A kind of hoisting positioning device and method for prefabricated cement concrete paving slab

A cement concrete and positioning device technology, which is applied in roads, buildings, climate change adaptation, etc., can solve the problems of difficult construction adjustment, complex positioning, and affecting construction progress, and achieve the effect of quality stability and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

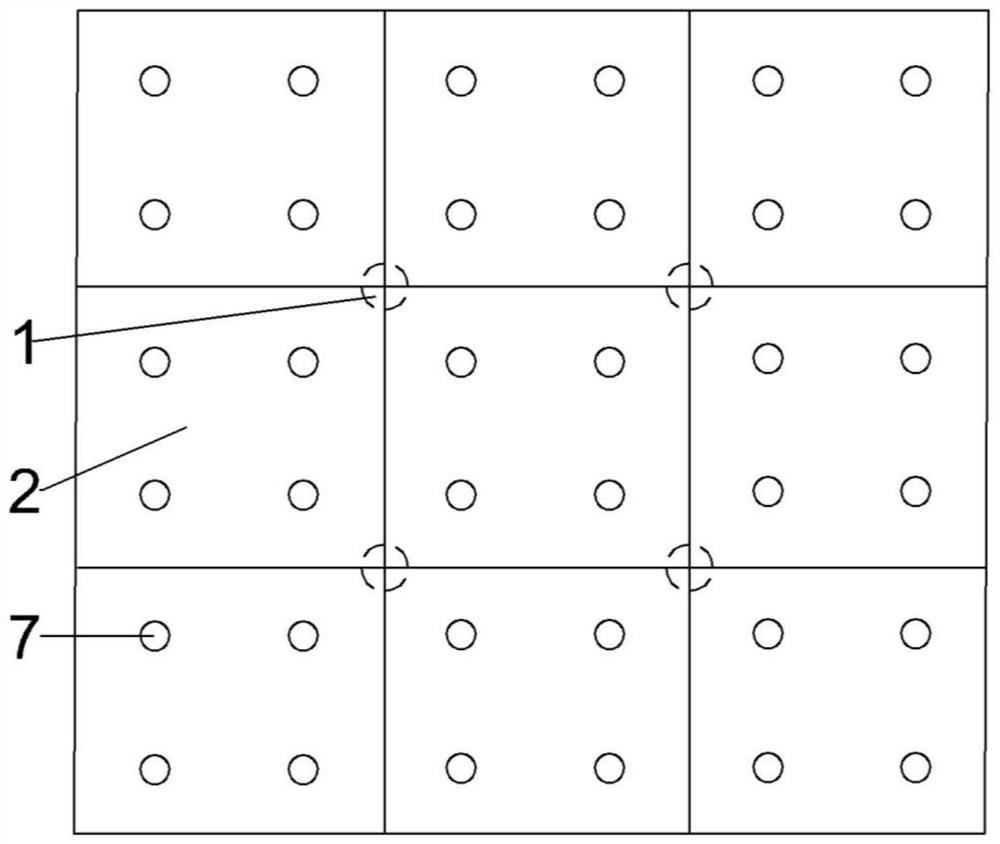

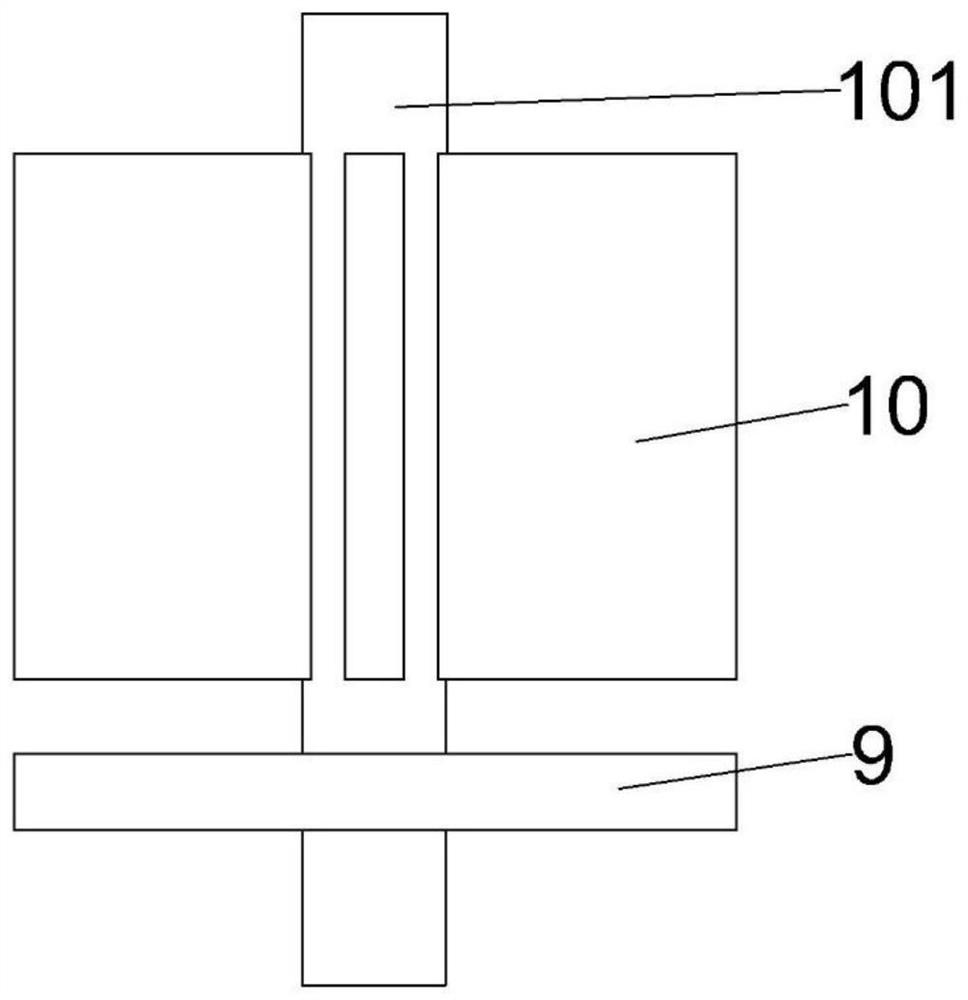

[0041] refer to Figure 1-4As shown, the present invention provides a hoisting and positioning device for prefabricated cement concrete paving slabs, comprising several positioning columns 1 and supporting platforms 5, the positioning columns 1 and the supporting platforms 5 are respectively connected on the roadbed, and the concrete paving slabs 2 are placed Between several positioning columns 1, four positioning plates 10 are arranged at equal intervals in the outer circumferential direction of the positioning columns 1, and the four positioning plates 10 are arranged vertically. A guide bracket 8 is inserted and connected, and the concrete deck board 2 is placed above several supporting platforms 5 .

[0042] First determine the position of the positioning plate 10, the positioning plate 10 is the main reference point of the entire road construction; the positioning plate 10 can locate the concrete deck 2; the support platform 5 is mainly used to carry the concrete deck 2 b...

Embodiment 2

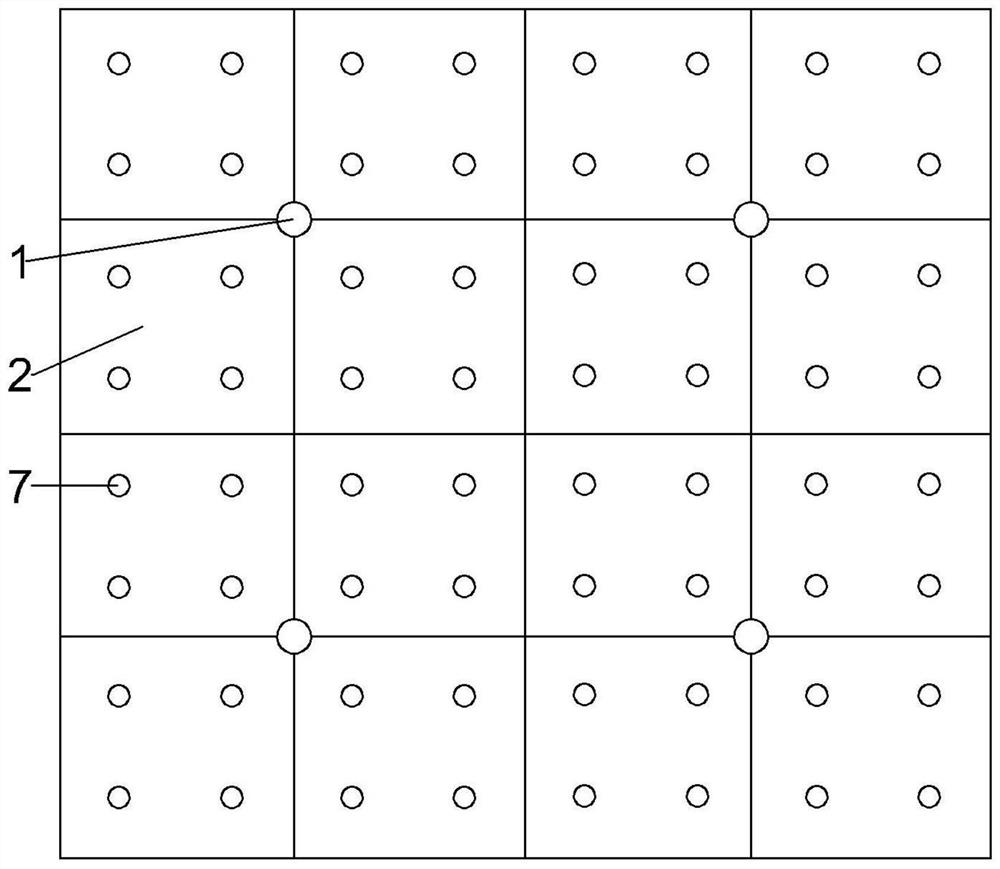

[0045] refer to Figure 3-13 As shown, the difference between the positioning method of this embodiment and the first embodiment is only:

[0046] The further optimized solution also includes a plurality of sealing strips 4, a plurality of sealing strips 4 are vertically crossed and fixedly connected to each other, a plurality of supporting platforms 5 are arranged on the inner side of the sealing strips 4, the sealing strips 4 and the supporting platforms 5 are respectively fixedly connected on the roadbed, and the sealing strips 4 , The top surface of the support platform 5 and the bottom surface of the concrete paving panel 2 are set at the same height. The sealing strip 4 is mainly used to keep the mud under the concrete pavement 2 during the grouting process after the concrete paving plate 2 is laid for the construction road without leakage. After the mud is hardened, a good bonding effect is produced.

[0047] To further optimize the solution, the positioning column 1 i...

Embodiment 3

[0070] refer to Figure 4As shown, the difference between the positioning method of this embodiment and the second embodiment is only:

[0071] If the roadbed is soil ground, first use a measuring instrument to determine the positioning point; in steps 2 to 4, the cement concrete, positioning datum, sealing strip 4 and support platform 5 are fixedly connected by steel bars (not shown in the figure) to form a steel weave. network. The alignment process and the grouting process are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com