Preparation method of composite photocatalytic coating and prepared composite photocatalytic coating

A composite photocatalysis and coating technology, which is applied in the field of preparation of composite photocatalytic coatings, can solve the problems of low preparation efficiency, large equipment cost, large-scale special equipment, etc., and achieve the effect of enhancing photocatalytic function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

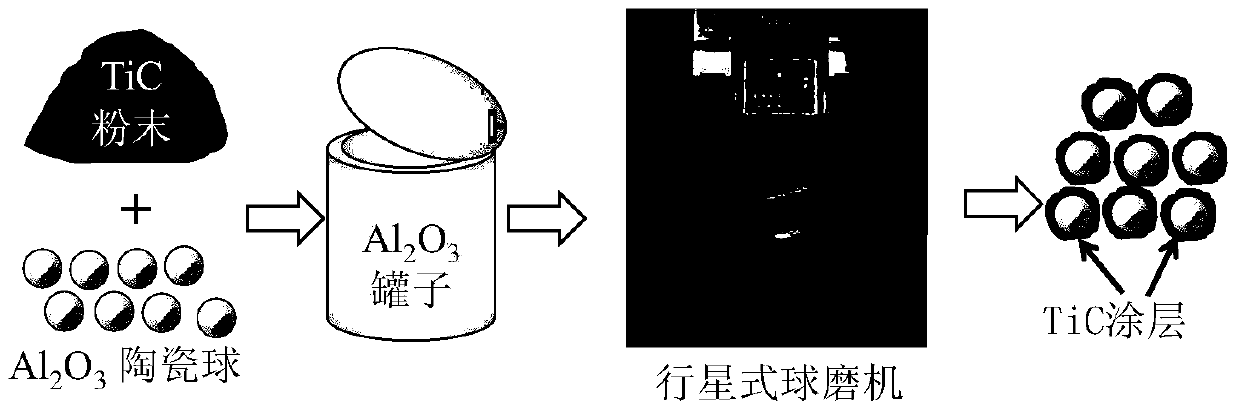

[0060] Main equipment: 1 planetary ball mill, 1 heat treatment furnace

[0061] Main raw materials and process parameters: micron TiC powder (2-5 microns), Al 2 O 3 Ceramic balls (average particle size 1-5 mm), the mass percentage of the two ranges from 40% to 50% and 60% to 50%, the total volume of the two occupies 20%-50% of the volume of the ball mill tank; planetary ball mill revolution The speed is 100 to 600 revolutions per minute, and the ball milling time is 1 to 20 hours.

[0062] Preparation of TiC coating:

[0063] Combine the above TiC powder and Al 2 O 3 The ceramic balls are mixed and put into a ball mill tank according to the mass ratio, and then ball milled on a planetary ball mill. The centrifugal force generated by the ball mill makes the TiC powder and Al 2 O 3 The ceramic balls collide and friction with the inner wall of the ball mill. Under the impact and friction, the TiC powder can be in Al 2 O 3 The surface of the ceramic ball adheres. After a certain period o...

Embodiment 2

[0072] Mechanical coating: 60g of Al with a diameter of 1mm 2 O 3 Ceramic balls and 40g TiC powder with a particle size of 2~5μm are filled into 250ml Al 2 O 3 Put the ball mill on a planetary ball mill for mechanical coating. The revolution speed of the ball mill is set to 480r / min and the time is set to 10 hours.

[0073] Heat treatment:

[0074] Group C-1073K: The prepared Al coated with TiC coating 2 O 3 Ceramic balls are divided equally according to Image 6 The method shown is placed in a muffle furnace for heat treatment, the heat treatment temperature is set to 1073K, the heating rate is 30K / min, and the maintenance time is 15 hours. After the furnace is cooled to room temperature, the sample is taken out to complete the sample preparation;

[0075] O-1073K group: the prepared Al coated with TiC coating 2 O 3 The ceramic balls are directly heat-treated in the atmosphere. The heat-treatment temperature is 1073K, the heating rate is 30K / min, and the maintenance time is 15 hours....

Embodiment 3

[0086] Mechanical coating: 50g of Al with a diameter of 7-10mm 2 O 3 Ceramic balls and 50g of TiC powder with a particle size of 5-9μm are filled into 250ml of Al 2 O 3 Put the ball mill jar on a planetary ball mill for mechanical coating. The revolution speed of the ball mill is set to 500r / min and the time is set to 8 hours.

[0087] Heat treatment:

[0088] Group C-1073K: The prepared Al coated with TiC coating 2 O 3 Ceramic balls are divided equally according to Image 6 The method shown is placed in a muffle furnace for heat treatment, the heat treatment temperature is set to 1273K, the heating rate is 35K / min, and the maintenance time is 12 hours. After the furnace is cooled to room temperature, the sample is taken out to complete the sample preparation;

[0089] O-1073K group: the prepared Al coated with TiC coating 2 O 3 The ceramic balls are directly heat-treated in the atmosphere. The heat-treatment temperature is 1273K, the heating rate is 35K / min, and the maintenance time ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com