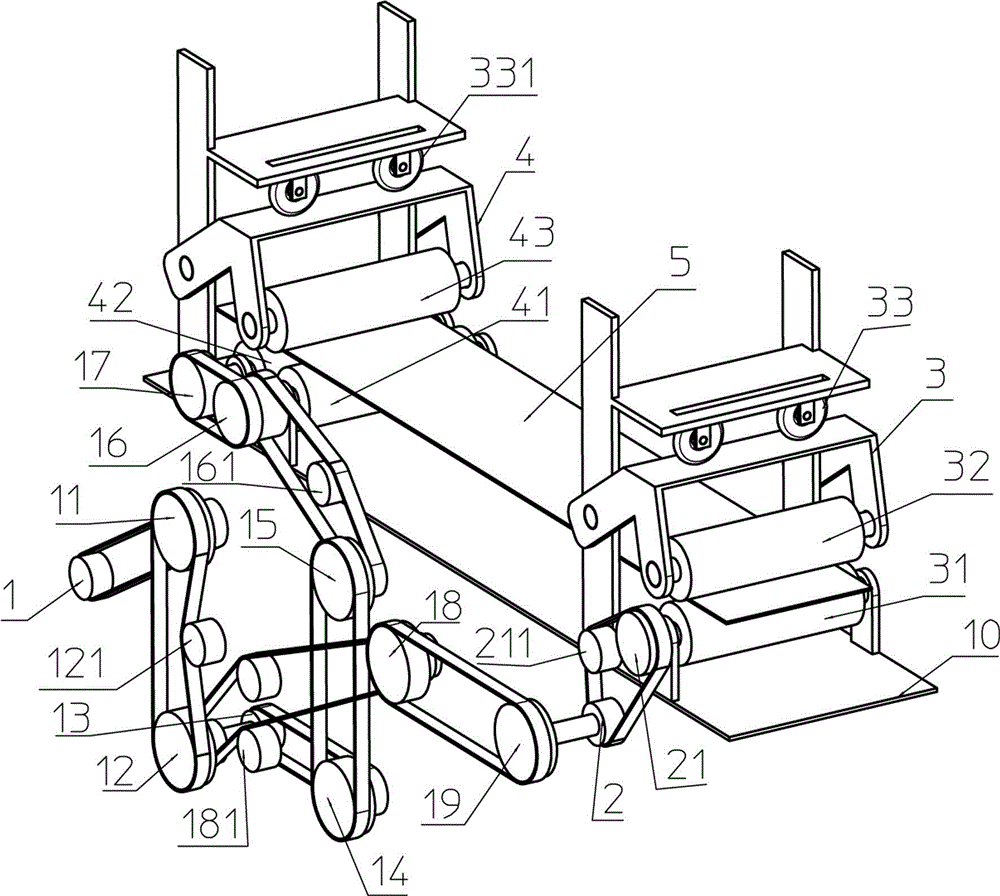

Main drafting device of wool top cut-off machine

A drafting device and cutting machine technology, applied in drafting equipment, spinning machines, textiles and papermaking, etc., can solve problems such as poor drafting effect of wool tops, unsteady rotation speed, easy slipping of transmission belts, etc., and achieve good results. Drafting, low noise, not easy to slip effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below with reference to specific embodiments and accompanying drawings. In order to clearly reflect the relevant structure of the main drafting device in the top cutting machine, only part of the frame is shown in the drawings.

[0015] Main drafting units in top cutting machines, such as figure 1 As shown, the frame 10 is included, and a front drafting roller set is installed at the front of the frame 10. The front drafting roller set includes a front pinch roller 32 and a front pull roll 31, and the front pinch roll 32 is located in the front pull roll 31. Above, the front pressing roller 32 is installed on the front elastic support 3 through the bearing, the front elastic support 3 is hinged with the frame 10, the front traction roller 31 is installed on the frame 10 through the bearing, and also above the front elastic support 3 A front pressing device is provided, and the front pressing device can make the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com