Cd MOF (metal-organic framework) material and preparation method thereof

An organic framework, cadmium metal technology, applied in the direction of organic chemistry methods, cadmium organic compounds, 2/12 group organic compounds without C-metal bonds, etc., can solve the problem of losing high specific surface area and structural integrity, and unstable MOFs materials , easily attacked by water molecules, etc., to achieve good selective adsorption, easy to obtain, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

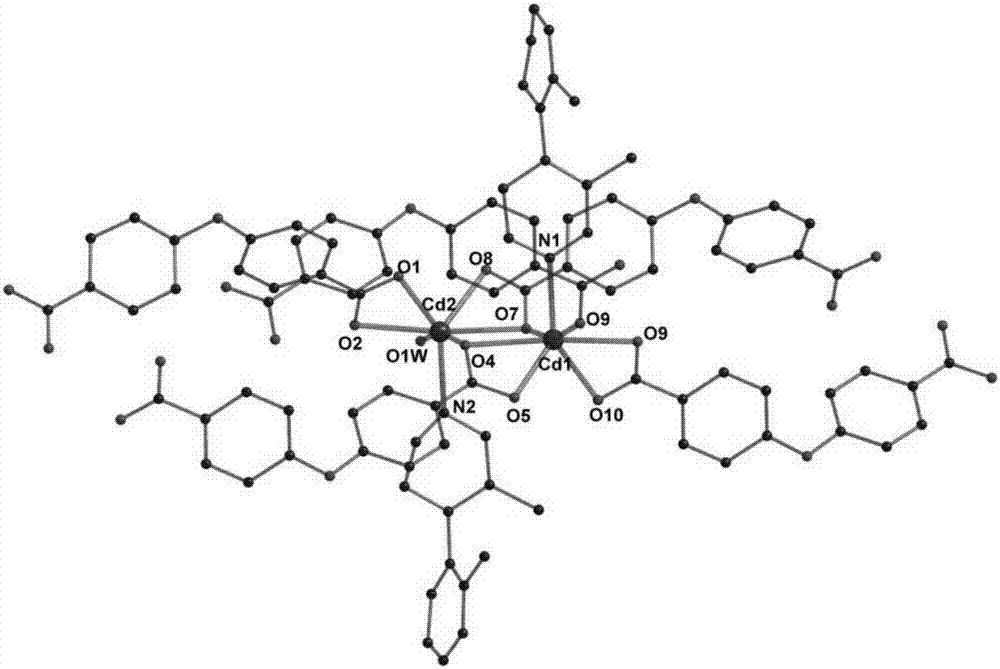

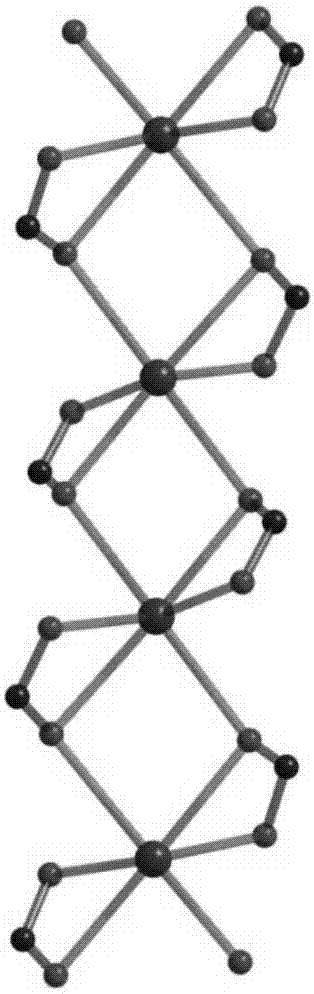

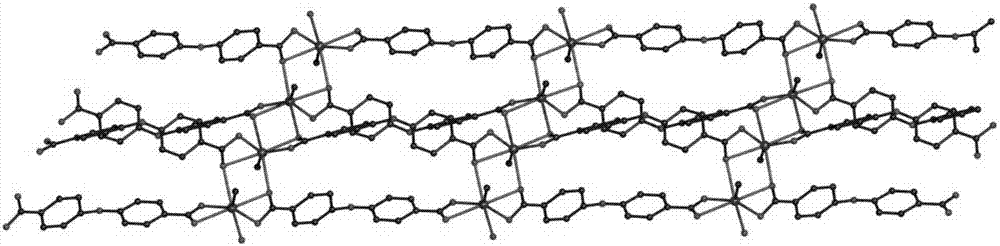

[0030] Example 1: Preparation of cadmium metal organic framework material according to the present invention

[0031] 1. Preparation of cadmium metal organic framework materials with selective adsorption of carbon dioxide gas and stable water resistance:

[0032] (1) Prepare hot alkaline water with pH=7-8, measure 10mL

[0033] (2) Weigh 0.3mmol H 2 oba (4,4'-oxybibenzoic acid) and 0.15 mmol dmbpy (3,3'-dimethyl-4,4'-bipyridine) were added to the above solution together;

[0034] (3) Weigh 0.3mmol Cd(NO 3 ) 2 4H 2 O, add ethanol 5mL again, add in the above-mentioned solution together;

[0035] (4) Add the substance in step 3 into a 23mL polytetrafluoroethylene reactor, and keep it at 130°C for 72 hours under autogenous pressure. -1 Cool down to room temperature;

[0036] (5) the product that step 4 is obtained is filtered, after collecting crystal and drying, obtain colorless crystal (according to H 2 Oba calculates its yield: 48%).

[0037] 2. Characterization of cad...

Embodiment 2

[0049] Example 2: Research on thermal stability and chemical stability of cadmium metal organic framework material according to the present invention

[0050] The cadmium metal-organic framework material prepared in Example 1 was used to conduct research on thermal stability and chemical stability, and the specific methods are as follows:

[0051] 1. Research on the thermal stability of cadmium metal-organic framework materials that selectively adsorb carbon dioxide and are stable against water:

[0052] Weigh 3mg of the prepared cadmium metal organic framework material and the activated cadmium metal organic framework material respectively, and measure their thermal stability in the range of 25-800°C at a heating rate of 10°C / min.

[0053] The result is as Figure 5 Shown: when the cadmium metal organic framework material is at about 200 ℃, it loses 2 free ethanol molecules and 4 lattice water molecules in the coordination environment, and the mass loss is about 14.86%; at 2...

Embodiment 3

[0060] Example 3: Research on Selective Gas Adsorption of Cadmium Metal Organic Framework Materials According to the Present Invention

[0061] The cadmium metal-organic framework material obtained in Example 1 was used to carry out the research on gas selective adsorption, and the specific method is as follows:

[0062] The activated cadmium metal-organic frameworks have been studied on CO at 298K 2 ,CH 4 ,CO,O 2 ,N 2 and H 2 adsorption properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com