Substrate applying method, touch control display substrate and display apparatus

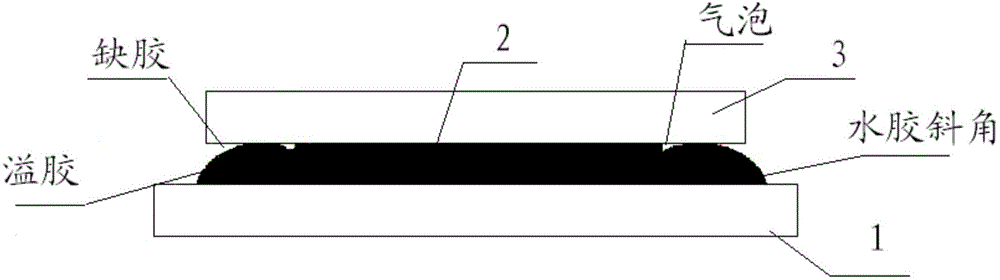

A technology for touch display substrates and display devices, applied in lamination devices, chemical instruments and methods, lamination auxiliary operations, etc., can solve problems such as easy generation of air bubbles, overflowing glue, and lack of glue, so as to reduce lamination air bubbles, Guaranteed optical performance and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

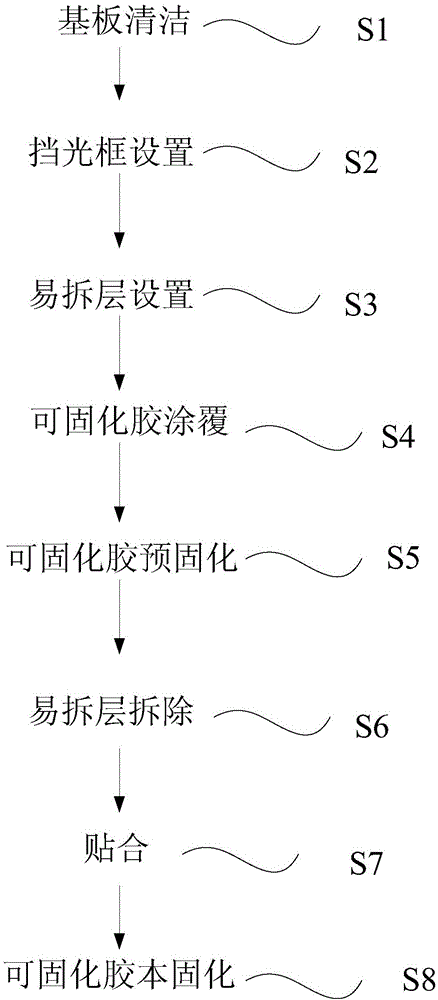

[0043] This embodiment provides a substrate bonding method, including the following steps:

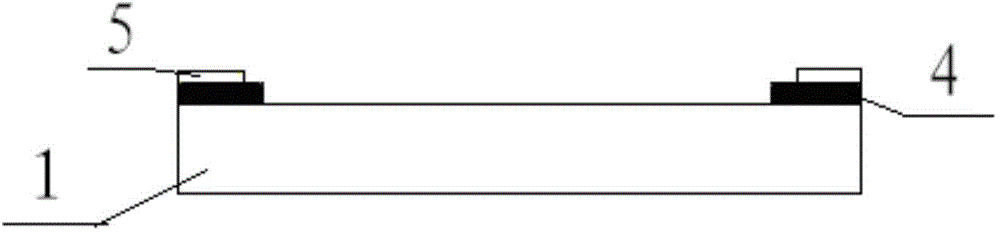

[0044] setting a light shielding frame in the peripheral area of the surface to be bonded of the first substrate;

[0045] An easily detachable layer is set on the light blocking frame;

[0046] Coating curable glue on the surface to be bonded of the first substrate;

[0047] Pre-cure the curable glue;

[0048] The easy-detachable layer is removed, and the curable glue attached to the easy-detachable layer is removed at the same time.

[0049] In the substrate laminating method, touch display substrate and display device of the present invention, since an easy-to-detachable layer is provided around the first substrate, and then the curable adhesive is applied, the curable adhesive is pre-cured and the easy-to-detachable layer is removed to enable The curable adhesive forms a special-shaped shape, the thickness of the curable adhesive layer is uniform, the surface is smooth, and th...

Embodiment 2

[0078] This embodiment provides a touch display substrate, and the touch display substrate is prepared by using the above-mentioned substrate bonding method.

[0079] Since the touch display substrate of this embodiment is prepared by the above-mentioned substrate bonding method, the optical performance of the touch display substrate is relatively good.

Embodiment 3

[0081] This embodiment provides a display device, which includes a touch display substrate.

[0082] Since the display device of this embodiment includes the above-mentioned touch display substrate, the optical performance of the display device is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com