Carbon-nanometer-tube-based magnetic nanometer composite material and manufacturing method thereof

A carbon nanotube and magnetic nanotechnology, applied in the field of carbon nanotube-based magnetic nanocomposite materials and their preparation, can solve the problems of negative environmental impact, influence performance, weaken related performance, etc., and achieve low cost, regular size and dispersibility. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

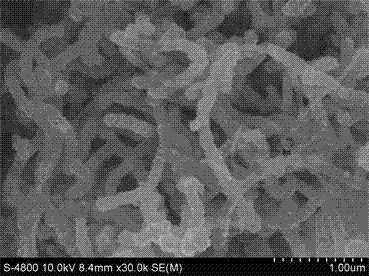

[0033] Example 1 Preparation of Ni / CNx Nanocomposite

[0034] (1), nitrogen-doped carbon nanotube material (CN X ) preparation:

[0035] 10 g of soluble iron salt FeCl 3Dissolved in deionized water; then added dropwise to 10 g of treated NaY molecular sieves for impregnation, after completion, dried at 100-150°C for 8 hours, and then roasted at 850°C for 2 hours to obtain iron-containing carbon nano Control the spare catalyst; then use ethylenediamine as the carbon source and nitrogen source, under the action of the prepared catalyst, go through chemical vapor deposition (CVD) at a flow rate of 20mL / min and set the temperature at 650~1000℃, constant temperature 0.5~ 5 hours, obtain nitrogen-doped carbon nanotube material (CN X );

[0036] (2) Preparation of Ni / CNx nanocomposites

[0037] ① The nitrogen-doped carbon nanotubes CN prepared in step (1) X Stir in HF solution for 30min to remove the residual molecular sieve;

[0038] ② The nitrogen-doped carbon nanotube CN...

Embodiment 2

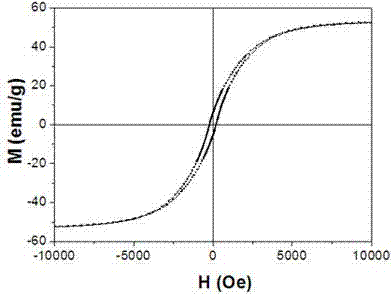

[0042] The soluble iron salt FeCl in the step (1) of embodiment 1 3 With Fe(NO 3 ) 3 , Instead, other steps and conditions are the same as in Example 1, and Ni / CNx nanocomposites can also be obtained. The M-H diagram of the Ni / CNx nanocomposite is shown in figure 2 shown. It can be seen that when the applied magnetic field is about 8000 Oe, it basically reaches saturation, and the saturation magnetization ( M s ) higher than 50 emu / g slightly lower than the bulk structure of pure phase metallic Ni. .

Embodiment 3

[0044] The ethylenediamine in the step (1) of Example 1 was replaced with dimethylamine, and the other steps and conditions were the same as in Example 1, and the Ni / CNx nanocomposite material could also be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com