Chemical mix and delivery systems and methods thereof

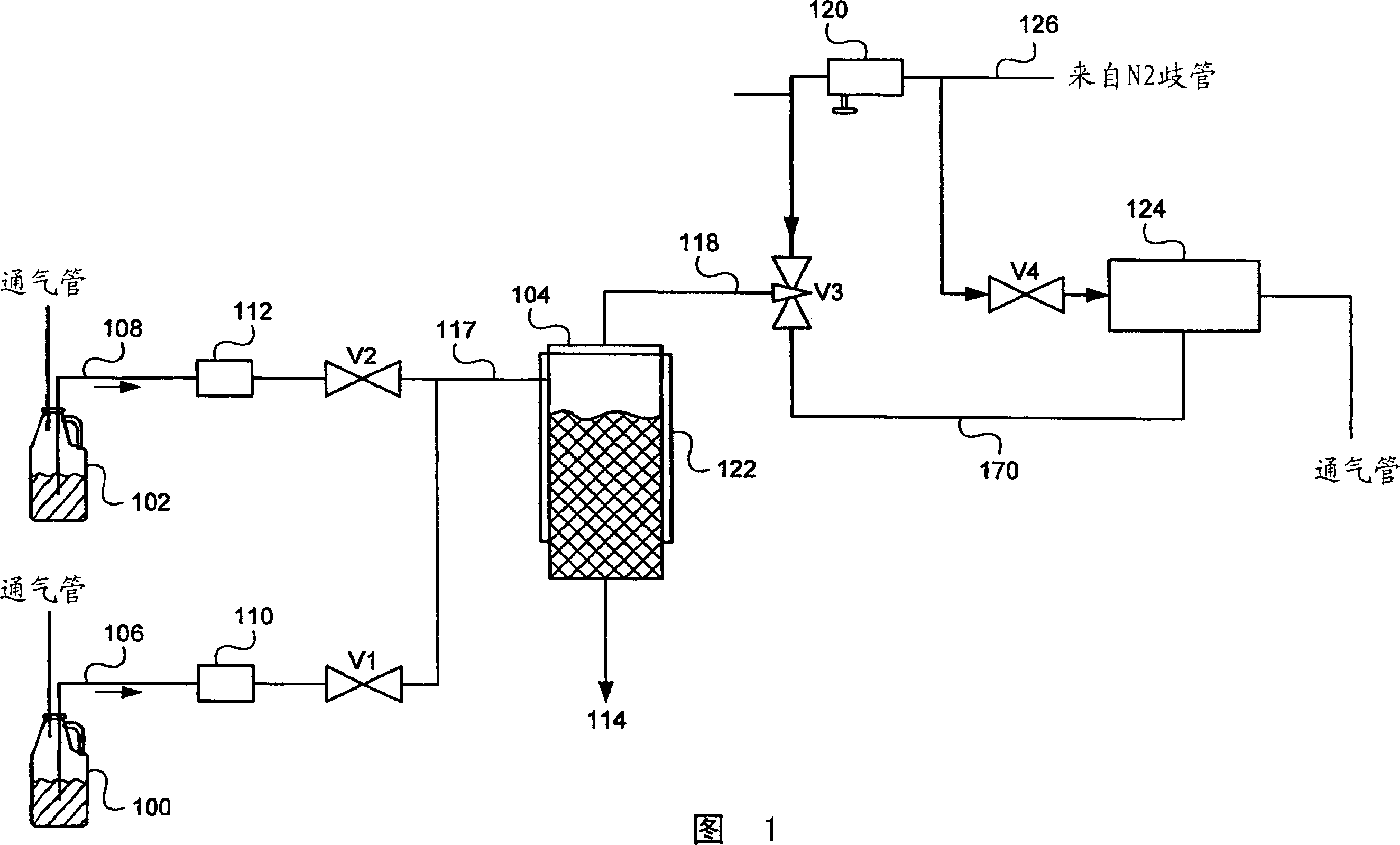

A technology for conveying systems, chemicals, applied in chemical instruments and methods, mixers, chemical/physical processes, etc., to solve problems such as obstruction of flow through, easy to change, flowmeter blockage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

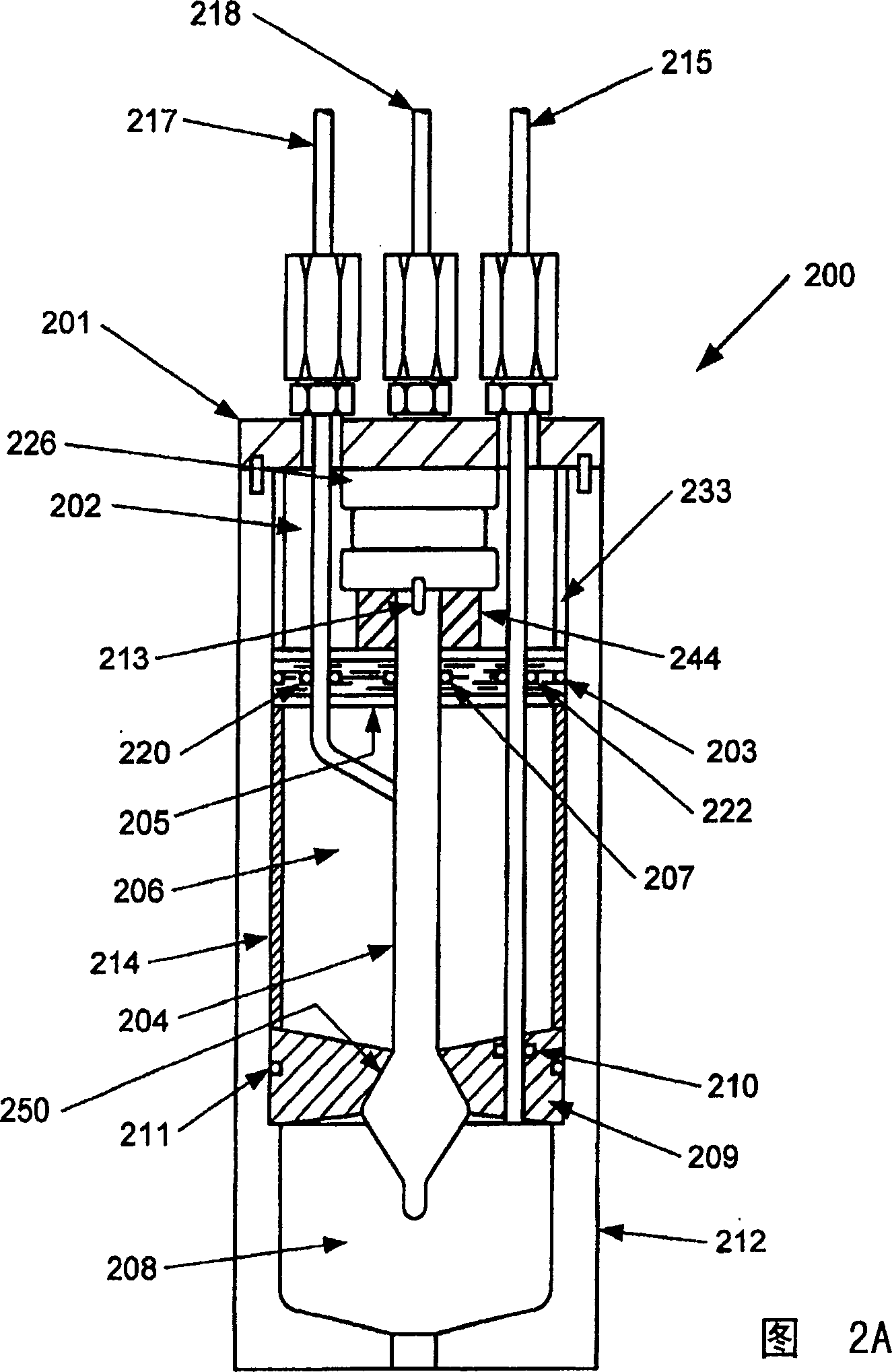

[0033] A first embodiment in accordance with the present invention includes a multi-tank load sensor assembly 200 as shown in FIGS. 2A-2B . The assembly 200 can be as image 3 Part of the system shown, and can replace the problematic single tank 104 and bubble sensors 110, 112 shown in FIG.

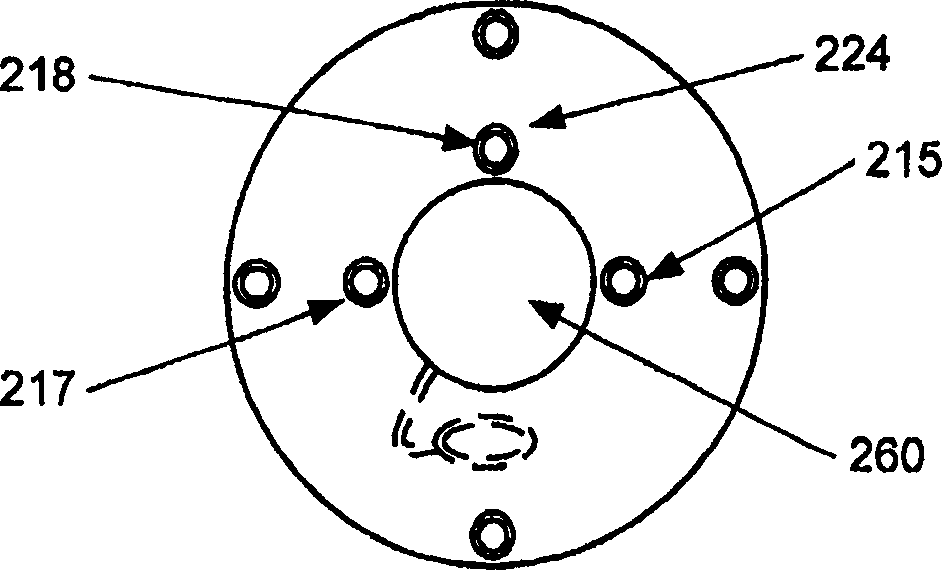

[0034] In this embodiment, the assembly 200, made of Teflon, SST, polypropylene, or any chemically compatible material, includes the upper compartment 202, the main tank 206, and the surge tank all within the housing 912 208. The buffer storage tank 208 is in close contact with the main storage tank 206 through the partition 209 , and the O-ring 211 makes the periphery of the partition 209 closely contact with the casing 212 . A tapered central bore 250 is used in the diaphragm 209 to allow the inner seal shaft 204 to form a liquid and gas tight seal with the diaphragm 209 . The separator 209 forms a liquid-tight and air-tight seal with the pneumatic conduit 215 through an O-ring 210 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com