Composite photocatalytic coating and preparation method thereof

A technology of composite photocatalysis and coating, which is applied in the field of preparation of composite photocatalysis coating, can solve the problems of low preparation efficiency, limitation, long time and so on, and achieve the effect of enhancing the photocatalytic function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

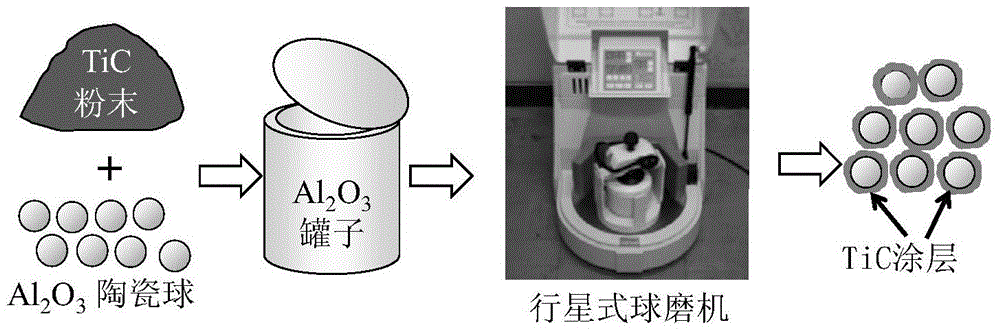

[0060] Main equipment: 1 planetary ball mill, 1 heat treatment furnace

[0061] Main raw materials and process parameters: micron-sized TiC powder (2-5 microns), Al 2 o 3 Ceramic balls (average particle size 1-5 mm), the mass percentage range of the two is 40%-50% and 60%-50%, the total volume of the two accounts for 20%-50% of the volume of the ball mill tank; planetary ball mill revolution The speed is 100-600 rpm, and the ball milling time is 1-20 hours.

[0062] Preparation of TiC coating:

[0063] The above TiC powder and Al 2 o 3 The ceramic balls are mixed according to the mass ratio and put into the ball mill jar, and then ball milled on the planetary ball mill, relying on the centrifugal force generated by the ball mill to make the TiC powder and Al 2 o 3 The ceramic balls collide and rub against the inner wall of the ball mill jar. Under the action of the collision force and friction force, the TiC powder can 2 o 3 The surface of the ceramic ball is adhered, ...

Embodiment 2

[0072] Mechanical coating: 60g of Al with a diameter of 1mm 2 o 3 Ceramic balls and 40g of TiC powder with a particle size of 2 to 5 μm are charged into a 250ml Al 2 o 3 Then place the ball mill jar on a planetary ball mill for mechanical coating, the revolution speed of the ball mill is set to 480r / min, and the time is set to 10 hours.

[0073] heat treatment:

[0074] Group C-1073K: TiC-coated Al 2 o 3 The ceramic ball is equally divided according to Figure 6 The method shown is placed in a muffle furnace for heat treatment. The heat treatment temperature is set to 1073K, the heating rate is 30K / min, and the maintenance time is 15 hours. After the furnace cools to room temperature, the sample can be taken out of it to complete the sample preparation;

[0075] Group O-1073K: TiC-coated Al 2 o 3 The ceramic balls are directly heat-treated in the atmosphere. The temperature of the heat treatment is 1073K, the heating rate is 30K / min, and the maintenance time is 15 hour...

Embodiment 3

[0086] Mechanical coating: 50g of Al with a diameter of 7-10mm 2 o 3 Ceramic balls and 50g of TiC powder with a particle size of 5-9μm are charged into a 250ml Al 2 o 3 Then place the ball mill jar on a planetary ball mill for mechanical coating, the revolution speed of the ball mill is set to 500r / min, and the time is set to 8 hours.

[0087] heat treatment:

[0088] Group C-1073K: TiC-coated Al 2 o 3 The ceramic ball is equally divided according to Figure 6 The method shown is placed in a muffle furnace for heat treatment. The heat treatment temperature is set to 1273K, the heating rate is 35K / min, and the maintenance time is 12 hours. After the furnace cools to room temperature, the sample is taken out of it to complete the sample preparation;

[0089] Group O-1073K: TiC-coated Al 2 o 3 The ceramic balls are directly heat-treated in the atmospheric environment, the temperature of the heat treatment is 1273K, the heating rate is 35K / min, and the maintenance time is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com