Method for characterizing microstructure of nano-structure thermal barrier coating by adopting terahertz nondestructive testing technology

A technology of thermal barrier coating and nanostructure, which is applied in the direction of measuring device, phase influence characteristic measurement, permeability/surface area analysis, etc., can solve the influence of signal peeling, nanostructure thermal barrier coating has no certain qualitative or semi-quantitative Analytical methods, long detection cycle and other issues to achieve the effect of improving accuracy, avoiding discreteness, and shortening the detection time cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

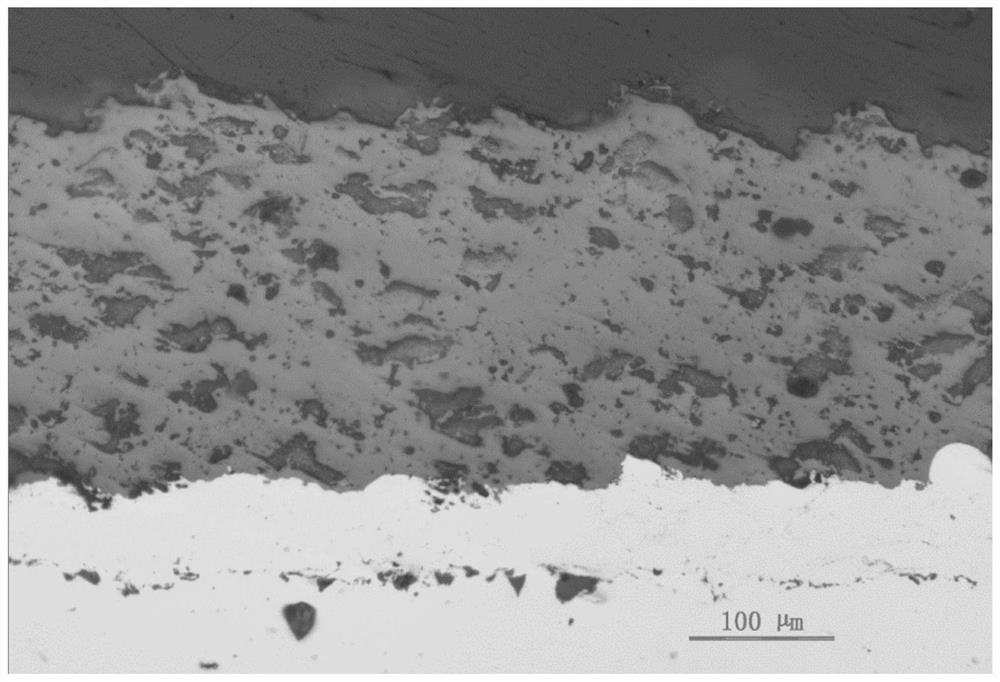

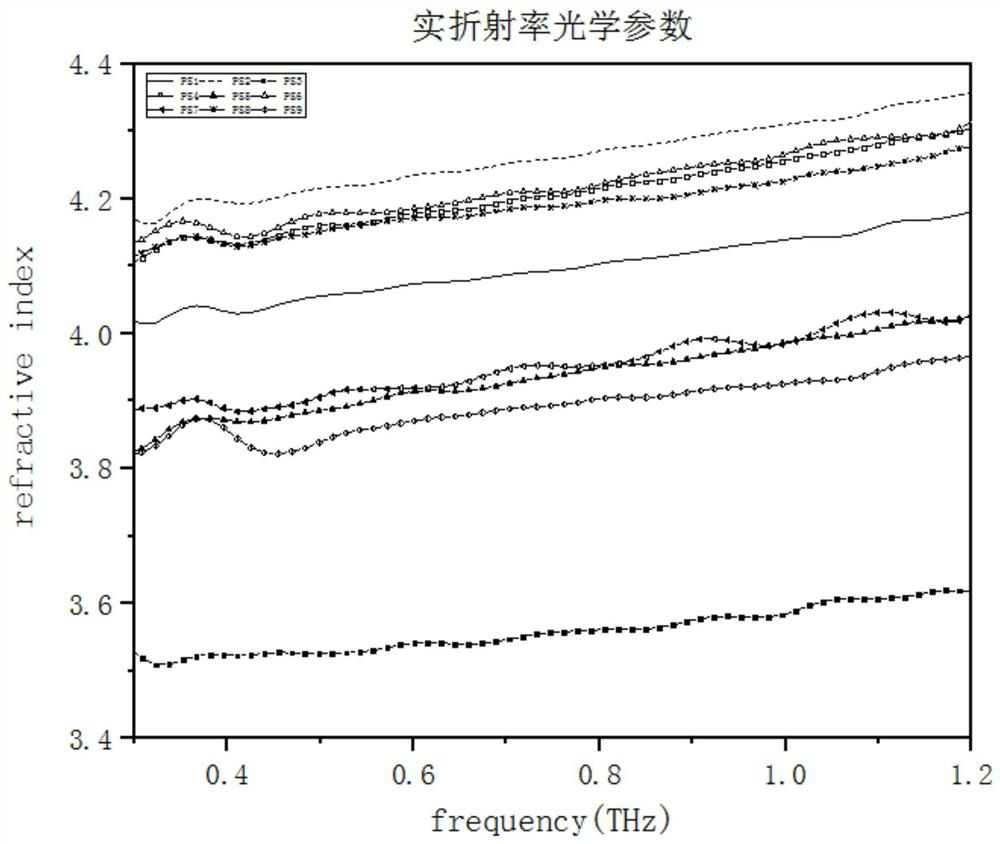

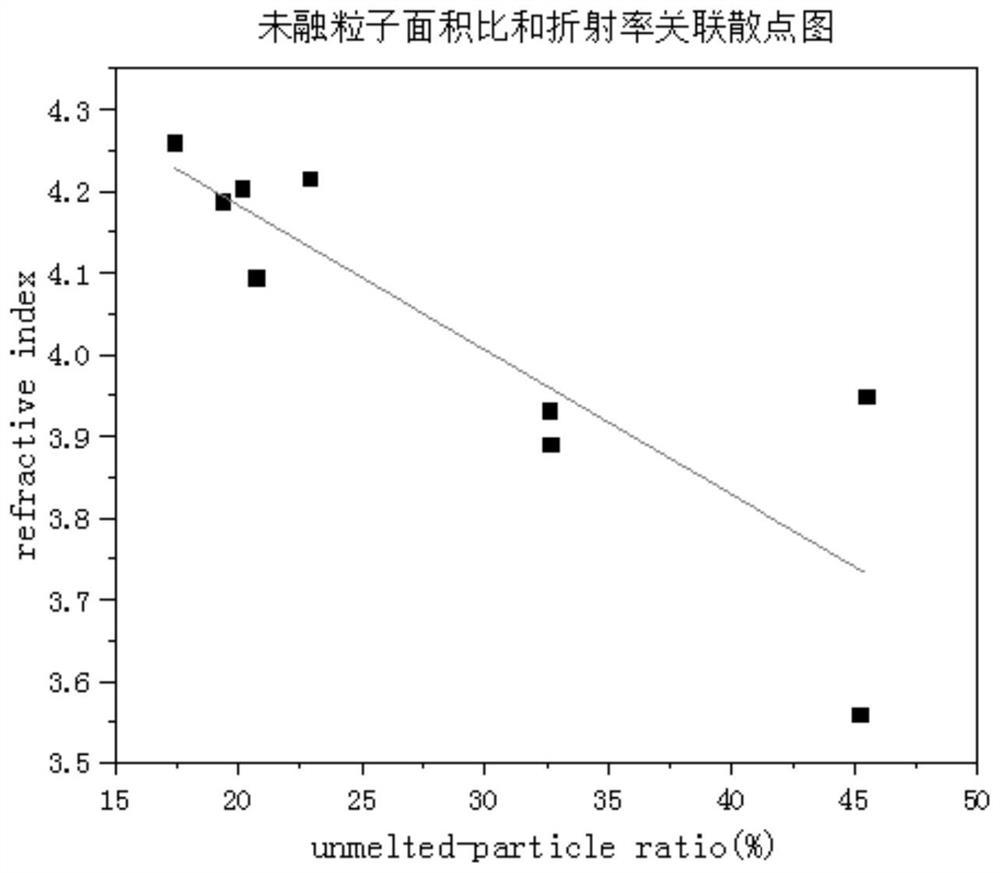

[0047] Example 1: Characterization of Unfused Particles of Nanostructured Coatings by Terahertz Nondestructive Testing Technology

[0048] This embodiment is based on the terahertz non-destructive testing method, taking the nanostructured 8YSZ type ceramic thermal barrier coating as an example, to describe the specific implementation of the terahertz characterization of the unfused particles of the nanostructured coating. The specific steps of the terahertz non-destructive testing technology to characterize the unfused particles of the nanostructure coating are as follows:

[0049] Step 1: Utilize the adjustment process to prepare a coating microstructure with a wide range of changes, and measure and analyze the unmelted particle content of the ceramic coating by a non-terahertz detection method (such as a quantitative metallographic method); preferably, based on the atmospheric plasma spraying process, 8YSZ ceramic coatings with different microstructural characteristics were ...

Embodiment 2

[0060] Example 2: Terahertz non-destructive testing technology to characterize the porosity of nanostructured coatings

[0061] This embodiment is based on the terahertz non-destructive testing method, taking the nanostructured 8YSZ type ceramic thermal barrier coating as an example, to describe the specific implementation of the terahertz characterization of the porosity of the nanostructured coating. The specific steps of the terahertz method for characterizing the porosity of nanostructured coatings are as follows:

[0062] Step 1: Use the adjustment process to prepare a wide range of coating microstructures, and measure and analyze the porosity of the ceramic coatings by quantitative metallography; preferably, 8YSZ ceramic coatings with different microstructural characteristics can be prepared based on the atmospheric plasma spraying process.

[0063] Specifically, relevant image processing methods and quantitative metallographic methods can be used to perform multi-group ...

Embodiment 3

[0073] Example 3: Characterization of Porosity and Unfused Particles of Nanostructured Coatings by Terahertz Nondestructive Testing Technology

[0074] This embodiment is based on the terahertz non-destructive testing method, taking the nanostructured 8YSZ type ceramic thermal barrier coating as an example, to describe the specific implementation of the terahertz characterization of the porosity of the nanostructured coating and the unfused particles. The specific steps of the terahertz non-destructive testing technology to characterize the porosity and unfused particles of the nanostructured coating are as follows:

[0075] Step 1: Utilize the adjustment process to prepare a coating microstructure with a wide range of changes, and measure and analyze the porosity and unfused particle content of the ceramic coating (preferably represented by the area ratio of unfused particles) by quantitative metallographic method; preferably, based on atmospheric plasma Spraying process to p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com