Double-system heat pump defrosting method and device

A dual-system, heat pump technology, applied in lighting and heating equipment, damage protection, refrigeration components, etc., can solve the problems of insufficient heat absorption, reduced system safety, protective shutdown of the heat pump host, etc., to achieve low cost and structure Simple and safe system operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In conjunction with accompanying drawing, provide embodiment of the present invention as follows:

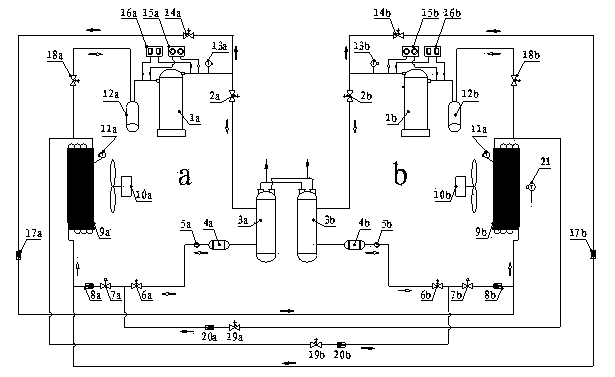

[0015] Such as figure 1 As shown: the dual-system heat pump defrosting device described in this embodiment includes two heating circuits and two sets of defrosting mechanisms. The composition and operation mode of the two heating circuits (a system heating circuit and b system heating circuit) are the same, including compressor 1a / 1b, auxiliary solenoid valve 2a / 2b, water-cooled condenser 3a / 3b, Dry filter 4a / 4b, sight glass 5a / 5b, heating solenoid valve 6a / 6b, expansion valve 7a / 7b, heating check valve 8a / 8b, finned evaporator 9a / 9b, axial fan 10a / 10b, gas-liquid separator 12a / 12b, exhaust temperature sensor 13a / 13b, high and low pressure gauge 15a / 15b and high and low pressure controller 16a / 16b. The composition and operation mode of the two sets of defrosting mechanisms are also the same, including the fin temperature sensor 11a / 11b, the first defrosting solenoid va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com