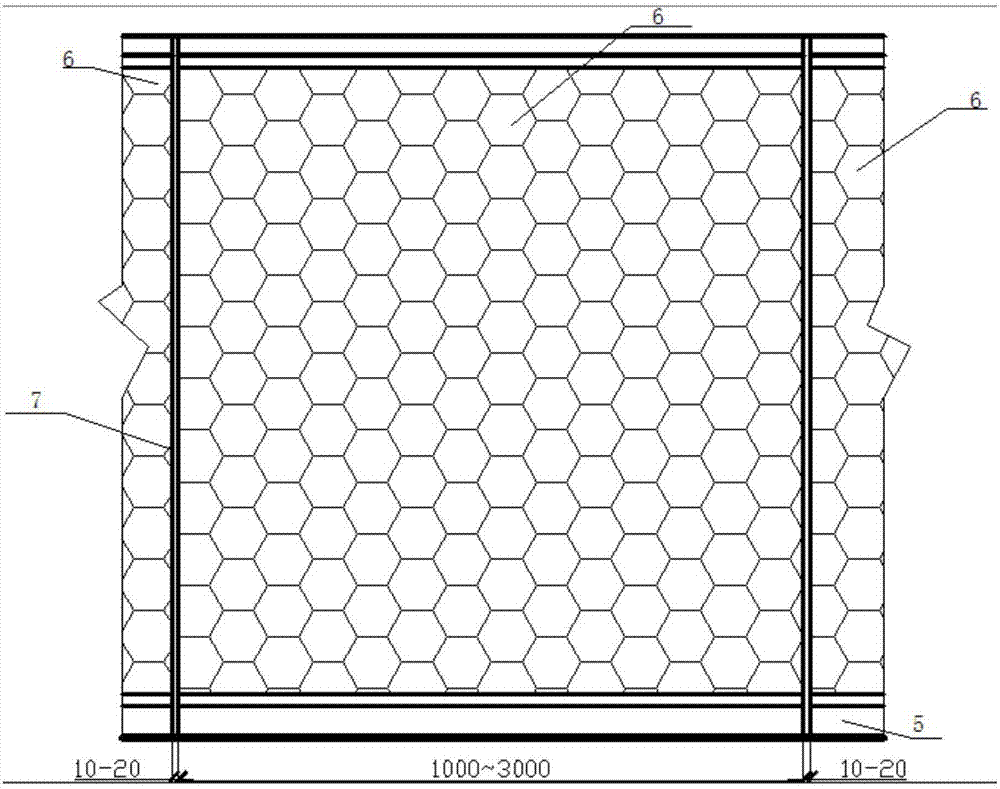

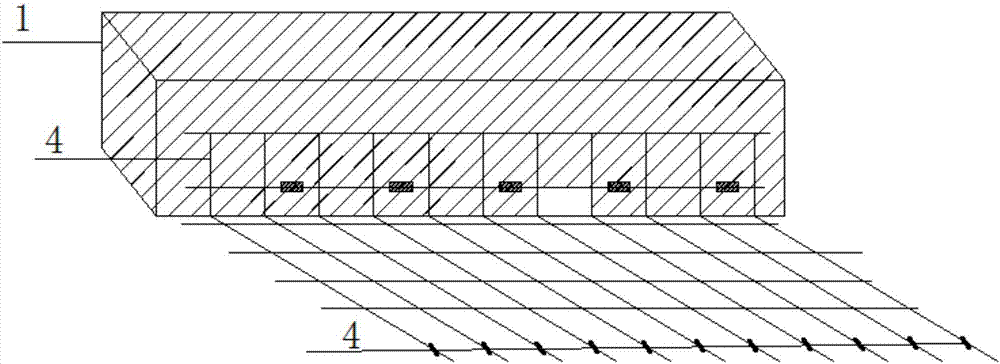

[0031] A reinforced fly ash retaining wall, which is composed of filler 3, reinforcement arranged in filler 3, and wall panel 1; wall panel 1 adopts prefabricated block 6 structure; EPS is set between wall panel 1 and filler 3 Foam plastic board 3; the filler 3 is saponification residue-fly ash-soil light filler; the reinforcement adopts geogrid 4, so that the drawing coefficient range is 0.54-0.85, and the geogrid 4 is directly pressed on the wall panel 1 between the upper and lower blocks 6.

[0032] In the saponification residue-fly ash-soil used in the filler 3: the particle size of the saponification residue is required to be between 0.075-2mm, and the CaO content of the saponification residue is greater than 45%.

[0033] The saponification residue-fly ash-soil used in the filler 3: fly ash requires SiO 2 and Al 2 o 3 The content of fly ash is g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com