Heating device for preparing high-quality aluminum nitride templates on large scale and preparation method

A heating device and aluminum nitride technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problem that aluminum nitride templates cannot meet the needs of low cost, high quality, high uniformity, and mass production. , affecting epitaxial growth and other issues, to achieve the effect of promoting reconstruction and re-growth process, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

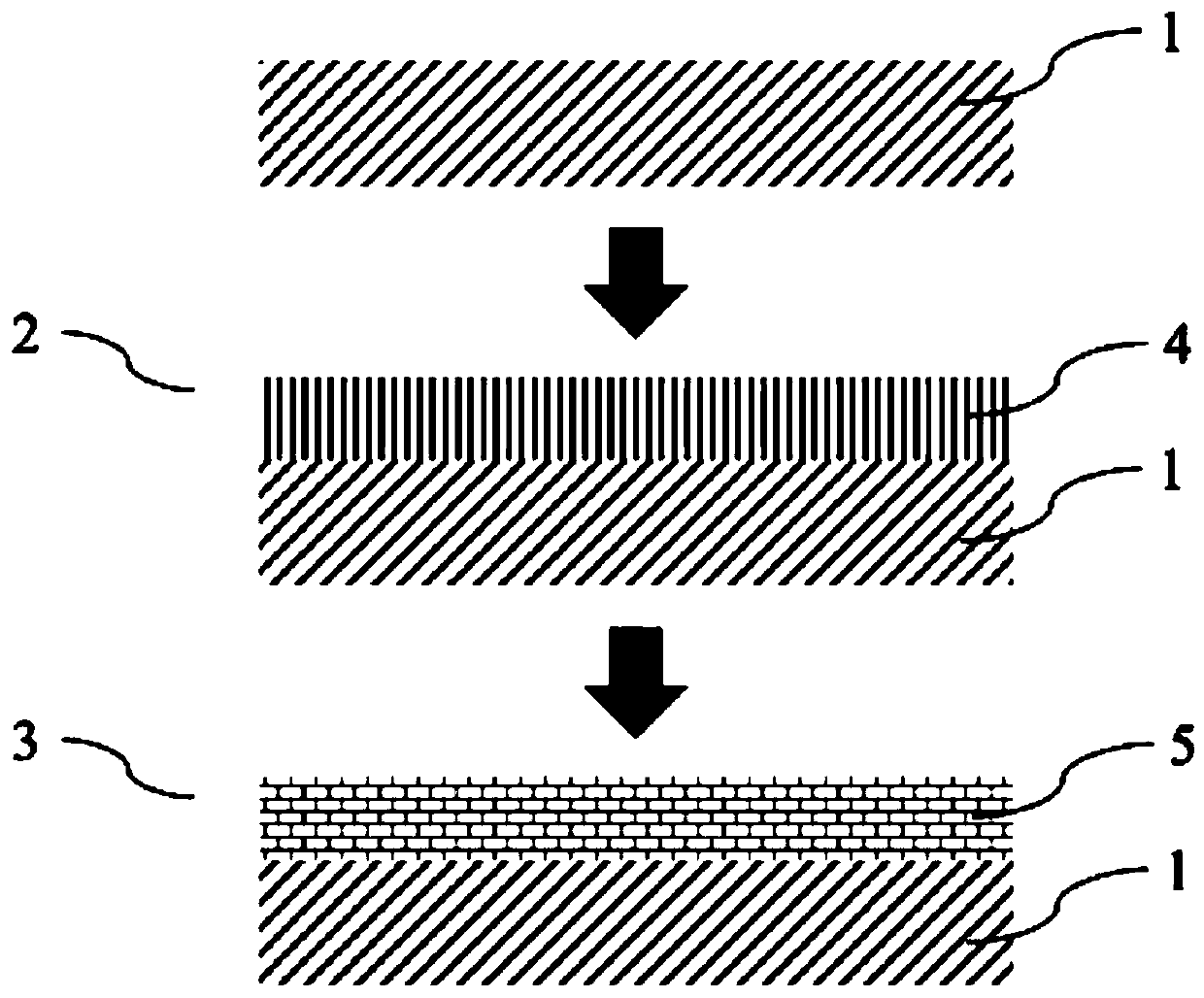

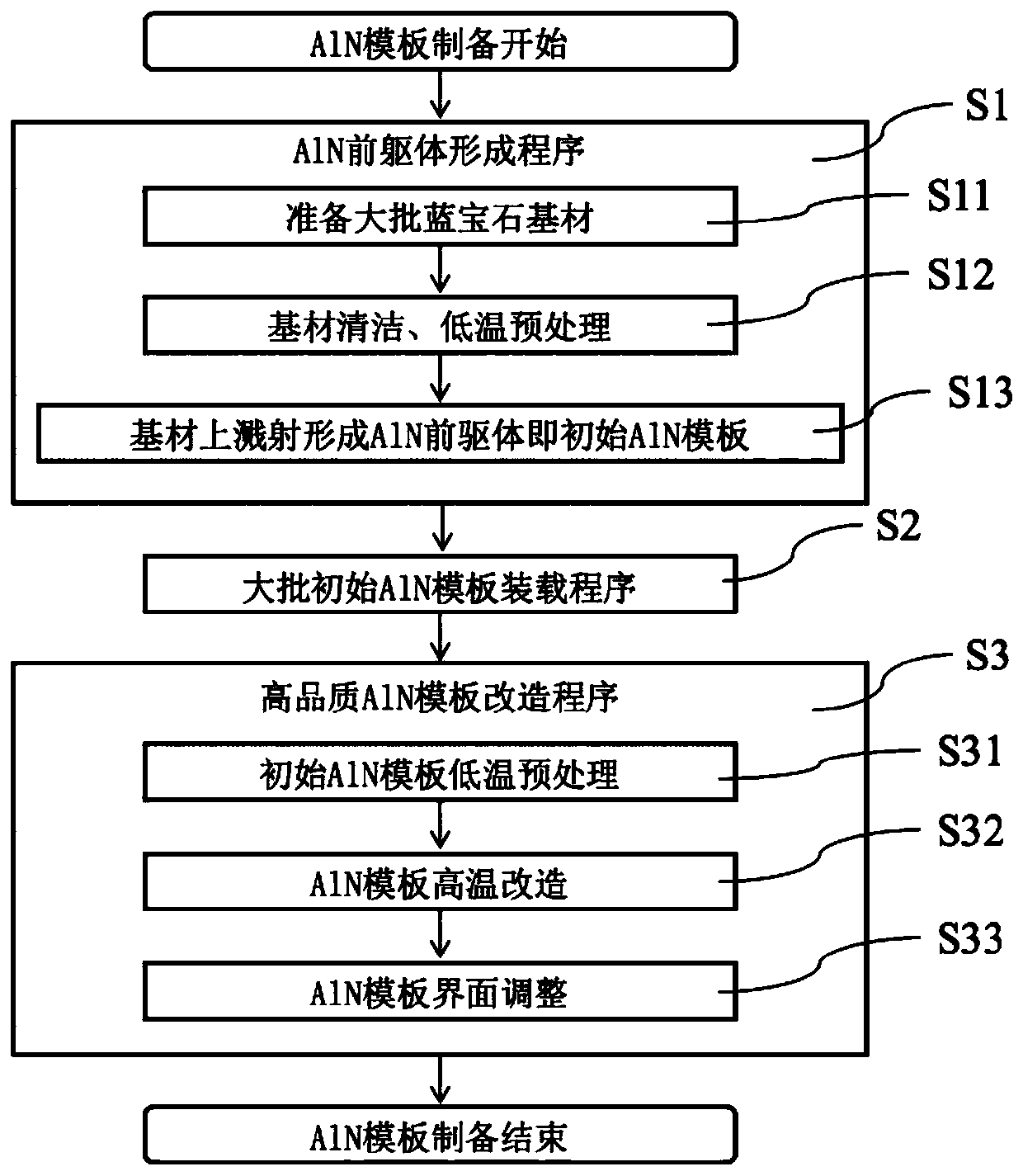

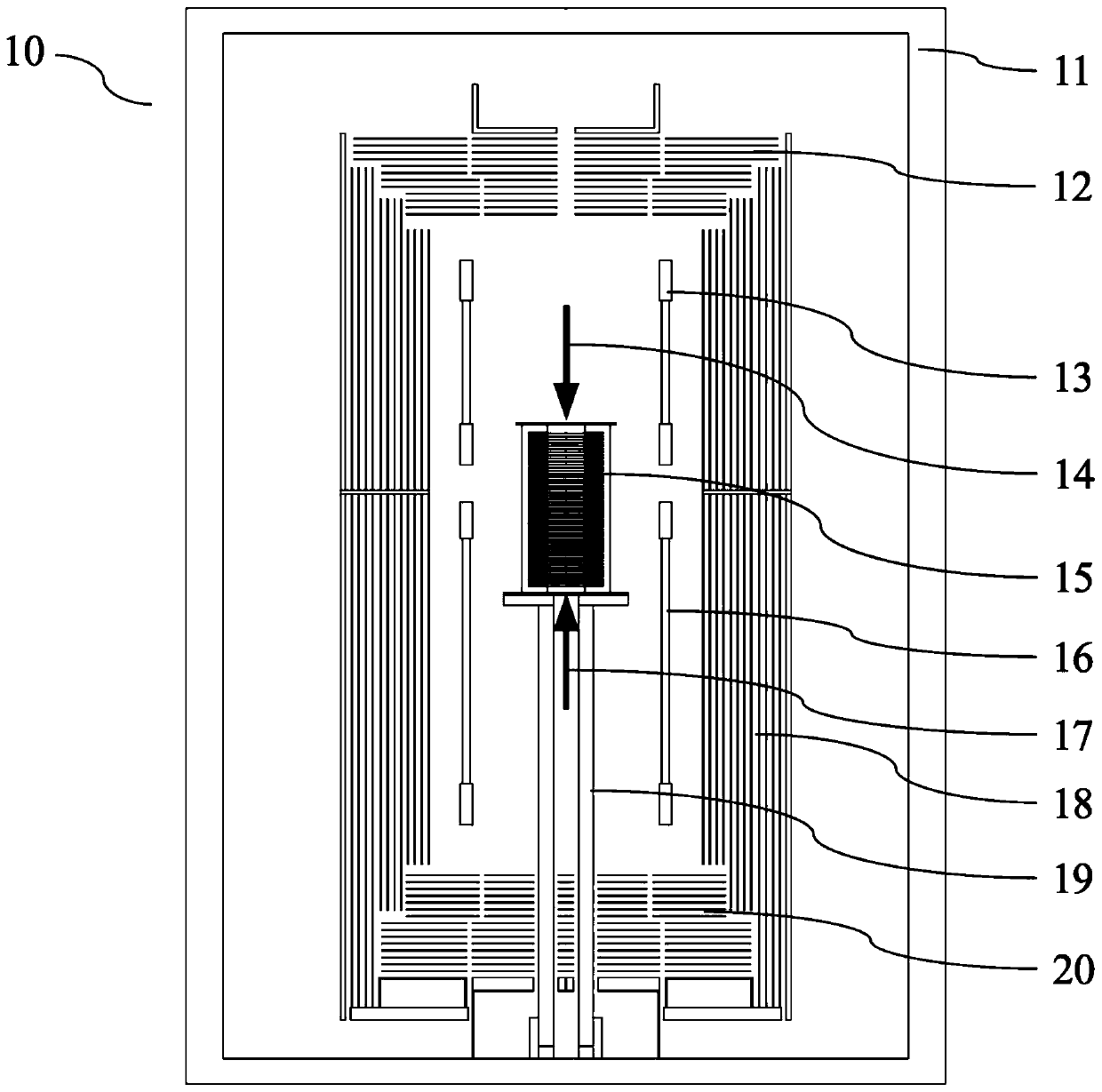

[0067] A method for preparing high-quality aluminum nitride templates in batches: mainly including the preparation of a substrate 1, the preparation of an aluminum nitride precursor 4, and the modification of an aluminum nitride template 3. In this embodiment, sapphire is used as the base material 1 , but the base material 1 is not limited to sapphire, and the base material 1 made of at least one of sapphire, silicon carbide (SiC) and aluminum nitride (AlN) is sufficient. The preparation method of the aluminum nitride precursor 4 adopts the sputtering method (sputter) in this embodiment, but the preparation method is not limited to the sputtering method, sputtering method, metal organic compound vapor phase epitaxy (MOCVD), molecular beam epitaxy One or more of (MBE), hydride vapor phase epitaxy (HVPE) can be superimposed. The transformation of aluminum nitride template 3 is through the Al, N 2 Under the mixed atmosphere, the dissociation of the aluminum nitride layer 5 on th...

Embodiment 2

[0089] This embodiment is aimed at preparing aluminum nitride templates 3 with an aluminum nitride layer 5 thicker than 1000 nm in batches. First, refer to Figure 27 and Figure 28 , the process of preparing the aluminum nitride template 3 is described. Figure 27 It is a schematic diagram of the method for preparing an aluminum nitride thin film template in this embodiment. Figure 28 its about Figure 27 Flowchart of the batch implementation process.

[0090] Compared with the process procedure ( figure 2 ), the process procedure for preparing aluminum nitride templates with an aluminum nitride film thickness greater than 1000nm in batches 3 adds an aluminum nitride film layer chemical mechanical polishing (CMP) procedure (S4) and repeated preparations that do not reach the expected film thickness. The principle is that the aluminum nitride template 3 with a film thickness of less than 1000nm can be prepared with high quality through the S1-S3 process procedure, but t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com