A method for improving microstructure of coating

A microstructure and coating technology, which is applied in coatings, devices for coating liquids on surfaces, pretreatment of surfaces, etc., can solve problems such as difficulty in exerting the inherent excellent properties of coating materials, low bonding strength, and coating failure , to achieve the effects of decreased porosity, improved coating performance, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

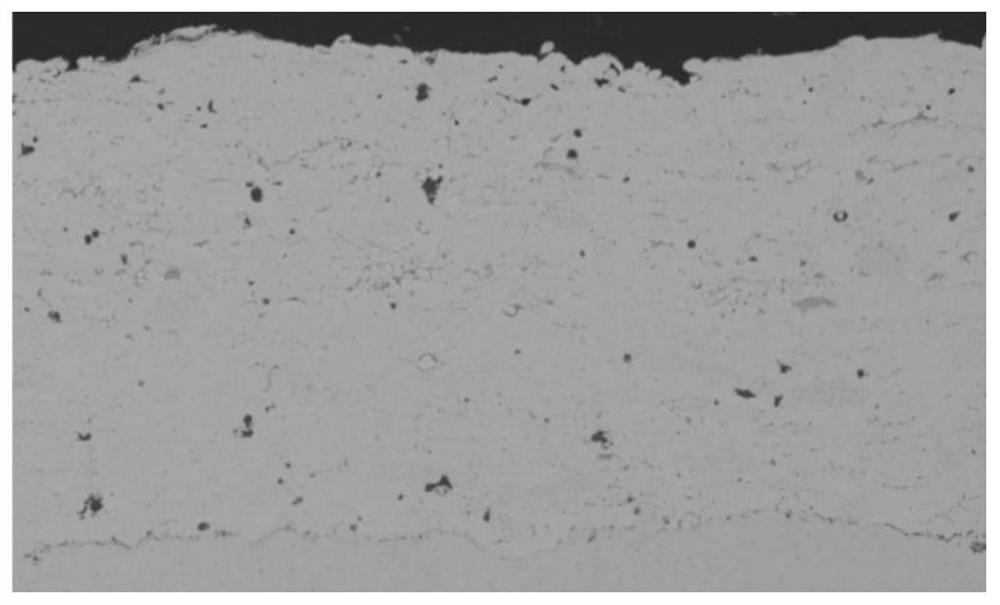

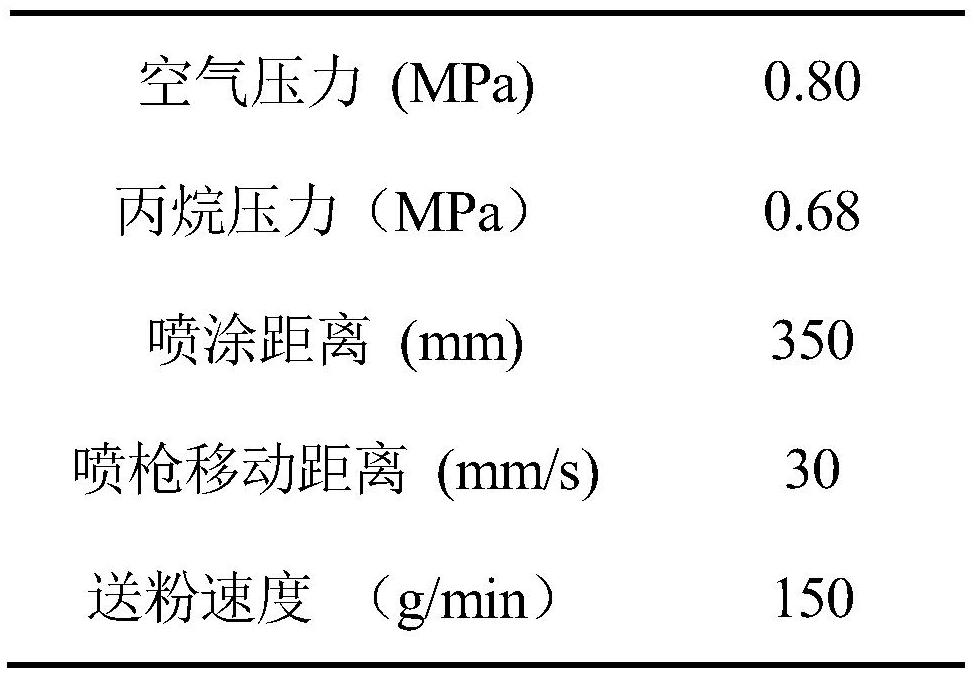

Embodiment 1

[0031] Aerosolized spherical Inconel powder was used as spray powder (AMPERIT380, HC Starck GmbH), with a particle size of 15-45 μm. TP347H heat-resistant steel (1Cr19Ni11Nb) was used as the substrate, and 16-mesh white corundum sand was used for sandblasting before spraying under the condition of compressed air pressure of 0.8MPa. Using M3 TM The -type HVAF spraying system (Uniquecoat, USA) prepared the coating under the parameters shown in Table 1. Before spraying, preheat the substrate to 350°C and start spraying the coating. During the spraying process, the substrate remains heated at 350°C. After spraying one layer on the surface of the substrate, laser shock strengthening is carried out on the surface of the deposited coating. The parameters of laser shock strengthening are: the laser power density is 0.6GW / cm 2 , the pulse frequency is 5Hz. After the laser shock, continue to the next spraying and laser shock strengthening treatment, and the parameters of each sprayin...

Embodiment 2

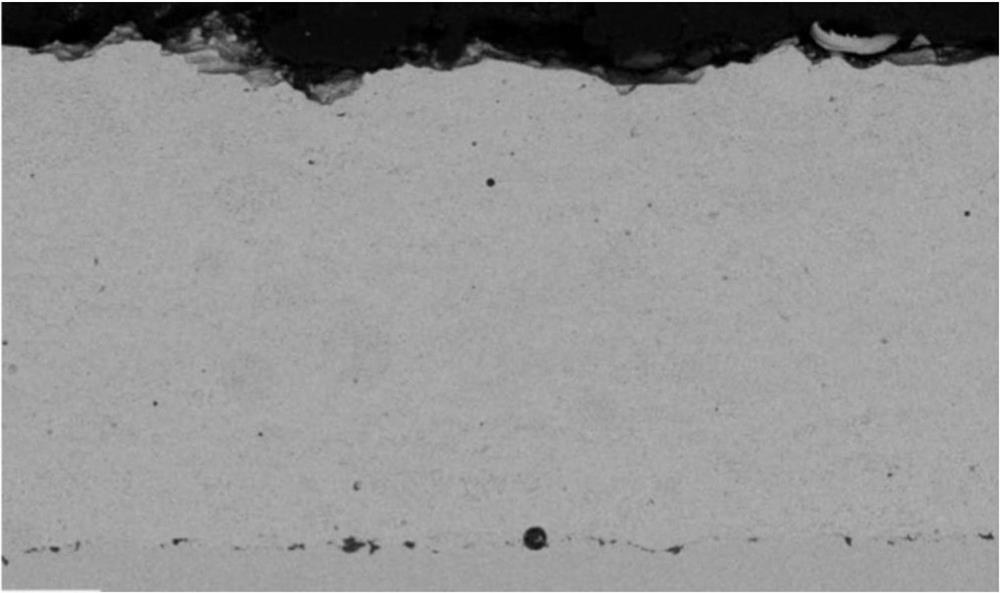

[0035] TP347H heat-resistant steel (1Cr19Ni11Nb) was used as the substrate, and 16-mesh white corundum sand was used for sandblasting before spraying under the condition of compressed air pressure of 0.8MPa. The smelted and crushed 8YSZ ceramic powder was selected, and the ceramic coating was prepared by using the APS spraying technology under the spraying parameter conditions shown in Table 2. Before spraying, preheat the substrate to 700°C and start spraying the coating. During the spraying process, the substrate remains heated at 700°C. After the surface of the substrate is sprayed once, the surface of the deposited coating is shot peened, and the shot peening is made of ceramic pellets (the chemical composition of which is roughly 67% ZrO 2 , 31% SiO 2 and 2% Al 2 o 3 The main inclusions are made by melting, atomization, drying, round selection, and screening), and the working pressure of ceramic pellets is 0.5MPa. After shot peening, continue to the next spraying and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com