Precast beam reinforcement cage component and assembling method thereof

An assembly method and steel cage technology, applied in the direction of building components, structural elements, building reinforcements, etc., can solve the problems of poor reliability, difficult construction, self-heavy PC components, etc., to meet construction requirements, simplify installation procedures, reduce The effect of working at heights

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

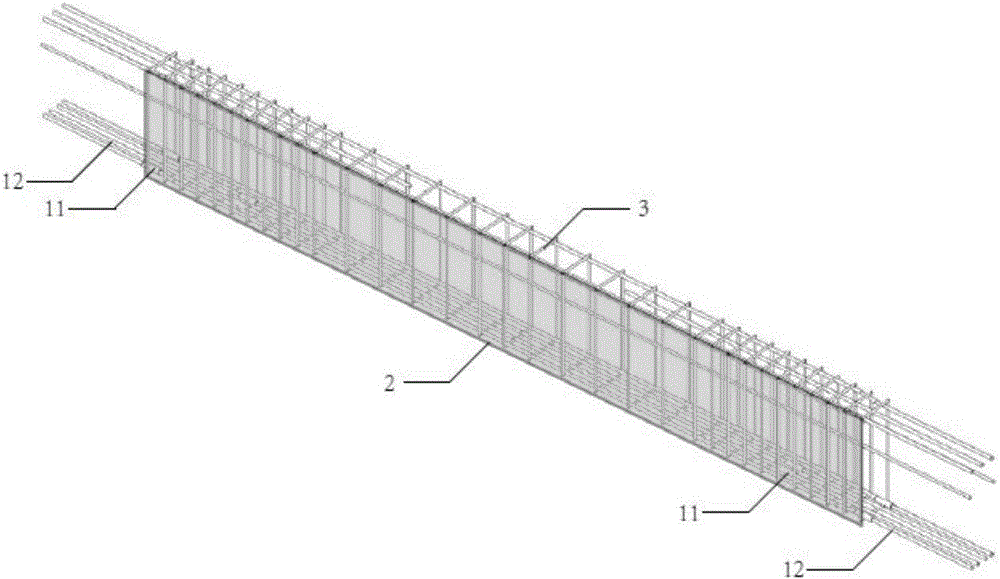

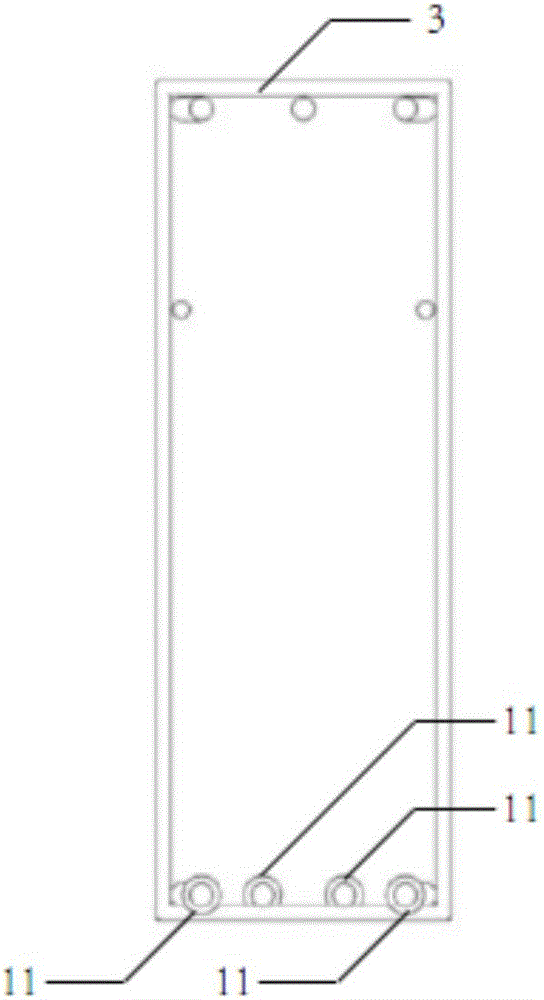

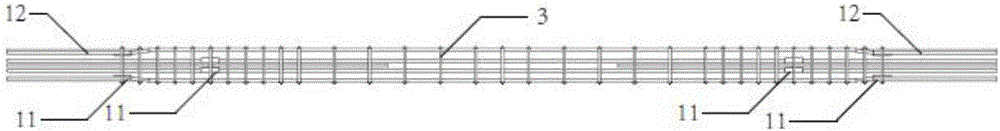

[0032] The prefabricated beam reinforcement cage member of the present invention comprises a steel bar assembly 1, a demolition-free formwork 2 arranged along the front and rear sides and bottom surfaces of the beam, and the demolition-free formwork 2 is connected with the steel bar assembly 1 through a positioning fixture, and the steel bar assembly 1 It is connected by horizontal reinforcement and stirrup. The prefabricated beam reinforcement cage member in the present invention may consist of only one reinforcement assembly 1 or may consist of multiple reinforcement assemblies 1 . Wherein, the dismantling-free formwork 2 adopts a dismantling-free mesh formwork or a dismantling-free formwork, and the positioning and fixing parts adopt connecting ribs or edge frames.

[0033] In one embodiment of the present invention, the following structure is adopted: on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com