Control method for thermal barrier coating porosity

A control method and technology of thermal barrier coating, applied in coating, metal material coating process, air transportation, etc., can solve problems such as difficult to meet, long cycle, difficult to guarantee coating quality stability, etc., and achieve broad application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The method for controlling the porosity of the thermal barrier coating of the present invention comprises the following steps:

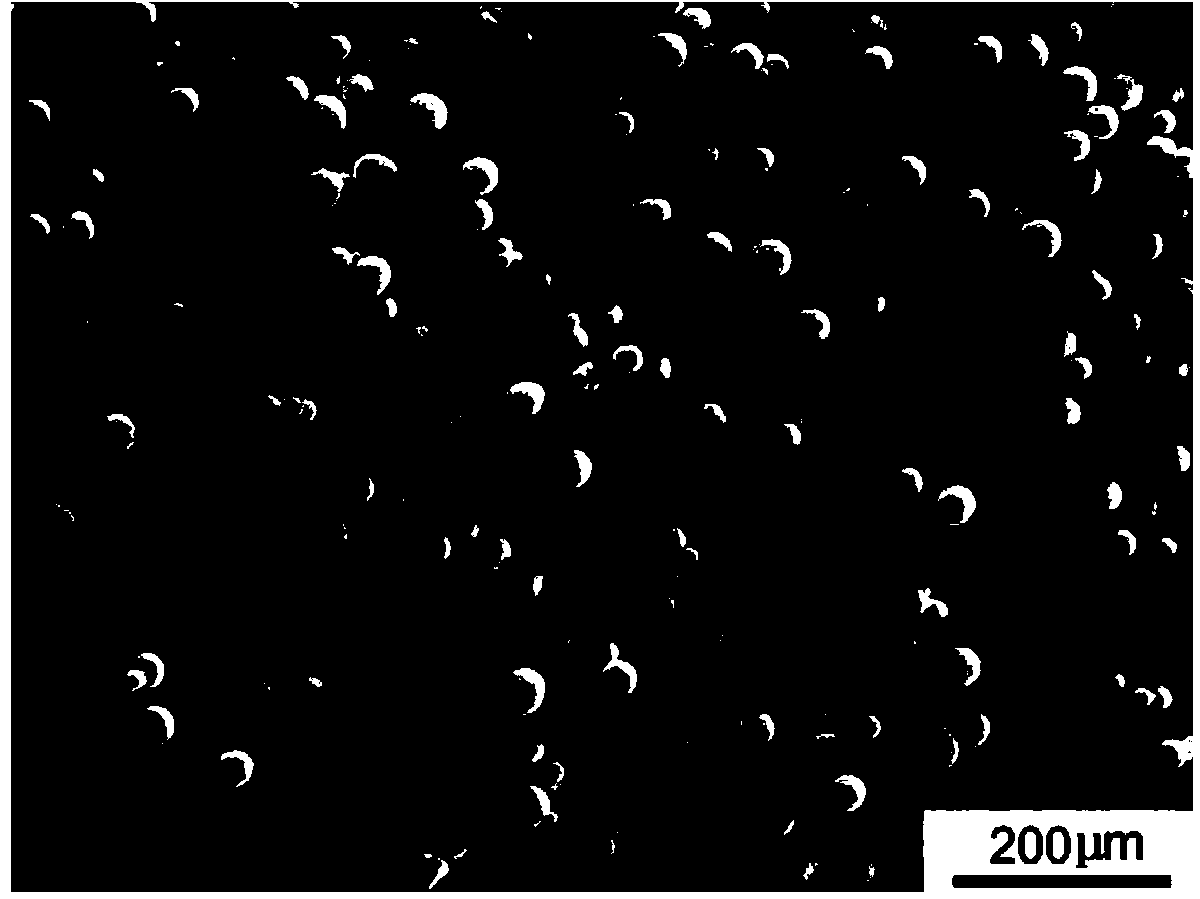

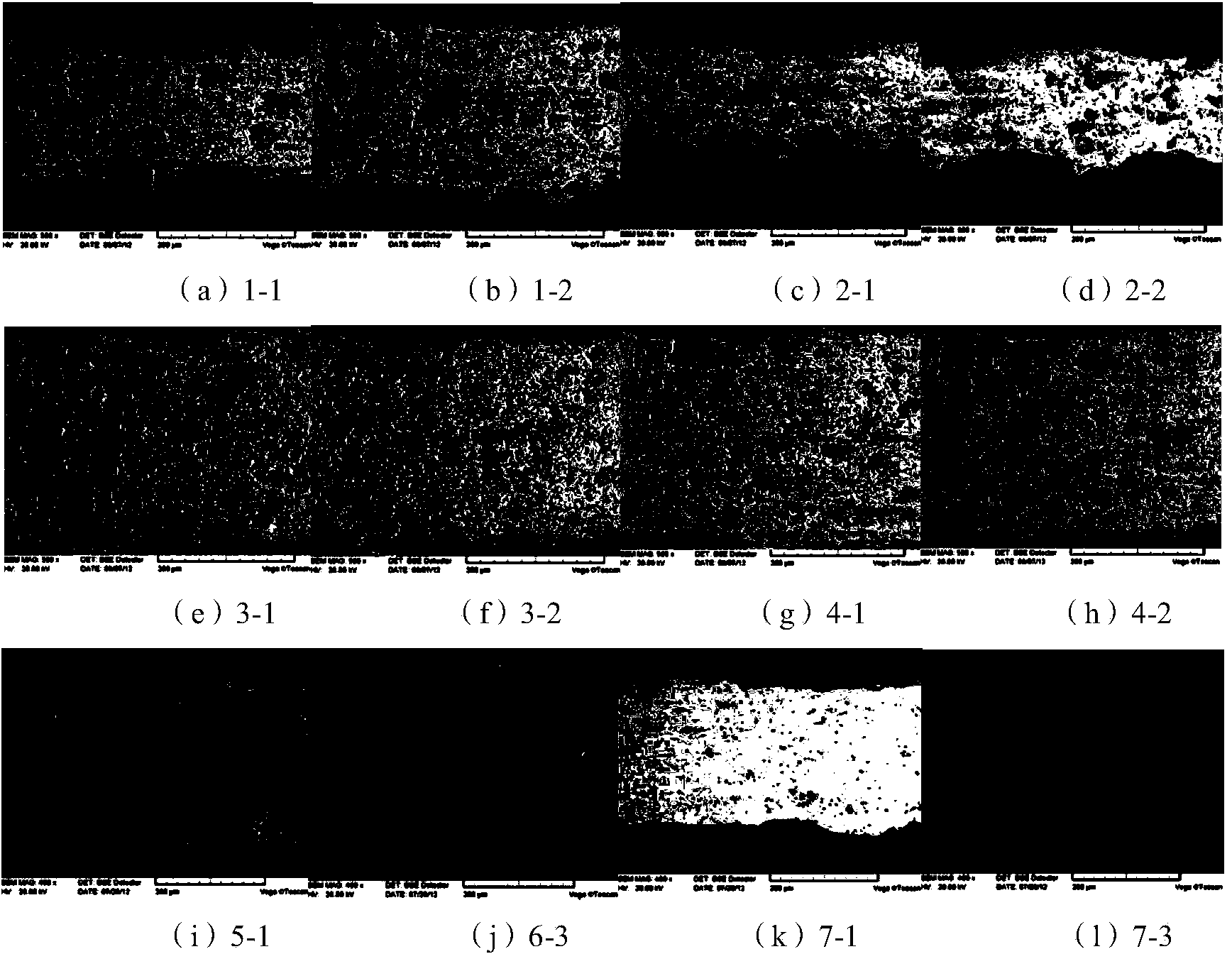

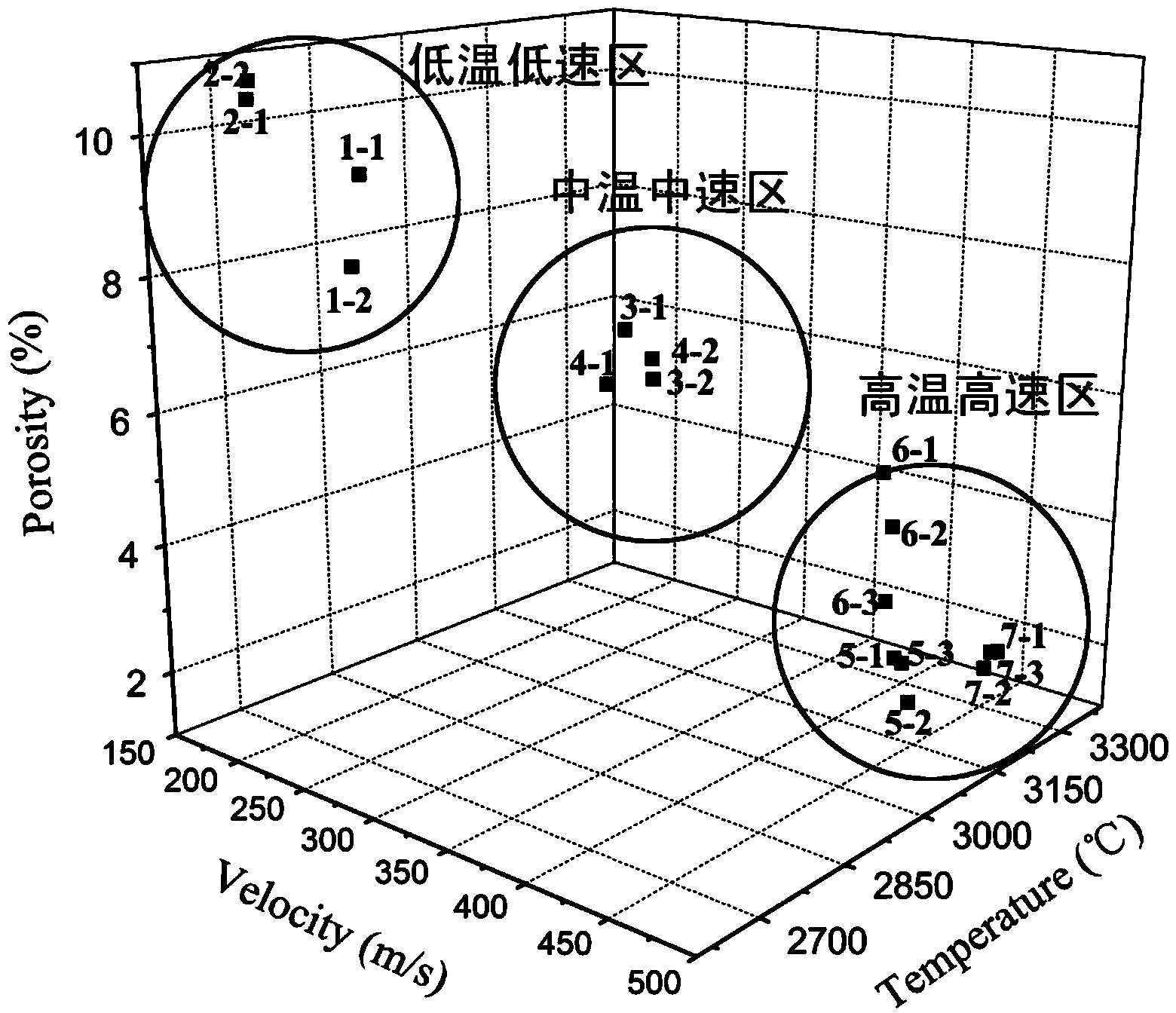

[0020] (1) use figure 1 The YSZ raw material (25-90 μm) stabilized by the yttrium oxide part shown was sprayed in seven examples (17 samples) by using the ordinary plasma spraying system APS (relatively low temperature) or the supersonic plasma spraying system SAPS (relatively high temperature) Coating, during the spraying process, the back of the substrate is cooled by compressed air, the surface temperature of the sample is controlled at 150±20°C during spraying (measured by an infrared measuring instrument), and the process parameters are adjusted. Current range: 440-808A, voltage range: 72 -147V, main gas (argon) flow range: 35-70SLPM, auxiliary gas (hydrogen) flow rate 16.6-24.3SLPM, powder feeding volume 35-40g min -1 , Spray distance 70 ~ 100mm (Table 1). The Spray Watch2i temperature measurement and speed measurement system developed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com