Arsenic removal adsorbent and preparation method thereof

A technology of adsorbent and stabilizer, which is applied in the field of arsenic removal adsorbent and its preparation, can solve the problems of difficult regeneration, small adsorption capacity, slow adsorption rate, etc., and achieve the effect of rapid adsorption removal, small particle size and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

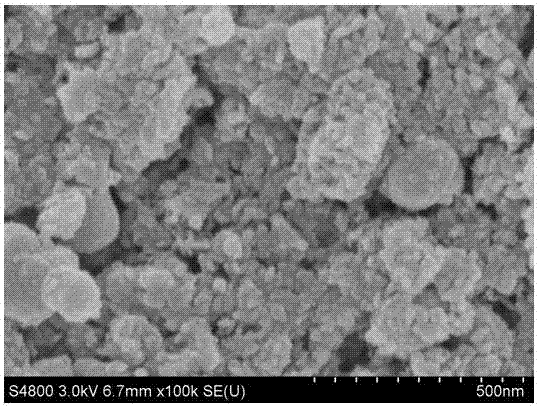

Embodiment 1

[0040] A preparation method for removing arsenic adsorbent, said method comprising the following steps:

[0041] Step 1: preparing a magnesium-aluminum metal salt mixed solution with a molar concentration of 1 mol / L, the molar ratio range of magnesium to aluminum in the magnesium-aluminum metal salt mixed solution is 2:3; the magnesium-aluminum metal salt is magnesium nitrate and aluminum nitrate.

[0042] Step 2: prepare the mixed alkaline solution that sodium hydroxide and sodium carbonate form, the molar concentration of sodium carbonate in the mixed alkaline solution is 2 times of the aluminum salt concentration in the magnesium aluminum metal salt mixed solution, the molar concentration of sodium hydroxide is magnesium aluminum 1.6 times the total concentration of metal ions in the metal salt mixed solution;

[0043] Step 3: drop the magnesium-aluminum metal salt mixed solution and the mixed alkali solution into the deionized water at the same constant drop rate, and keep...

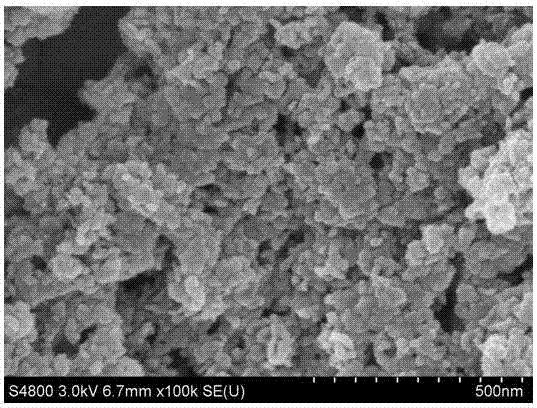

Embodiment 2

[0053] A preparation method for removing arsenic adsorbent, said method comprising the following steps:

[0054] Step 1: prepare a magnesium-aluminum metal salt mixed solution with a molar concentration of 1.2mol / L, the molar ratio range of magnesium to aluminum in the magnesium-aluminum metal salt mixed solution is 5:1; the magnesium-aluminum metal salt is aluminum nitrate and magnesium nitrate .

[0055] Step 2: prepare the mixed alkaline solution that sodium hydroxide and sodium carbonate form, the molar concentration of sodium carbonate in the mixed alkaline solution is 2 times of the aluminum salt concentration in the magnesium aluminum metal salt mixed solution, the molar concentration of sodium hydroxide is magnesium aluminum 1.6 times the total concentration of metal ions in the metal salt mixed solution;

[0056] Step 3: drop the magnesium-aluminum metal salt mixed solution and the mixed alkali solution into the deionized water at the same constant drop rate, and keep ...

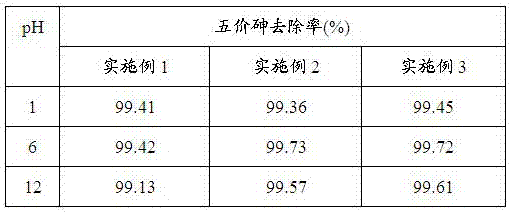

Embodiment 3

[0066] A preparation method for removing arsenic adsorbent, said method comprising the following steps:

[0067] Step 1: Prepare a mixed solution of magnesium-aluminum metal salt with a molar concentration of 1.1 mol / L. The molar ratio of magnesium to aluminum in the mixed solution of magnesium-aluminum metal salt is 2:1; the magnesium-aluminum metal salt is aluminum sulfate and magnesium chloride.

[0068] Step 2: prepare the mixed alkaline solution that sodium hydroxide and sodium carbonate form, the molar concentration of sodium carbonate in the mixed alkaline solution is 2 times of the aluminum salt concentration in the magnesium aluminum metal salt mixed solution, the molar concentration of sodium hydroxide is magnesium aluminum 1.6 times the total concentration of metal ions in the metal salt mixed solution;

[0069] Step 3: drop the magnesium-aluminum metal salt mixed solution and the mixed alkali solution into the deionized water at the same constant drop rate, and kee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com