High hardness gradient enhanced cold roll and preparation method for surface laser cladding coating thereof

A technology of laser cladding and cold roll, which is applied in the direction of coating, roll, metal rolling, etc., can solve the problems of difficult roll overall strengthening, cold roll use requirements, and difficult to achieve mechanical properties, so as to achieve no crack pores and improve toughness , the effect of reducing crack sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

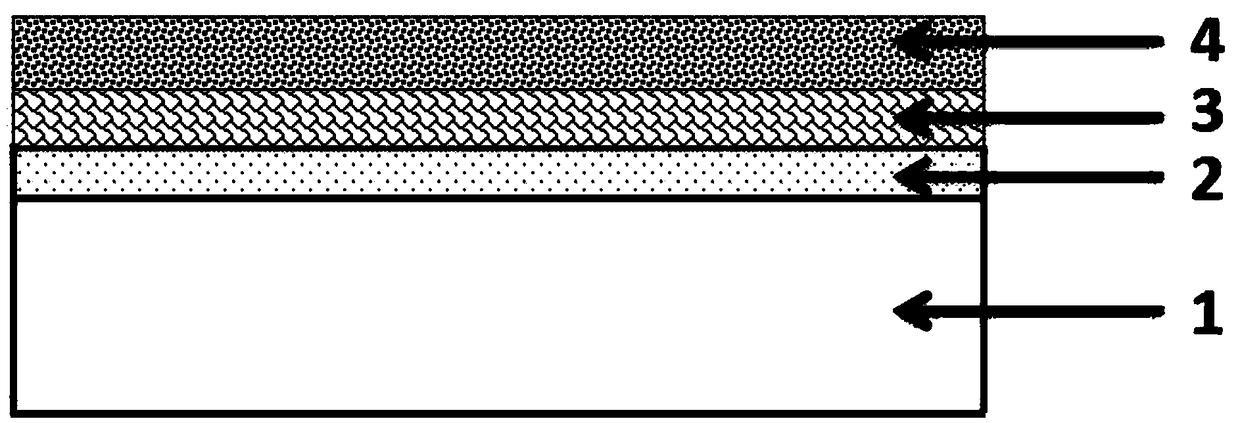

[0032] like figure 1 as shown, figure 1 It is a structural schematic diagram of the cross-section of the high-hardness gradient enhanced cold roll of the present invention; the high-hardness gradient enhanced cold roll of the present invention includes a cold roll base 1 and a surface laser cladding coating, and the surface laser cladding coating is set to include The gradient structure of the laser cladding primer layer 2, the laser cladding transition layer 3 and the laser cladding working layer 4.

[0033] Wherein, the laser cladding primer layer 2 is formed by laser cladding of self-fluxing iron-based alloy powder onto the roll body and roll neck surface of the cold rolling roll base 1; the particle size of the self-fluxing iron-based alloy powder is 100 Mesh to 270 mesh, the alloy mass percentage composition is: C: 0.2%, Cr: 17%, B: 1.7%, Si: 1.4%, Mo: 2%, and the rest is Fe. The thickness of the laser cladding primer layer 2 is generally set at 1 mm to 1.5 mm.

[0034...

Embodiment 2

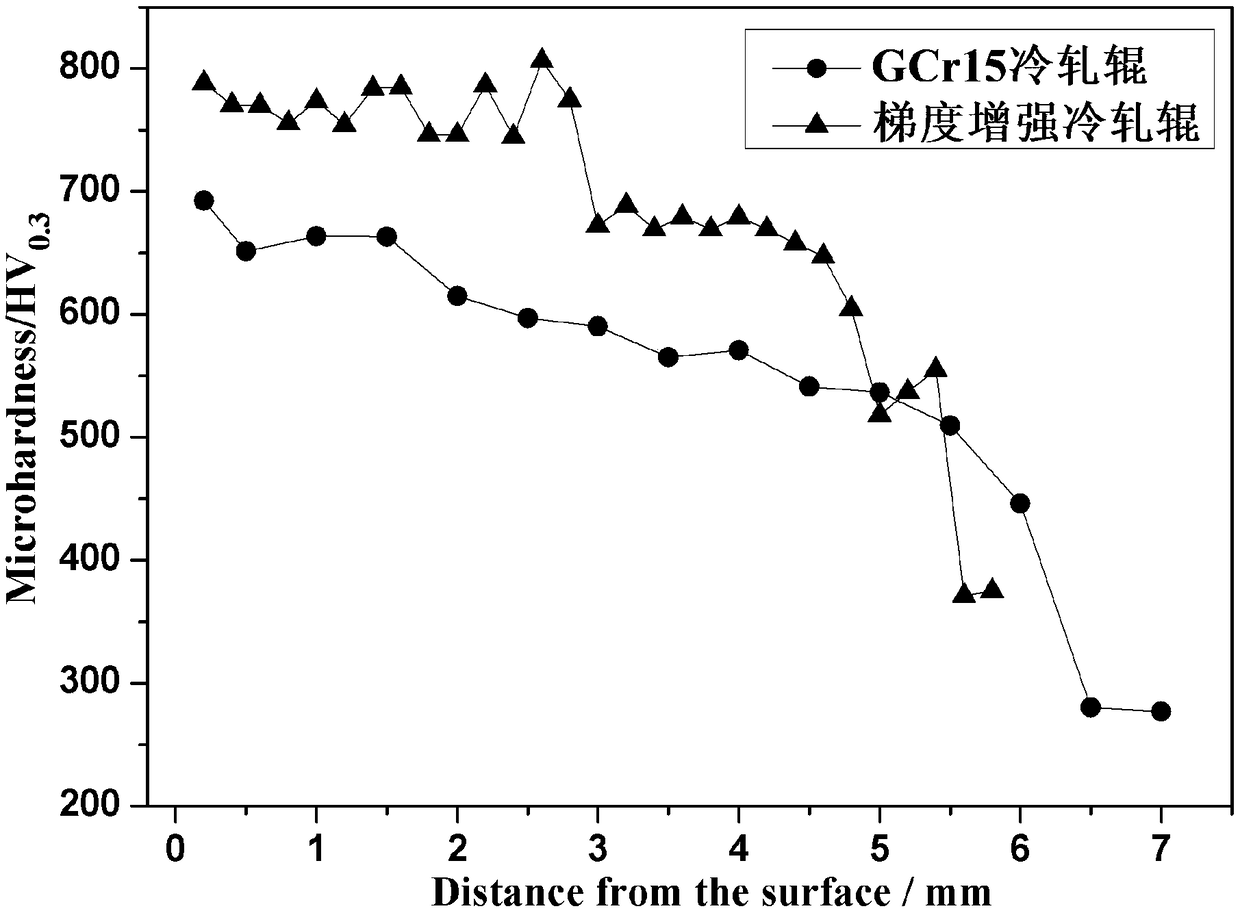

[0040] In this embodiment, the material of the cold roll base 1 is GCr15 high-carbon chromium bearing steel. GCr15 high-carbon chromium bearing steel has high hardenability, and high and uniform hardness can be obtained after heat treatment, but the weldability is poor. Sensitive to white spot formation. In the existing field, the GCr15 cold rolls used for rolling 6mm strips have a very short online service life, and the failure of the rolls causes a lot of waste. At the same time, the shutdown of production and replacement of rolls greatly reduces the production efficiency of the enterprise. The GCr15 cold rolling roll is strengthened by laser cladding through the preparation method of the invention to form a laser cladding coating, so as to improve the performance of the GCr15 cold rolling roll and prolong the service life.

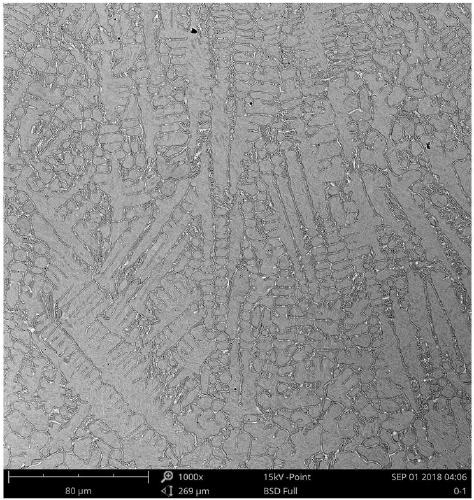

[0041] Specifically, in the present embodiment, the preparation method of the crack-free laser cladding coating on the surface of the GCr15 cold roll i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com