Processing method of ferrous metal super-finishing surface

A ferrous metal and processing method technology, applied in metal processing equipment, metal processing mechanical parts, metal material coating technology and other directions, can solve the problems of gaps and limited effect of diamond tool wear, achieve inhibition of wear and improve chemical reduction. The effect of grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

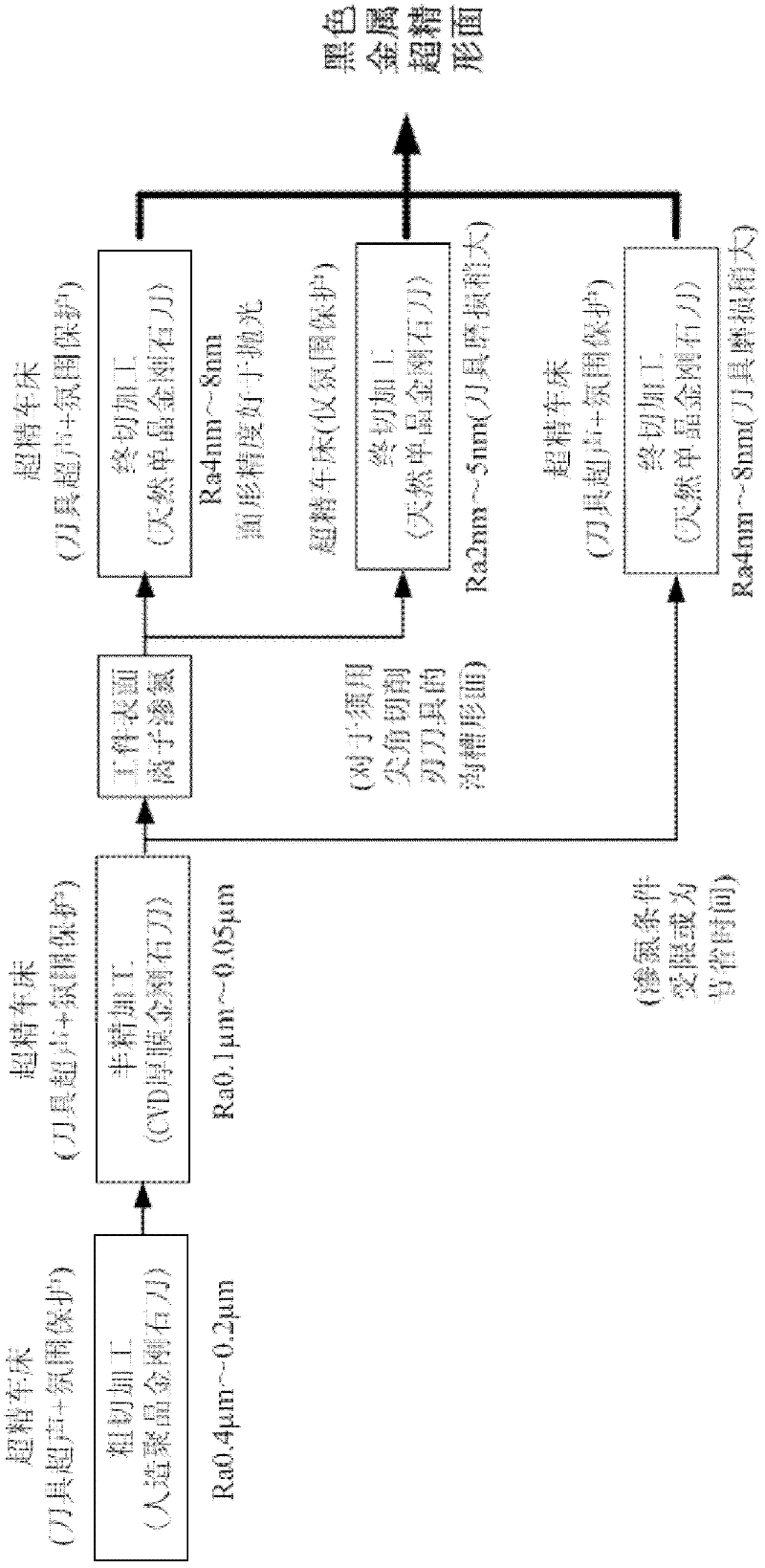

[0037] Embodiment 1: It is used to process super-precision surfaces with conductable curvature. This type of surface includes flat, spherical, quadratic and cubic curved surfaces. At this time, the present invention includes the following implementation steps:

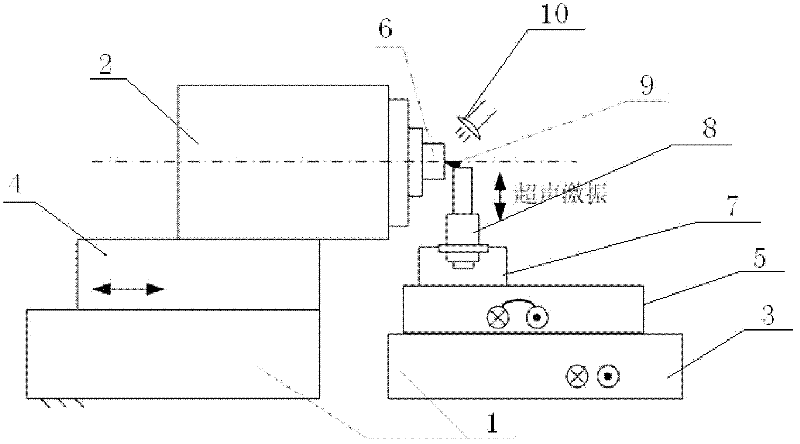

[0038] 1) Preparation before processing: an ultra-precision or precision CNC lathe must be provided, which has at least a main shaft and two linear servo axes x and z to turn complex surfaces; the ultrasonic excitation device is installed vertically as a functional component On the base of the lathe, the lower end is connected to the base of the lathe through a flange, and the upper end is equipped with a diamond tool; the piezoelectric ceramic drive power is prepared and connected to the electrode of the ultrasonic excitation device transducer; the carbon-containing cutting fluid is prepared, and the Under simple conditions, the graphite powder particles can be used as printer toner, and the cutting fluid after adding gra...

Example Embodiment

[0043] Embodiment 2: It is used to process super-precision surfaces with non-conductive curvature, such as Fresnel mirrors, groove array surface structures, etc. At this time, the present invention includes the following implementation steps:

[0044] 1) Preparation before processing: Same as the first embodiment.

[0045] 2) Rough cutting: same as the first embodiment.

[0046] 3) Semi-finishing: The tool is changed to a CVD thick-film diamond tool with a rake angle of 0, a back angle of 10, and a sharp cutting edge; the rest is the same as the first embodiment; during the machining process, the CNC program is used to initially cut the contour.

[0047] 4) Perform surface ion nitriding treatment on the semi-finished workpiece; the same as the first embodiment.

[0048] 5) Final cutting processing: processing with a natural single crystal diamond tool with sharp cutting edges; cutting tool rake angle 0, relief angle 5, tool tip angle and fillet are designed according to the shape to be ...

Example Embodiment

[0049] Embodiment 3: In the case of limited nitriding treatment conditions or strict time and cost control, the nitriding treatment on the surface of the workpiece can be omitted; because the ultrasonic vibration of the tool and the protection of the cutting fluid atmosphere can also be used at the same time to achieve better Diamond tool wear reduction effect; if the physical and chemical properties of the workpiece surface are required at the same time, quenching treatment can be added before the final machining. At this time, the specific implementation is as follows:

[0050] 1) Preparation before processing: Same as the first embodiment.

[0051] 2) Rough cutting: same as the first embodiment.

[0052] 3) Semi-finishing: According to the characteristics of the processed surface, the corresponding steps of Embodiment 1 or Embodiment 2 are adopted accordingly.

[0053] 4) If there are physical and chemical performance requirements for the surface of the workpiece, surface quenching...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com