Ordered arrangement method for abrading agent granule on abrading tool and abrading tool

A technology of orderly arrangement of abrasive particles, applied in abrasives, manufacturing tools, metal processing, etc., can solve problems such as inability to effectively control the uniform distribution of diamonds in tools, impossibility of industrialization, and impossible setting of diamond arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

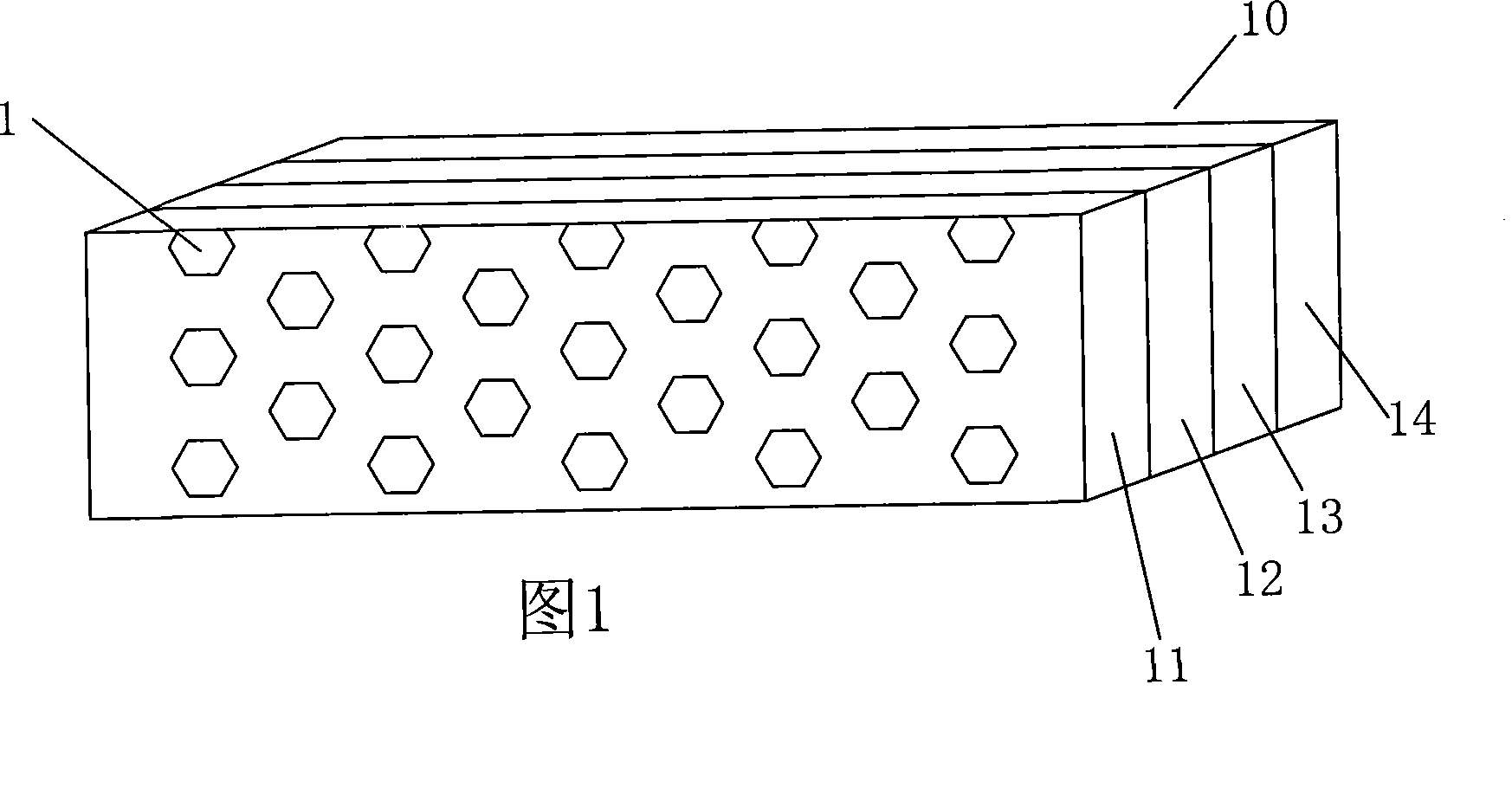

[0042] Referring to Figure 1, it shows a perspective view of a part on the cutting end of a diamond tool, marked 10, which part 10 is made up of three layers of carcass 11, 12, 13, 14, and the hexagonal blocks 1 in these layers are represented as abrasive particles;

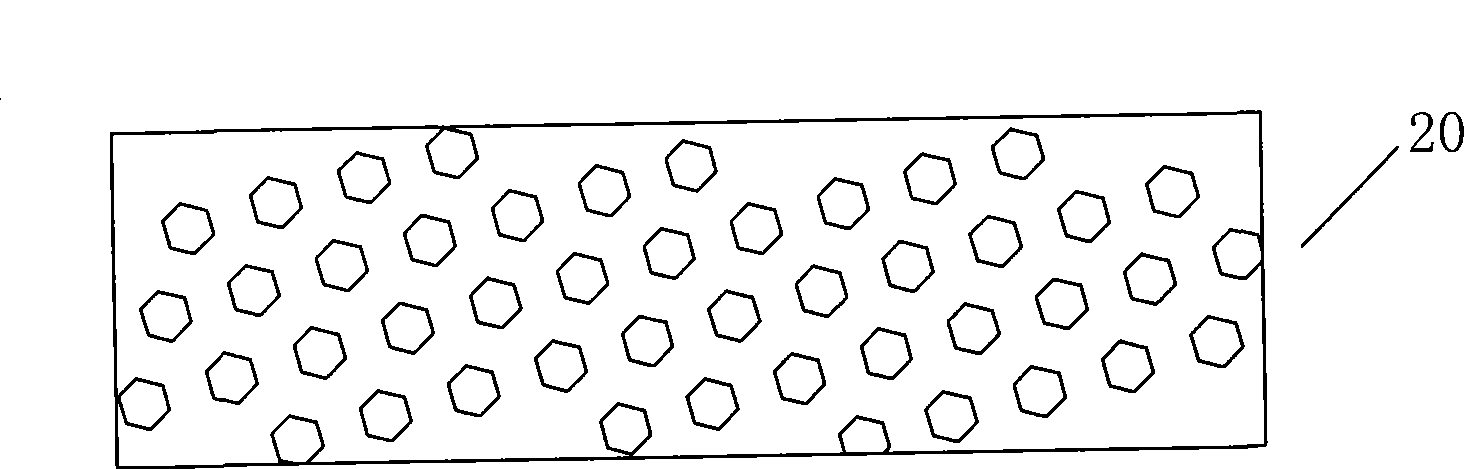

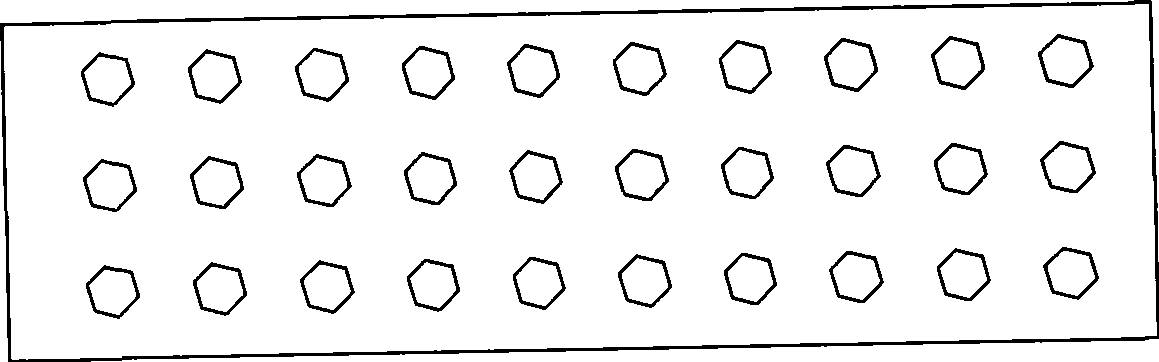

[0043]Referring to Fig. 2, the present invention adopts a kind of electromagnetic adsorption plate 20, and it has single-layer adsorption ability after corona treatment, and it can adsorb abrasive particle diamond,, because after absorbing last layer diamond or, its adsorption position is occupied, other Abrasive particles are no longer adsorbed, so it is a single layer, and the adsorption plate can be designed according to the requirements of diamond or other abrasives. Therefore, diamond and silicon nitride are ordered and oriented on the middle adsorption plate Arrangement, and this arrangement can be realized by arbitrarily designing the adsorption plate according to the designer's requirements.

[0044] The ...

Embodiment 2

[0053] The adsorption bottom plate of this embodiment is a band of adhesive, and its adsorption capacity is adsorbed by chemical substances, which is different from the electric and magnetic adsorption of the embodiment, and the rest are the same.

Embodiment 3

[0055] Select 40 / 50 U.S. mesh diamond particles (SDA-85 manufactured by DE BEERS Company), the matrix material is a mixture of metal powder and acrylic resin, the metal powder contains five different cobalt and bronze, prepared in proportion, and bonded with acrylic resin The agent is added to the prepared powder, mixed into a block, and the block is sent to a roller calender to be pressed into a thin sheet with a thickness of 1mm. The adsorption plate with the above-mentioned diamond particles is set on the above-mentioned sheet, pressed into Diamond in the sheet, separate the adsorption plate, cut the sheet into 40mm long and 15mm wide diamond sawtooth, assemble three such sawtooth layers together and place in a graphite mold to make traditional diamond sawtooth, the graphite mold The three sawtooth layers are pressed together by electric heating, and after about three minutes of sintering, the sawtooth is sintered to a height of 9mm and with pores less than 1%. Twenty-four ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com