Coating preparation method for realizing high-efficiency operation of PS-PVD equipment

A PS-PVD, high-efficiency technology, applied in coating, metal material coating process, superimposed layer plating, etc., can solve the problems of high coating preparation cost, low plasma jet usage rate, etc., and achieve sufficient gasification. , The effect of reducing the liquid phase and unmelted particles and increasing the heating capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

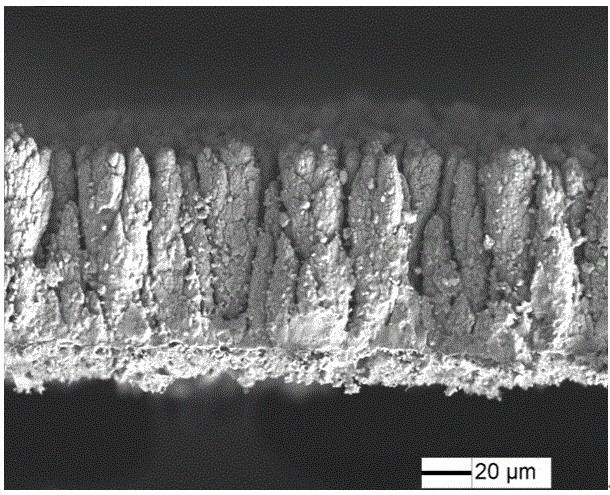

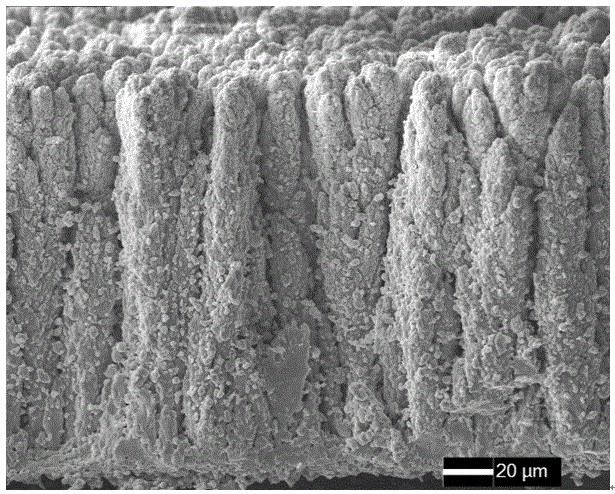

[0038] Using the method disclosed in the present invention, on a high-purity graphite substrate of 200 mm × 200 mm × 5 mm, the vacuum degree of the vacuum chamber, the total power of PS-PVD equipment spraying, and the spraying current are adjusted to obtain a plasma of 50-100 mm jet to prepare YSZ coating and analyze jet utilization, the specific process parameters used are as follows:

[0039] (1) Start the PS-PVD equipment, assemble the sprayed workpiece, and close the vacuum chamber;

[0040] (2) Vacuum until the pressure of the vacuum chamber is 50mbar;

[0041] (3) Adjust the spraying power to 70 kW and the spraying current to 1000A;

[0042] (4) Open the working gas valve and strike the arc. After the arc is stable, gradually adjust the gas flow to the specified gas flow Ar: 20L / min, He: 40L / min, H 2 : 10L / min, N 2 : 10L / min;

[0043] (5) Adjust the rotational speed of the workpiece to 10 rpm, use the plasma jet to preheat the blades, and detect the substrate tempera...

Embodiment 2

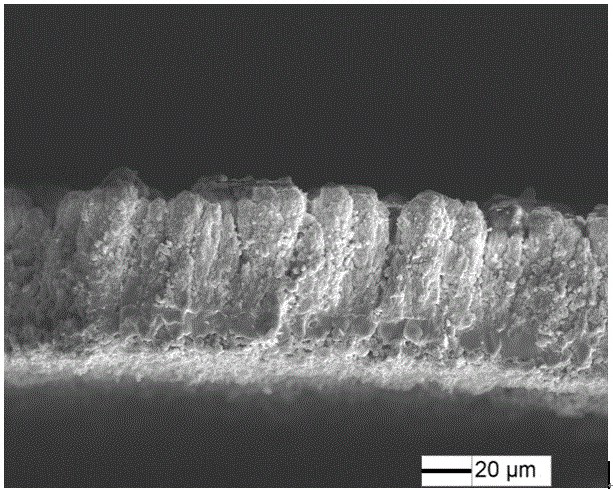

[0049] Using PS-PVD to spray YSZ ceramic layer on the surface of a duplex guide vane of a certain type of aero-engine, the method designed by the present invention is adopted respectively to regulate the vacuum degree of the vacuum chamber, the spraying power and the spraying current of the PS-PVD equipment To obtain a plasma jet of 50-100 mm to prepare YSZ coating and analyze the utilization rate of the jet, the parameters of the specific process steps are as follows:

[0050] (1) Start the PS-PVD equipment, assemble the spraying blades, and close the vacuum chamber;

[0051] (2) Vacuum until the pressure of the vacuum chamber is 50mbar;

[0052] (3) Adjust the spraying power to 70kW and the spraying current to 1000A;

[0053] (4) Open the working gas valve and strike the arc. After the arc is stable, gradually adjust the gas flow to the specified gas flow Ar: 20L / min, He: 40L / min, H 2 : 10L / min, N 2 : 10L / min;

[0054] (5) The speed of the blade is set to 10rpm, the blad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com