Preparation method of artificial graphite cathode material

An artificial graphite negative electrode and graphite crushing technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of reduced yield, increased equipment energy consumption, expensive price, etc., to achieve easy scale production, increase yield, The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

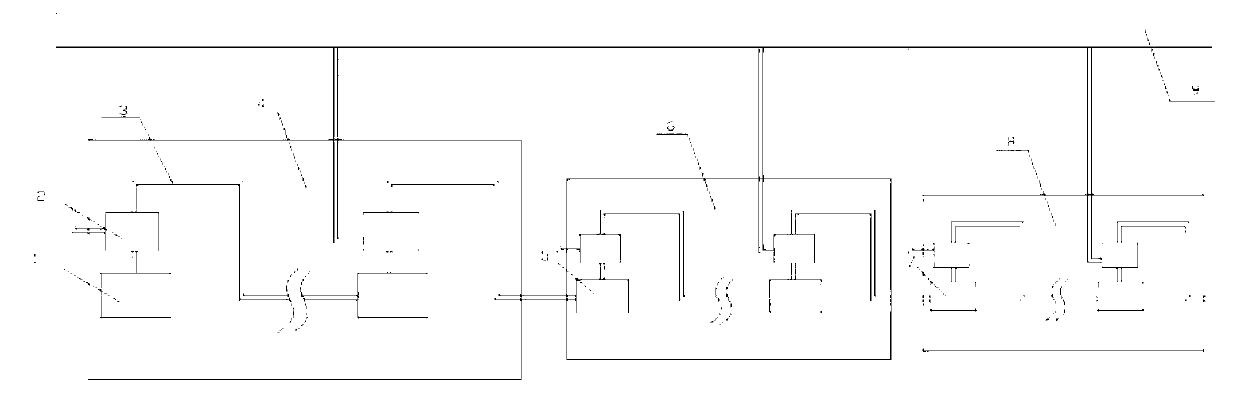

Image

Examples

Embodiment 1

[0026] Embodiment 1: a kind of preparation method of artificial graphite negative electrode material, comprises the following steps:

[0027] (1) Crush graphite with a particle size of less than 4mm and spheroidize it. After spheroidization, the median diameter of graphite powder is 15-22μm, and the specific surface area is less than 7m 2 / g, the tap density is greater than 0.85g / cm 3 ;

[0028] (2) Crush the coating material asphalt to a median diameter of 3-5 μm;

[0029] (3) Weigh 80-95 parts by weight of graphite powder in step (1), 5-20 parts by weight of asphalt micro-powder in step (2), put them in a conical mixer for rough mixing for at least 10 minutes, then discharge, and then mix the Put the materials in the mechanical fusion machine, then start the mechanical fusion machine, and fuse at a speed of 500r / min~1000r / min for 15~60min, so that the asphalt is coated on the graphite surface, and then discharge;

[0030] (4) Put the pitch-coated graphite powder in step (...

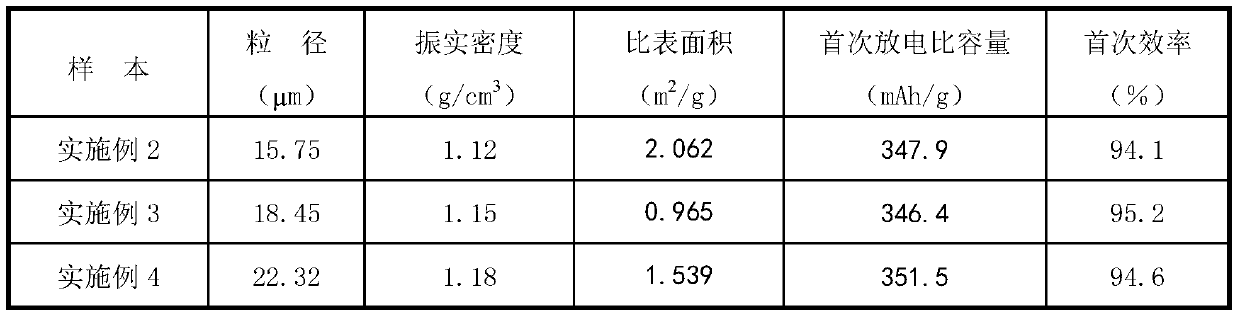

Embodiment 2

[0035] Take ultra-high-power graphite electrode powder with a particle size of less than 4mm (Fangda Carbon New Material Technology Co., Ltd.), through two 120kw air-flow vortex ultra-fine powder machines, four 90kw air-flow vortex ultra-fine powder machines, and 70kw air-flow vortex ultra-fine powder The spheroidization system composed of 4 micropowder machines in series will spheroidize it. After spheroidization, the median diameter of artificial graphite powder is 15μm, and the specific surface area is 6.4m 2 / g, tap density 0.88g / cm 3, Get 30kg of artificial graphite micropowder after spheroidization. Then high-temperature modified asphalt (Huanghua Xinnuo Lixing Coal Chemical Co., Ltd.) was pulverized by a jet mill (Weifang Zhengyuan Powder Equipment Co., Ltd.), with a median diameter of 4.5 μm, and 1.5 kg of pulverized asphalt powder was taken. Put the above-mentioned artificial graphite micropowder and asphalt micropowder in a conical mixer (Wuxi Qingxin Powder Equipme...

Embodiment 3

[0037] Take ultra-high-power graphite joint pieces with a particle size of less than 4mm (Fangda Carbon New Material Technology Co., Ltd.), through 4 sets of 100kw air-flow vortex ultra-fine powder machines, 4 sets of 70kw air-flow vortex ultra-fine powder machines, and 50kw air-flow vortex ultra-fine powder The automatic spheroidization system composed of 4 micropowder machines in series will spheroidize it. After spheroidization, the median diameter of artificial graphite micropowder is 18μm, and the specific surface area is 5.6m 2 / g, tap density 0.90g / cm 3 , Get 30kg of artificial graphite micropowder after spheroidization. Then the mesophase pitch (Fangda Carbon New Material Technology Co., Ltd.) was pulverized with a jet mill (Weifang Zhengyuan Powder Equipment Co., Ltd.), with a median diameter of 3.4 μm, and 7.5 kg of pitch fine powder was taken. Put the above-mentioned artificial graphite micropowder and asphalt micropowder in a conical mixer (Wuxi Qingxin Powder Equ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com