Laminated bottom antireflex structure and etching method

A bottom anti-reflection and bottom anti-reflection layer technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as graphics influence and semiconductor device quality, and achieve the effect of maintaining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

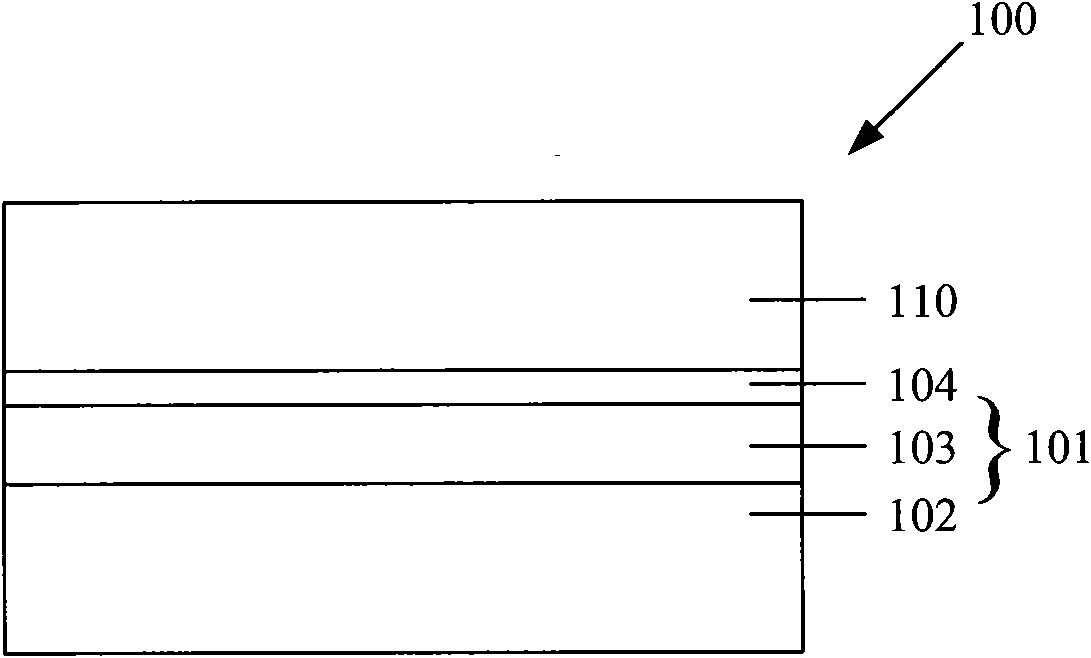

[0024] Such as figure 1 As shown, the specific embodiment provides a laminated structure 100 for photolithography, including a bottom anti-reflection layer 101 and a photoresist layer 110 thereon. The bottom anti-reflection layer 101 is an organic bottom anti-reflection layer 102 with a thickness of about 100 nm. The organic bottom anti-reflection layer 102 is provided with a silicon-containing bottom anti-reflection layer 103 with a thickness of about 50 nm. A silicon oxide layer 104 with a thickness of about 5 nm is also provided on the layer 103. The material forming the organic bottom anti-reflective layer 102 may be an organic anti-reflective material of ODL63 produced by Shin-Etsu Company of Japan. The material for forming the silicon-containing bottom anti-reflective layer 103 may be a silicon-containing anti-reflective material produced by Shin-Etsu Company under the brand name SHB A629.

[0025] The reason for forming the laminated bottom anti-reflective structure 101 w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com