Addition type composite particle for polyester film, preparation method of addition type composite particle and optical polyester film added with composite particle

A technology of polyester film and composite particles, which is applied in the field of polyester film, can solve the problems affecting the light transmittance of polyester film, etc., and achieve the effects of good sliding and scratch resistance, low haze and high light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

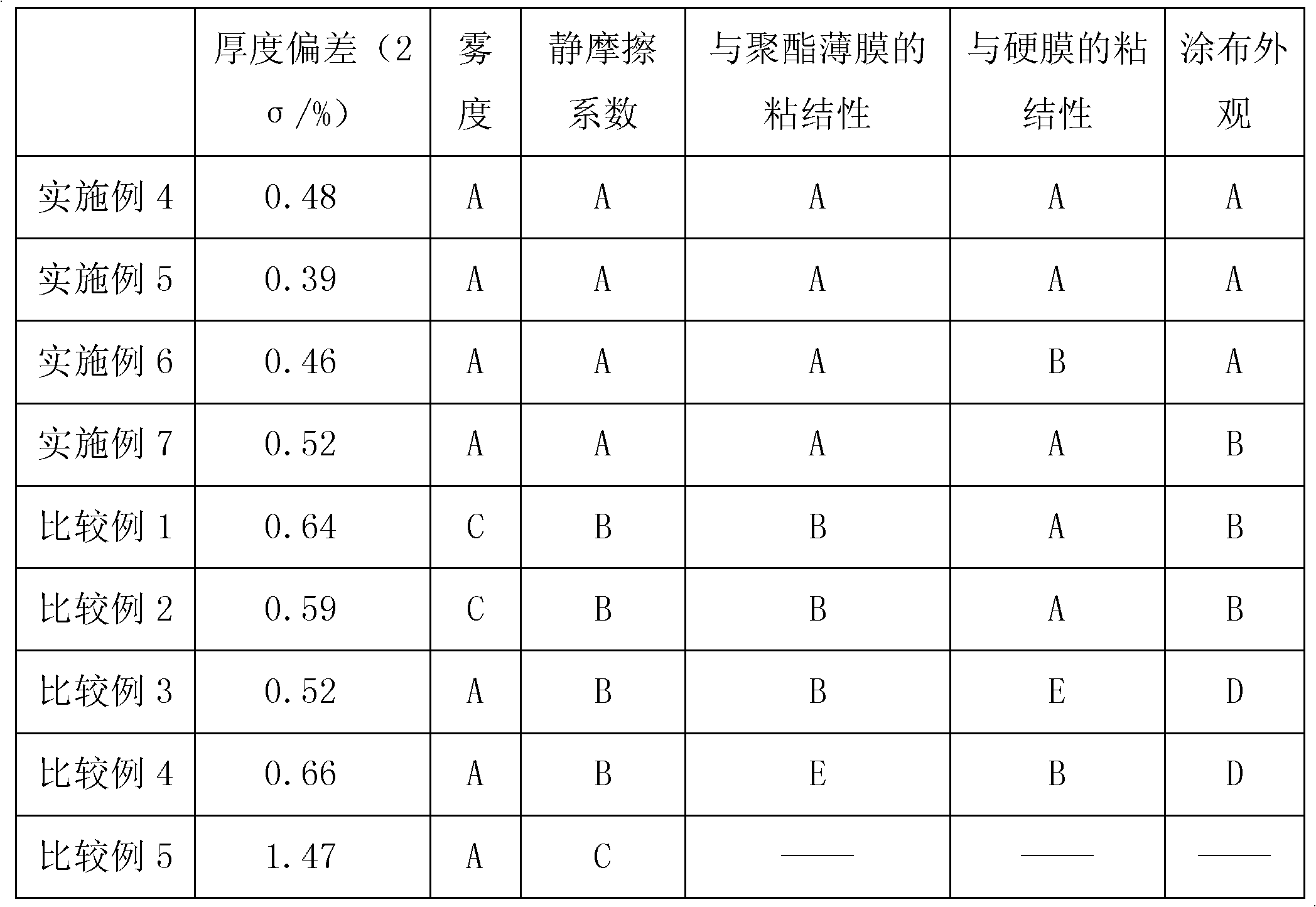

Examples

Embodiment 1

[0047] (1) In parts by weight, under agitation, 140 parts of methanol, 260 parts of isopropanol and ammonia water (100 parts of ammonia solution) containing 25 parts of ammonia are mixed to prepare a reaction solution, and the temperature of the reaction solution is maintained at 40° C. Keep stirring.

[0048] (2) Add 200 parts of methanol and 0.1 parts by weight of Hcl-containing aqueous hydrochloric acid (35% hydrochloric acid diluted to 1 / 1000 with water) to 540 parts of silicon tetramethoxide under stirring, and stir for 10 minutes.

[0049] (3) After diluting 350 parts of titanium tetraisopropoxide with 730 parts of isopropanol, add the diluted solution to the solution of (2) and mix to obtain a transparent homogeneous solution (tetraalkoxy silicon and tetraalkoxy titanium of cocondensates).

[0050] (4) Within 2 hours, the homogeneous solution and the ammoniacal liquor (480 parts in aqueous ammonia solution) containing 25 parts of ammonia were added dropwise in the reac...

Embodiment 2

[0052] (1) In parts by weight, under stirring, 120 parts of methanol, 250 parts of isopropanol and ammonia water (60 parts of ammonia solution) containing 20 parts of ammonia are mixed to prepare a reaction solution, and the temperature of the reaction solution is maintained at 35° C. Keep stirring.

[0053] (2) Add 200 parts of methanol and an aqueous hydrochloric acid solution (35% hydrochloric acid diluted to 1 / 1000 with water) containing 0.08 parts by weight of Hcl to 500 parts of silicon tetramethoxide under stirring, and stir for 8 minutes.

[0054] (3) After diluting 300 parts of titanium tetraisopropoxide with 600 parts of isopropanol, add the diluted solution to the solution of (2) and mix to obtain a transparent homogeneous solution (tetraalkoxy silicon and tetraalkoxy titanium of cocondensates).

[0055] (4) Within 1.5 hours, the homogeneous solution and the ammoniacal liquor (300 parts of ammonia solution) containing 20 parts of ammonia were added dropwise to the ...

Embodiment 3

[0057] (1) In parts by weight, under agitation, 200 parts of methanol, 330 parts of isopropanol and ammonia water containing 30 parts of ammonia (180 parts of ammonia solution) are mixed to prepare a reaction solution, and the temperature of the reaction solution is maintained at 50° C. Keep stirring.

[0058] (2) Add 280 parts of methanol and 0.15 parts by weight of Hcl-containing aqueous hydrochloric acid (35% hydrochloric acid diluted to 1 / 1000 with water) to 600 parts of silicon tetramethoxide under stirring, and stir for 20 minutes.

[0059] (3) After diluting 420 parts of titanium tetraisopropoxide with 730 parts of isopropanol, add the diluted solution to the solution of (2) and mix to obtain a transparent homogeneous solution (tetraalkoxy silicon and tetraalkoxy titanium of cocondensates).

[0060] (4) Within 4 hours, the homogeneous solution and the ammoniacal liquor (550 parts in aqueous ammonia solution) containing 30 parts of ammonia were added dropwise in the rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com